A few months ago, the world’s first self-described “Marschitect” was working on developing architecture designed specifically to meet the challenges of living on Mars. Now, more and more architects and researchers are taking a shot at developing new and innovative ways for building habitable environments on the surface of the inhospitable planet.

Two of the most recent ideas for potential building materials come from NASA researchers and a team of scientists at Illinois’s Northwestern University.

As Occam’s razor states, the simplest solution is usually the right one, and NASA researchers have taken that idea to heart as they believe the building material that may help solve many of the problems associated with living and building on Mars is regular, everyday ice, csmonitor.com reports.

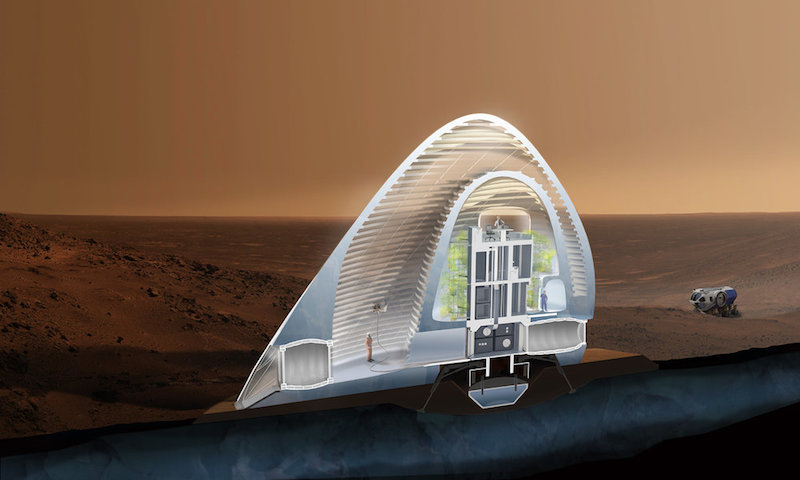

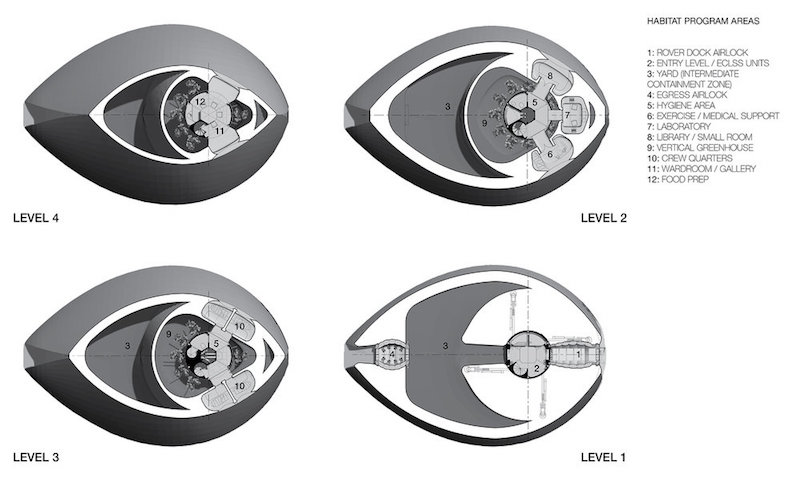

NASA’s Langley Research Center in Hampton, Va., recently revealed its design concept for the “Mars Ice Home,” which was developed with help from Space Exploration Architecture and the Clouds Architecture Office.

An inflatable inner-tube-like material would provide the actual living quarters for the astronauts while its exterior would be encased in a shell of 3D-printed ice. The ice would protect the structure, and those living within it, from cosmic rays, which are one of the biggest health concerns associated with humans living on Mars. While the ice structure would block the cosmic rays, it would still allow some light to pass through so it would more closely resemble living in a home than a cave or underground and allowing the astronauts to stay connected to natural diurnal cycles.

Cross section of the Mars Ice House. Courtesy of Space Exploration Architecture.

Cross section of the Mars Ice House. Courtesy of Space Exploration Architecture.

The ice shell would be five centimeters thick and is envisioned as a series of nested domes enclosed by a transparent ETFE (Ethylene tetrafluoroethylene) membrane. The outer shell creates a “front yard” that astronauts can occupy without the use of an EVA suit. The inner shell will provide a vertical hydroponic greenhouse that surrounds the inhabitants.

The Mars Ice House would be constructed without the need of a crew being present. The module would descend to the planet’s surface and land. Then the construction process would begin: the foundation is sintered, the ETFE membrane is inflated, the airlocks are deployed, the ice for the outer and inner shells is printed, and the plant-growing process beings. Only after all of this occurs does the crew arrive.

