The industrial-style Tobey Building on the New Hampshire Hospital campus in Concord, NH, was renovated and is now considered to have one of the most state-of-the-art HVAC systems in the U.S.

SAM Mechanical Services, LLC, a commercial plumbing and HVAC company in New Hampshire, helped the facility and Lavalle Brensinger Architects design and install the new HVAC system.

This unique, green cooling system significantly reduces cooling costs. Power plants that serve New Hampshire must keep their output stable in order to provide needed electricity during peak daytime hours, but during off-peak hours overnight, the unused electricity goes to waste. As a result, local power plants provide special pricing during off-peak hours, which is metered separately. The off-peak ice storage production cooling system uses this reduced-rate electricity to its greatest advantage.

The system uses chillers to make and store ice in underground tanks overnight. During the day, when other buildings of comparable size have chiller systems running full bore, the Tobey Building is saving money by cooling with a recirculating water loop integrated into the underground ice tanks.

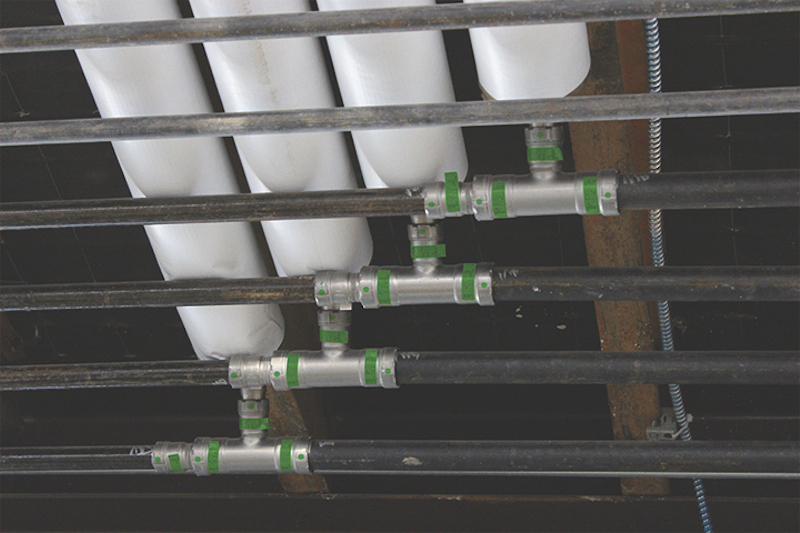

SAM Mechanical installed Viega MegaPress® fittings for the chilled water applications, an additional savings factor for the building. “We had several miles of pipe on each floor,” said Steve April, owner of SAM Mechanical. “It was a green design concept where everyone else’s bid went with geothermal.”

An efficient system all around, the time required to transition the Tobey Building into this unique system was critical, given the number of components that had to come together to make it happen and perform to required specifications.

“From our perspective, we were able to pipe it up in less time and overall less cost using Viega MegaPress fittings,” April said. “It cuts labor in so many ways and removes the sometimes frequent problem of threading and cutting equipment that’s not working properly. The Tobey job, which had thousands of fittings, saved at least 50% of piping installation time.”

Viega has the only press system for black iron pipe installations that covers hydronic applications with MegaPress and Viega MegaPressG for gas systems. With system-matched tools and jaws, press connections are made in less than seven seconds, making Viega MegaPress suitable for virtually any type of project. For the Tobey Building, where time and quality counted, SAM Mechanical trusted Viega to get the job done right the first time.

“I would encourage anyone considering using Viega MegaPress to do so,” April said. “At the end of the day, a big job can have a substantial savings especially in labor. As far as the Tobey Building, with that many fittings it was important to choose a product that wouldn’t leak, giving me peace of mind that I helped keep this historical building safe and secure for decades to come.”

Viega MegaPress used for chilled water in HVAC system

For more information, visit www.viega.us.

Viega

800.976.9819

insidesales@viega.us

Related Stories

| Apr 3, 2012

Blaine Brownell on innovative materials applications in architecture

Brownell, who was named a BD+C 40 Under 40 in 2006, provides insight regarding emerging material trends and the creative implementation of materials.

| Mar 12, 2012

Improving the performance of existing commercial buildings: the chemistry of sustainable construction

Retrofitting our existing commercial buildings is one of the key steps to overcoming the economic and environmental challenges we face.

| Mar 6, 2012

Joliet Junior College achieves LEED Gold

With construction managed by Gilbane Building Company, Joliet Junior College’s Facility Services Building combines high-performance technologies with sustainable materials to meet aggressive energy efficiency goals.

| Mar 1, 2012

Reconstruction of L.A.’s Dunbar Hotel underway

Withee Malcolm Architects’ designs for the project include the complete renovation of the Dunbar Hotel and the Somerville Apartments I and II.

| Feb 26, 2012

Milwaukee U-Haul facility receives LEED-CI Silver

The new elements of the facility now include: efficient lighting with day-lighting controls and occupancy sensors, a high-efficiency HVAC system used in conjunction with a newly constructed thermal envelope to help reduce energy consumption, and the installation of low-flow fixtures to reduce water consumption.