The model energy codes, in their various forms, have been at the forefront of the discussion regarding building design in recent years. These codes include the International Energy Conservation Code (IECC), which was first issued in 2000, and ASHRAE Standard 90.1, which dates back to 1974. Together, these model codes provide the basis for the state and local building codes that govern the required energy efficiency of newly constructed and altered buildings.

These codes are having an increasingly profound effect on the way new building enclosures are designed, and how they ultimately perform. With each subsequent round of energy code issuance, measurable gains in energy efficiency and cost savings are achieved—and this is typically on top of recent codes that were already reasonably efficient.

LEARNING OBJECTIVES

After reading this article, you should be able to:

• Identify the energy codes that apply to existing buildings, and explain the challenges that arise when applying current codes to older building enclosures.

• Analyze considerations for existing buildings with high percentages of vertical fenestration to address the constraints of applying trade-off methods.

• Define “sub-optimization” in terms of fragmentary and haphazard application of the energy code.

• Explain the concept of fuzzy decision making as it applies to interpretation of the energy code.

EDITOR’S NOTE

This concludes the reading required for this course. To earn 1.0 AIA CES HSW learning units, study the complete article carefully and take the 10-question exam posted at www.BDCnetwork.com/EnergyCodes.

For example, in September 2014 the U.S. Department of Energy determined that the recently issued ASHRAE Standard 90.1-2013 would achieve energy savings over the previous 2010 edition of 8.7% in energy costs, 7.6% in site energy consumption, and 8.5% in source energy use, which includes the site energy, as well as the entire production, transmission, and delivery process. In August 2013, the DOE determined that the 2012 edition of the IECC would achieve energy savings over the previous 2006 edition of 17% in energy costs and 24% in site energy consumption. These are not insubstantial gains, especially considering that earlier versions of the model codes had energy savings over their respective preceding editions. This compounding of energy savings through subsequent editions of the code illustrates the large-scale improvements being made in the efficiency required by the energy codes.

Buildings built to the prevailing model energy codes as recently as 1999 generally consume 67% more energy than those built today—and it gets worse for buildings that are even older. Of course, the construction of pre-1999 buildings shouldn’t be held to a standard that didn’t exist at their time of construction, but that’s precisely the point. These buildings far underperform new ones in terms of energy efficiency, yet they constitute the bulk of the existing building stock. They could very well continue to consume higher levels of energy over the course of their 50- to 100-year life expectancy.

The broader goals for improving the energy efficiency of the built environment should not be limited to optimizing the performance of new buildings as we build them, since this is an additive solution. The industry should seek to reduce the energy consumption of the building stock as a whole. To do this, there needs to be greater emphasis on increasing the energy efficiency of existing buildings, which is a substitutive solution. If the goal is to reduce overall consumption at an aggregate level, substitutive solutions have a potential for greater impact than additive ones.

With all of the successes that are being achieved at a policy level with regard to new construction, finding ways to best parlay these achievements to our existing building stock is of growing importance.

The model energy codes address existing building enclosures, but often only to a limited extent. The manner in which they deal with existing buildings is binary—either the code applies or it doesn’t—and there’s little structure in place to deal with the many particulars that are unique to the nature of work performed on existing buildings.

When applying current energy codes to existing buildings, a number of issues arise, particularly where the building exterior is concerned. Building enclosures are extraordinarily important for energy efficiency, given that building enclosure performance is often a function of the overall building design.

Moreover, envelope assemblies tend to have long life cycles, which can make them difficult and costly to effectively upgrade. If not designed or rehabilitated efficiently, building enclosures can have lasting effects on energy consumption.

Top Issues with Energy Codes

In many cases, compliance with the energy code is pretty straightforward when altering existing enclosures. It’s as simple as looking up the performance targets in a table. Published in the codes, these tables specify performance targets—such as thermal conductivity (U-factor), thermal resistance (R-value), solar heat gain (SHGC), and air leakage rates—that need to be met by the portions of the enclosure to be altered. This approach to compliance is called the prescriptive path.