Since one of the biggest hurdles to building on Mars revolves around transporting any possible building materials to the planet, the lightness of the inflatable structure and the availability of ice on Mars make the Mars Ice Home a very intriguing possibility.

Courtesy of Space Exploration Architecture.

Courtesy of Space Exploration Architecture.

Another proposal for building on Mars uses the planets limited resources, as well, but instead of ice, a team of scientists from Northwestern University developed a form of “Martin concrete” that can be created using soil from the Red Planet, Dezeen reports.

The concrete is created by mixing the soil with molten sulfur and, according to the scientists, could be used to build entire villages on Mars. Most importantly, the concrete doesn’t require any water to make. The building material can endure low temperatures, is resistant to acid and salt, and can be melted down and recycled to build a different structure.

The idea of using the soil found on Mars to create a building material is not a new one. Foster + Partners created a concept for a 3D-printed habitat built by robots that uses regolith, loose soil, and rocks as the building materials, but according to Dezeen, this is the first time a report has detailed how this could actually be feasible.

After a series of trial and error experiments, the team, consisting of Lin Wan, Roman Wendner, and Gianluca Cusatis, determined an even mix of sulfur and aggregate would produce a material with a strength of 50 megapascals. When the difference of gravity on the surface of Mars is factored in, the material will be three times stronger, making it suitable for building on Mars.

The time it takes to travel to Mars makes the necessity of building a habitat for the astronauts on its surface unavoidable. While the development of Martian architecture may seem like nothing more than an exercise in creativity, it is actually an integral part of one day setting foot on Mars.

The "front yard" of the Mars Ice House. Courtesy of Space Exploration Architecture.

The "front yard" of the Mars Ice House. Courtesy of Space Exploration Architecture.

Foster + Partners' 3D-printed proposal. Courtesy of Foster + Partners.

Foster + Partners' 3D-printed proposal. Courtesy of Foster + Partners.

Related Stories

| May 14, 2014

Prefab payback: Mortenson quantifies cost and schedule savings from prefabrication techniques

Value-based cost-benefit analysis of prefab approaches on the firm's 360-bed Exempla Saint Joseph Heritage Project shows significant savings for the Building Team.

| May 13, 2014

19 industry groups team to promote resilient planning and building materials

The industry associations, with more than 700,000 members generating almost $1 trillion in GDP, have issued a joint statement on resilience, pushing design and building solutions for disaster mitigation.

| May 2, 2014

Norwegian modular project set to be world's tallest timber-frame apartment building [slideshow]

A 14-story luxury apartment block in central Bergen, Norway, will be the world's tallest timber-framed multifamily project, at 49 meters (160 feet).

| May 1, 2014

Tight on space for multifamily? Check out this modular kitchen tower

The Clei Ecooking kitchen, recently rolled out at Milan's Salone de Mobile furniture fair, squeezes multiple appliances into a tiny footprint.

| Apr 25, 2014

Recent NFPA 80 updates clarify fire rated applications

Code confusion has led to misapplications of fire rated glass and framing, which can have dangerous and/or expensive results. Two recent NFPA 80 revisions help clarify the confusion. SPONSORED CONTENT

| Apr 9, 2014

Steel decks: 11 tips for their proper use | BD+C

Building Teams have been using steel decks with proven success for 75 years. Building Design+Construction consulted with technical experts from the Steel Deck Institute and the deck manufacturing industry for their advice on how best to use steel decking.

| Apr 8, 2014

Fire resistive curtain wall helps The Kensington meet property line requirements

The majority of fire rated glazing applications occur inside a building to allow occupants to exit the building safely or provide an area of refuge during a fire. But what happens when the threat of fire comes from the outside? This was the case for The Kensington, a mixed-use residential building in Boston.

| Apr 8, 2014

Reflecting on job number 61-001

Job number 61-001 changed everything. It was sold in 1961, a year of change for the nation and for Star. By January, John F. Kennedy would be president. By the end of the year, Star would launch a historic shift in our product and our distribution, a shift still active today.

| Apr 2, 2014

8 tips for avoiding thermal bridges in window applications

Aligning thermal breaks and applying air barriers are among the top design and installation tricks recommended by building enclosure experts.

Sponsored | | Mar 25, 2014

Johns Hopkins chooses SLENDERWALL for a critical medical facility reconstruction

After decades of wear, the hand-laid brick envelope of the Johns Hopkins nine-story Nelson/Harvey inpatient facility began failing. SLENDERWALL met the requirements for renovation.