Today’s buildings use glass extensively in the envelope for its ability to provide clear views and natural daylighting. Advances in glazing technology over the years has allowed designers to specify glazing systems that are also energy efficient and noise mitigating. When needed, the same glazing system can also protect against fire due to lot line requirements – and in an area as densely populated as New York City, these situations happen more often than you think.

Determining when fire rated requirements apply, the type of fire rated glazing allowed, how much fire rated glazing can be used, and what happens when sprinklers are installed are just some of the issues that designers have to wrestle with. Tim Nass, our VP of National Sales, talked about this issue at the recently concluded Facades+ Performance Conference in New York City, which was attended by over 300 architects, building envelope consultants, general contractors, owners and developers. His presentation discussed Building Bulletin 2015-17, which was recently issued by the NYC Buildings Department to clarify the code requirements for lot line openings.

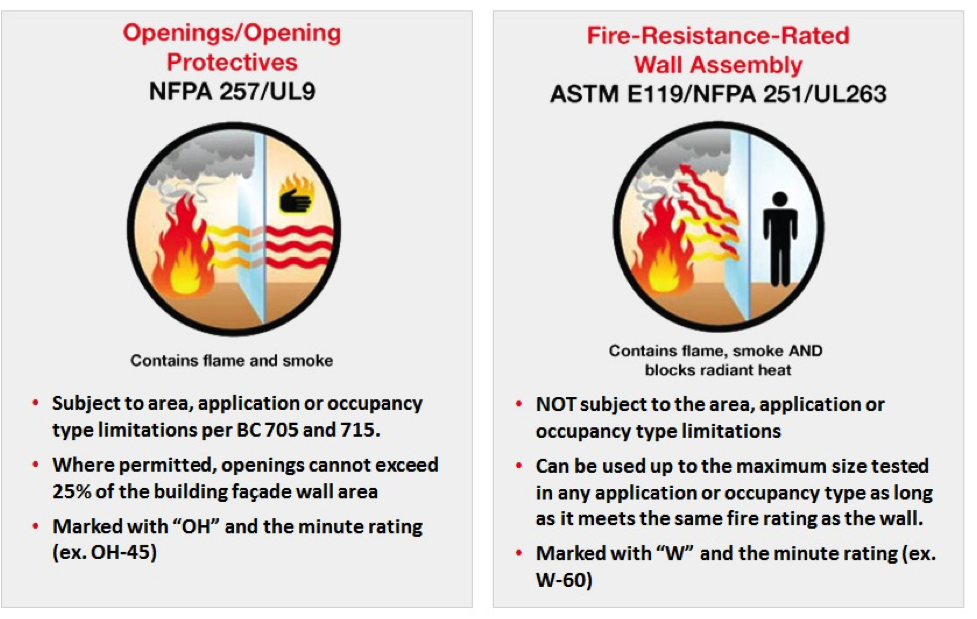

Section I talks about the limitations on fire protective glass used in openings and highlights important definitions for calculating fire separation distances that determine exterior opening limits. Once the fire separation distance has been established, BC Table 705.8 (Maximum Area of Exterior Wall Openings Based on Fire Separation Distance and Degree of Opening Protection) will be used to see if exterior openings are allowed, and how much. For the unlimited use of glazing, Section II states that fire resistive glazing assemblies tested to ASTM E119 are not considered openings, and therefore, can be used in all applications up to the maximum size tested. Fire resistive glazing can be used in areas where openings are either “Not Permitted” or constrained by area limitations per BC Table 705.8. This is because fire resistive glazing is not considered openings or fire windows, but rather, transparent wall assemblies. This is a very important distinction, and where an understanding of fire protective vs. fire resistive glazing products matter:

Click here to download the complete Consultant’s Guide to NYC BB 2015-17 and Fire Rated Exterior Openings

Using fire resistive glass in exterior applications where fire protective glass is either constrained by area limitations or not applies to the rest of the country as well, not just New York. The 2012 and 2015 International Building Code (IBC) Table 705.8 lays out the percentage of protected and unprotected openings and size limits allowed in exterior walls based on fire separation distance defined in Section. To exceed these limitations, fire resistive glazing or transparent wall assemblies must be used.

You can check out our case studies on exterior fire resistive wall assemblies at Midtown Community Court in New York, NY; The Kensington in Boston, MA; Kromrey Middle School in Middleton, WI; San Jose Downtown Health Center in San Jose, CA and Aspen Art Museum in Aspen, CO to name a few. If you have a current or upcoming project that required fire rated glazing, don’t hesitate to contact us online, call us toll-free at 888.653.3333 or reach out to your local SAFTI FIRST architectural representative for assistance.

More from Author

Bill O'Keeffe | Oct 19, 2020

Going virtual

Manufacturers use virtual platforms to help architects meet CEU requirements.

Bill O'Keeffe | Jul 16, 2020

Obsolete?

"Revolutional, affordable, USA made Fire Rated Glazing for all fire protective areas makes ceramic glazing obsolete". Check out SuperClear 45-HS and SuperClear 45-HS-LI to understand why!

Bill O'Keeffe | Feb 10, 2020

USA-made fire rated glazing goes big in 2020

We are pleased to announce and share that the second phase of this $8 million expansion, upgrading our fire rated glass manufacturing facilities in Merced, California, is underway.

Bill O'Keeffe | Nov 20, 2019

Demand for advanced, USA-made fire rated glazing “RAISES THE ROOF”

With architects specifying full-vision, code-compliant, 60 and 90 minute, temperature rise doors for exit stairwells and other code required applications, we found this as an opportunity to expand our product offerings.