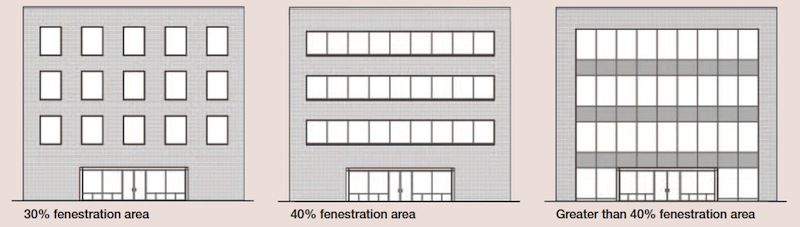

Problems arise with existing buildings that have vertical fenestration (windows, glazed doors, curtain walls, storefronts, etc.) in excess of 30–40% of the wall area, depending on the code. There are many buildings that have this potential complication, yet it is often overlooked. These highly glazed existing buildings represent a significant portion of the energy drain in our building stock. In these instances, alterations to the enclosure do not meet the criteria in the IECC to use the prescriptive path approach.

Instead, design professionals and owners must use the Building Envelope Trade-Off Option or the Energy Cost Budget Method outlined in ASHRAE 90.1. Both are part of a balanced approach to enclosure design, where compliance depends on trade-offs between related components and systems. These approaches allow design professionals to compensate for inefficient assemblies with other systems that outperform the standard. Inefficiencies of the parts can then be tolerated as long as efficiency of the whole is achieved.

Air leakage testing can identify components in need of increased airtightness to improve energy efficiency.

Air leakage testing can identify components in need of increased airtightness to improve energy efficiency.

This is an excellent approach for new building enclosures, as it allows for greater flexibility in design. For existing building enclosures with significant fenestration area, on the other hand, offsetting the inefficiency of the fenestration may be necessary when making alterations to the building enclosure, by either identifying compensatory efficient systems elsewhere in the building, or by further increasing the efficiency of the altered components.

Achieving building envelope trade-offs in an existing building can be difficult, as other efficiencies may or may not exist elsewhere in a building. Even if they do, they may be unknowable. Compensating for the excess fenestration area through increased efficiency of the altered portion of the building alone may be prohibitively costly or beyond feasibility.

The same issue described above occurs when alterations are made to existing skylights that exceed 3% of the roof area (or 5% with daylighting controls).

Much of the focus in the codes concerning areas of vertical fenestration is, for good reason, due to the generally higher conductivity of fenestration assemblies compared to that of wall assemblies. Also, it is generally less expensive to add insulation to walls than it is to incorporate the same level of thermal resistance into fenestration.

The codes’ emphasis on smaller fenestration area makes sense, because higher insulating values can be more easily achieved in opaque wall areas.

Imposing greater limits on the vertical fenestration area shifts the importance of the enclosure performance toward the walls. However, the codes are limited in regard to the renovation of existing building walls, as the requirements for insulating walls are very narrow, or even nonexistent. In most cases, alterations to existing walls are exempt from compliance with the energy code unless new framing cavities are added.

Even then, bringing the wall into full compliance with the code requirements can be difficult. Due to existing physical constraints from surrounding construction, it often isn’t practical—or possible—to achieve the equivalent effectiveness of the code’s insulation requirements, even when new framing is added. This none-or-total requirement ultimately leaves a vacuum in the energy code that tends to fill with alterations of varying effectiveness, depending largely on the motivation, experience, and intent of the owner and design professional.

The obstacles with existing buildings are nuanced and particular. It is especially difficult to address these nuances in the framework of a code designed for new construction, because the success of a new enclosure design is so dependent on the functioning and balancing of the building envelope as a whole.

For existing buildings, the comprehensive nature of good enclosure design is often in direct conflict with the inherently fragmentary nature of repairs and alterations. The vagueness that results from this conflict can run the risk of sub-optimization and requires some fuzzy decision making, which is worth exploring a bit further.

The dangers of sub-optimization: Improvement for the worse

Sub-optimization is a concept that is the engineering version of irony, except highly technical and without humor. Nevertheless, it’s something we encounter all the time in many aspects of design, manufacturing, business, and everyday life. Sub-optimization is when the better performance of a part ends up making the overall performance of the system worse. It’s what happens in manufacturing when faster production leads to oversupply or quality control problems, or how correcting everybody’s conversational grammar mistakes kills conversations.

