I don’t know of any fire rated product that doesn’t have its limitations. So let’s be honest, advertisements urging designers to “be unlimited” when it comes to using glass ceramics, or any other fire protective glazing, are misleading. Especially when they tout fire ratings up to 3 hours.

While I understand the advertiser’s message of asking designers to think outside the box and use glass where it hasn’t been used before, I think it’s important for designers to realize that fire rated glass – especially glass ceramic – does have its limits under the International Building Code (IBC). One only has to look at the Chapter 7 tables (see below) to know that glass ceramics and other fire-protection-rated glazing such as specialty tempered and wired products have specific size and application limitations. The reason being that fire-protection-rated glazing only blocks smoke and flames, and not radiant heat. This inability to block radiant heat is the reason why all fire-protection-rated glass products have the following imposed limitations:

- Overall sizes are limited to the maximum size tested not to exceed 25% of the wall area.

- For interior separations, 20-45 minute fire-protection-rated glazing is only permitted in one hour rated fire barriers for incidental use area or mixed occupancy separations, or in fire partitions.

- Sidelites and transoms in fire door assemblies are limited to a maximum of 45 minute rating.

- Exterior walls permit 20-90 minute fire-protection-rated glazing for fire windows depending on fire separation distance and occupancy type in section 705 of the 2012 IBC.

60 minute, 90 minute and 180 minute fire-protection-rated vision lites in fire doors are limited to 100 sq.in.

I have a problem with the unqualified statement ‘fire ratings up to 3 hours’, and you should too. While it is true that ceramics, a fire-protection-rated-product, are listed up to 3 hours, it is purposely misleading. What the advertisement doesn’t tell you – but should have, if code compliance is important to this advertiser – is that where 60/90/120/180 minute ratings are prescribed, the code limits the use of ceramics to 100. sq. inches in 60/90/180 minute doors, and ceramics cannot be used at all in 60/120 minute interior windows, sidelites and transoms regardless of whether sprinklers are employed or not.

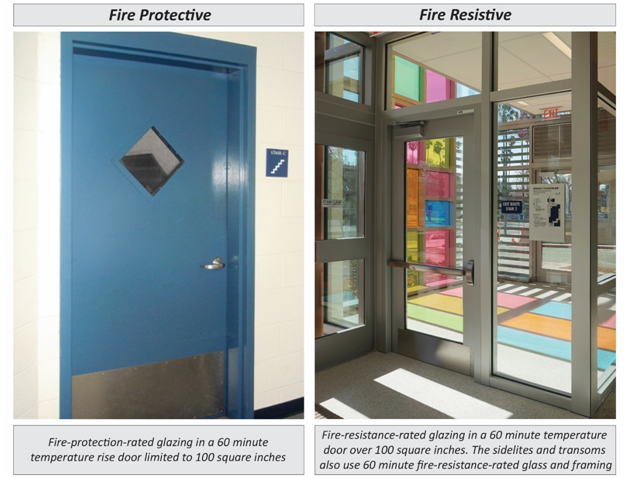

The good news is that fire-resistance-rated glazing does not have the size and application limitations that the IBC imposes on fire-protection-rated glazing. In addition to blocking smoke and flames, fire-resistance-rated glazing tested to ASTM E-119 also blocks the passage of radiant heat. Because of this, fire-resistance-rated glazing can be used up to the maximum size tested in all 60 to 120 minute applications. Here’s a side by side visual comparison of fire-protection-rated vs. fire-resistance-rated glazing used in a 1-hour stairwell application:

Part of the confusion is in the way fire rated glass products are asked to be tested by the manufacturer and then subsequently listed by the testing agencies. It is important for design professionals and code enforcement officials to understand that the listing agencies do not list fire rated glass products in accordance with the code or limitation on their use, but rather, by what the manufacturer requested to be tested. Test agencies simply report the sizes and types of assemblies in which a product was tested. For example, test agencies often list ceramic glazing products in 60 and 90 minute sidelite and transom assemblies. These are application ratings that are not permitted in opening protectives that require a specified 60 or 90 minute product under any building code in use in the United States. Thus, listings cannot be relied on for determining the glazing product’s acceptability for both size and code compliance. So when in doubt, refer to the IBC requirements – not a product’s listing or paid advertising – to ensure code compliance and the proper choice of a fire rated glazing product.

Hopefully, the understanding of this confusing issue starts a dialogue between fire rated glass suppliers, testing agencies and building officials. The fact is, ceramic is not a fire-resistance-rated glazing product under the code because it does not meet ASTM E-119. Every day, fire rated glazing providers like ourselves are asked to quote or provide materials that are not usable or that could be rejected in the field. This is happening because listings do not state the limitations to the listings given. As seen in the following chart, (based upon the 2012 and 2015 editions of the IBC), some of the tested sizes and applications given to ceramics are not code compliant per the IBC. It’s time to make it easier for designers, building officials and end-users to select the correct and code approved product for their application by having the limitations of the listings qualified in those listings.

Click here to download a chart showing where fire protective ceramic’s published listings conflict the 2012 & 2015 IBC code requirements.

Click here to download the IBC Chapter 7 Tables.

More from Author

Bill O'Keeffe | Oct 19, 2020

Going virtual

Manufacturers use virtual platforms to help architects meet CEU requirements.

Bill O'Keeffe | Jul 16, 2020

Obsolete?

"Revolutional, affordable, USA made Fire Rated Glazing for all fire protective areas makes ceramic glazing obsolete". Check out SuperClear 45-HS and SuperClear 45-HS-LI to understand why!

Bill O'Keeffe | Feb 10, 2020

USA-made fire rated glazing goes big in 2020

We are pleased to announce and share that the second phase of this $8 million expansion, upgrading our fire rated glass manufacturing facilities in Merced, California, is underway.

Bill O'Keeffe | Nov 20, 2019

Demand for advanced, USA-made fire rated glazing “RAISES THE ROOF”

With architects specifying full-vision, code-compliant, 60 and 90 minute, temperature rise doors for exit stairwells and other code required applications, we found this as an opportunity to expand our product offerings.