The fragmentary nature of alterations to existing enclosures can run this same risk of unintended consequences when partial elements of the energy code are applied in an ad hoc fashion, rather than in a balanced approach to the system as a whole. Code development organizations and enforcement agencies are not unaware of the problem. The New York City Department of Buildings, for example, has issued a bulletin clarifying that compliance with the NYC Energy Conservation Code is not required if it will compromise the building envelope’s resistance to condensation, freeze-thaw damage, or mold.

The risks of sub-optimization are real, but they don’t necessarily justify forgoing the work. Adding insulation and increasing the airtightness of existing building enclosures is important, but they should never be done without regard to the broader consequences.

Improved understanding of the issues facing existing building enclosures will lead to more robust energy standards and guidelines.

Improved understanding of the issues facing existing building enclosures will lead to more robust energy standards and guidelines.

Adding insulation to an assembly changes the way that it manages moisture, as well as the temperature profile across the building component. It may dry out more slowly, allowing moisture to accumulate. Insulation in the wrong locations within a wall assembly may leave some parts of the wall colder than others, which can increase the risk of condensation or freeze-thaw damage. The potential for increased moisture accumulation, condensation, and freeze-thaw should be reviewed carefully when adding insulation to an existing wall assembly.

Similarly, increasing the airtightness of an exterior wall through the addition of an air barrier can dramatically improve the energy performance of a building, but it can result in sub-optimization if done indiscriminately. Older mechanical systems were often designed to an assumed level of outside air infiltration for make-up air, so care must be taken to balance existing mechanical systems when making a substantial change to the airtightness of an enclosure. Indoor air quality and make-up ventilation levels should be maintained or improved, and the design professional should confirm that existing combustion elements won’t backdraft due to changes in building pressure.

Each iteration of the energy codes aims to better address problems that arise from piecemeal or one-size-fits-all energy upgrades, but optimizing the standards can be a lengthy process that sometimes has lingering effects. A good example is the requirement for high-albedo roof membranes (i.e., cool roofs), which were compulsory in all climates in ASHRAE 90.1-2007, but limited to southern climates in ASHRAE 90.1-2010. One reason for this change, presumably, is that benefits from reduced interior heat gain from cool roofs may be less certain in heating-dominated northern climates.

On the design side, substantial efficiency can be lost when alterations or replacements are executed without consideration for adjoining elements. Often, budgets are diverted to high-efficiency materials in a new assembly, but the performance gains are then rendered moot when there is no funding left for quality materials, design, and workmanship in the surrounding components. For example, a lot of money can be spent on energy-efficient windows, but if the efficient window is placed in a value-engineered wall opening that is highly conductive or insufficiently airtight, then the overall system performance may be worse than it was before the upgrade.

We’ve investigated instances where new, highly thermally insulated curtain walls were installed adjacent to wall assemblies that were drafty and highly conductive. The result was that the high-performance curtain wall frame became so cold in winter that ice formed on the inside surfaces.

Designers and owners should be aware of the risks of sub-optimization due to a narrow focus on individual components, as opposed to a broad understanding of balanced and complete design.

How Fuzzy Decision making Can impact Performance

Fuzzy decision making accounts for decisions that we have to make where the logic isn’t strictly true or false, which is to say, the vast majority of decisions in design and construction. In the case of energy codes, the parameters for making a decision about enclosure alterations for an existing building may be unclear for a number of reasons: more than one energy code may or may not apply; the energy codes are intended for a new building; the building has too much glass, so compensatory efficiencies in unknown existing systems must be determined in order to achieve code compliance; the building may be exempt altogether, or it may have to comply with all provisions of the code, and the difference is razor-thin and a bit unclear. The building owner or manager may want to do the right thing, but even adding insulation to existing walls could have unintended consequences. This scenario may rightfully make even the most environmentally conscious Building Team throw up their hands in frustration.

Is this lack of clarity the fault of the code? No, it’s not. The code doesn’t design buildings, people do, and ambiguity is inevitable when something general has to apply to every particular. Regardless, code compliance is required, and real decisions need to be made with regard to work on existing buildings.

Much of the confusion described above is due to discrepancies between the letter of the code and its interpretation. Some of this is dealt with when building departments and code officials issue clarifications, yet sometimes things go unaddressed. In some cases, amendments and clarifications can have the opposite effect, and even add to the confusion, drawing inferences about the meaning and intent of the code beyond the words on paper. It is too much to ask from a code because judgments rendered from a central authority, regardless of how many are issued, can never fully account for all possibilities and specifics. In the face of necessarily vague requirements, some level of fuzzy decision making will result.

The hurdle that building owners and design professionals confront when making these fuzzy decisions is that cost is almost always a driving factor. For example, the codes are not clear as to the extent to which the insulating value of an assembly needs to account for conditions beyond the most basic elements of the assembly itself. When the effectiveness of a building component, such as an exterior wall, is compromised by elements that are highly conductive, such as balcony projections, the result is a thermal bridge, or heat loss pathway. These thermal bridges happen at places such as corners, window perimeters, interfaces, balconies, parapets, and floor lines, but, despite their prevalence, they aren’t really addressed as part of the basic assemblies discussed in the codes.

Do thermal bridges have a measurable impact? Substantially. Are existing buildings riddled with thermal shorts? Usually. Should they be taken into account when evaluating the energy efficiency of an enclosure? Of course. Does it cost more to account for all these thermal bridges? You bet. Does the code require that they be accounted for, and if so, to what extent? Well, that’s largely unaddressed, so a fuzzy decision has to be made.

Resolving thermal bridges can add cost to a project, but ignoring them may cost even more, in terms of heat loss and increased energy costs, as well as freeze-thaw cycling, condensation, and moisture-related damage. While not perfect, there are practices and guidelines emerging that do a good job of approximating how thermal bridges impact building enclosures. These methodologies should be taken into account when designing building envelope upgrades.

Although there isn’t an absolute true or false answer to the question of energy code compliance at this point, there should be a spectrum within which a responsible design professional can make an appropriate and informed design decision, in consultation with owners and code officials, without relying entirely on the altruism of the stakeholders or the written limitations of the code. The solution does not always lie in centrally defined rules and regulations, but rather in design teams that are motivated to achieve energy performance goals through a self-regulating culture of professional ethics and responsibility. Good building design, especially good existing building design, is really performed on a case-by-case basis.

Codifying Enclosure Retrofits

The good news is there are lots of positive things happening. We’re not quite at the point yet where there is industrywide consensus on what should be done when altering existing building enclosures—at least not to the extent that guidelines can be codified—but things are moving in the right direction. There is a greater understanding of the issues, often initiated through academic, government, or private research and testing, and evolving into industry standards and guidelines, government programs, updated changes to energy codes, and general practice. There is much more discussion today throughout the construction industry about the importance of building enclosures as they relate to energy performance. All of this dialogue is important.

Even though the energy performance debate is often focused on new construction or high-profile projects, key findings and concepts still find their way into the work on existing buildings. The substantial gains in overall performance targets that new buildings and high-performance retrofits are achieving will eventually translate into improved efficiency for everyday existing buildings, so that the impact of energy conservation measures can be assessed at the mean.

This effort will help build the momentum needed to bring about a shift in the problem of energy consumption of the existing building stock. As consensus builds among stakeholders as to what should be done, the vagueness and inconsistencies currently plaguing the codes will give way to improved clarity and comprehensive design. When that starts to happen, addressing challenges that arise with regard to energy code compliance becomes a decision-making process that is much less fuzzy. All of this is good reason for optimism.

About the Author: Bradley Carmichael is Senior Engineer with Hoffmann Architects (www.hoffarch.com), specializing in the rehabilitation of building exteriors. He develops thermal models, conducts performance assessments, and provides energy analysis both in consultation for new construction and in designing upgrades to existing buildings.

EDITOR’S NOTE

This concludes the reading required for this course. To earn 1.0 AIA CES HSW learning units, study the complete article carefully and take the 10-question exam posted at www.BDCnetwork.com/EnergyCodes.

Percent Fenestration Area for Code Compliance

The percent fenestration area of vertical exterior walls is one of the common prescriptive requirements dictated by the energy code. Each code has a maximum allowable percent fenestration area for the vertical wall that allows for use of the prescriptive path to compliance. These maximum areas are 40% for ASHRAE 90.1-2010 and IECC 2009, and 30% for IECC 2012. Vertical fenestration includes the glass and non-glass components of all windows, curtain walls, storefronts, doors, and entrances.

If the fenestration area of a building exceeds the stated maximum, energy code compliance must be calculated using an alternative option from ASHRAE 90.1, such as the Building Envelope Trade-Off Option or the Energy Cost Budget Method. Once the critical percentage of fenestration has been exceeded, the International Energy Conservation Code refers design professionals to the alternative methodologies from ASHRAE 90.1.

Similar restrictions are in place for skylights.

IECC vs. ASHRAE 90.1: A brief comparison of energy codes

The two prevailing energy codes are the International Energy Conservation Code (IECC), produced by the International Code Council, and ANSI/ASHRAE/IESNA Standard 90.1, developed jointly by the American National Standards Institute, the American Society of Heating, Refrigerating and Air-Conditioning Engineers, and the Illuminating Engineering Society of North America. Technically, ASHRAE 90.1 is a standard, not a model code, but some jurisdictions adopt it as a code.

The IECC is a model code developed as part of the family of International Codes produced by the International Code Council, which includes other commonly adopted codes such as the International Building Code. The IECC has been adopted for commercial buildings by 47 states, as well as Washington D.C., New York City, Puerto Rico, and the U.S. Virgin Islands. Minnesota and Indiana have adopted ASHRAE 90.1 instead of the IECC. California has its own energy code, which surpasses the requirements of both model codes.

Once adopted by states, the energy codes often still need to be adopted and enforced by local governments at the jurisdictional level.

Even for states that have adopted the IECC, ASHRAE 90.1 is still relevant. The IECC accepts ASHRAE 90.1 as a suitable path for compliance for commercial buildings, and, as ASHRAE 90.1 has a number of more flexible paths to compliance than the IECC does, there are instances when a design professional would be required to use the energy performance calculation methods from ASHRAE 90.1 in lieu of those in the IECC.

Related Stories

| Mar 2, 2012

By the Numbers

66 skyscrapers to built in China over six years; 1,000 questions in the Modern Architecture game; 21,000 new jobs.

| Mar 1, 2012

AIA: A clear difference, new developments in load-bearing glass

Earn 1.0 AIA/CES learning units by studying this article and successfully completing the online exam.

| Mar 1, 2012

Bomel completes design-build parking complex at U.C. San Diego

The $24-million facility, which fits into a canyon setting on the university’s East Campus, includes 1,200 stalls in two adjoining garages and a soccer field on a top level.

| Mar 1, 2012

Reconstruction of L.A.’s Dunbar Hotel underway

Withee Malcolm Architects’ designs for the project include the complete renovation of the Dunbar Hotel and the Somerville Apartments I and II.

| Feb 28, 2012

Roofing contractors recognized for workmanship

Sika Sarnafil announces Project of the Year winners; competition highlights visually stunning, energy efficient, and sustainable roofs.

| Feb 26, 2012

Milwaukee U-Haul facility receives LEED-CI Silver

The new elements of the facility now include: efficient lighting with day-lighting controls and occupancy sensors, a high-efficiency HVAC system used in conjunction with a newly constructed thermal envelope to help reduce energy consumption, and the installation of low-flow fixtures to reduce water consumption.

| Feb 22, 2012

Siemens earns LEED certification for Maryland office

The Beltsville facility, which also earned the ENERGY STAR Label for energy performance, implemented a range of energy efficiency, water conservation and sustainable operations measures as part of the certification process.

| Feb 22, 2012

Suffolk awarded Boston post office renovation project

Renovation of art deco landmark will add 21,000 square feet of retail and 110 new parking spaces.

| Feb 20, 2012

Comment period for update to USGBC's LEED Green Building Program now open

This third draft of LEED has been refined to address technical stringency and rigor, measurement and performance tools, and an enhanced user experience.

| Feb 17, 2012

Tremco Inc. headquarters achieves LEED Gold certification

Changes were so extensive that the certification is for new construction and not for renovation; officially, the building is LEED-NC.

![Applying modern energy codes to building envelope retrofits [AIA course] Applying modern energy codes to building envelope retrofits [AIA course]](/sites/default/files/OPENERHoffmann9.jpg)