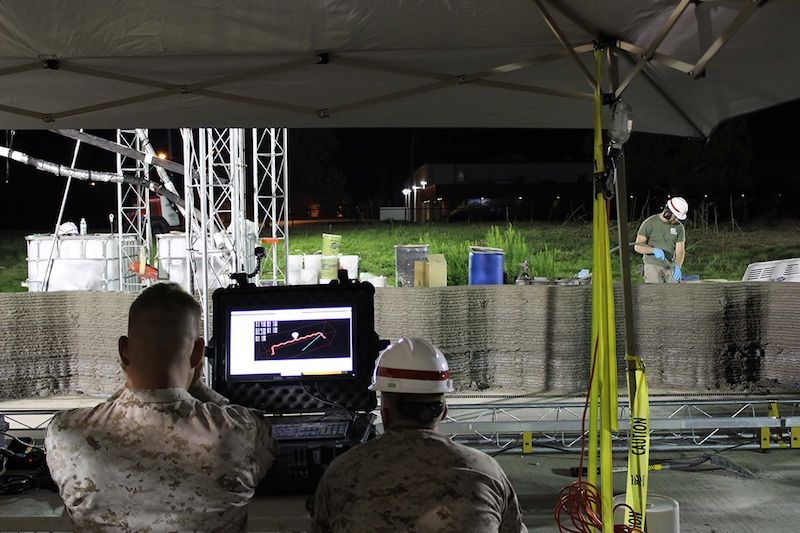

The Additive Manufacturing Team at Marine Corps Systems Command (MCSC) and Marines from I Marine Expeditionary Force recently teamed up at the U.S. Army Engineer Research and Development Center to 3D print a barracks.

The team used a computer-aided design model on a 10-year-old computer, concrete, and a 3D printer to create the 500-sf building. The job took 40 hours, but the Marines claim if there was a robot to do the mixing and pumping, the building could easily be created in one day. Typically, it takes 10 Marines five days to build a barracks out of wood.

See Also: Dubai plans to 3D print 25% of every new building by 2025

According to Capt. Matthew Friedell, AM project officer in MCSC’s Operations and Programs/G-3, nothing like this has been done before. “People have printed buildings and large structures, but they haven’t done it onsite and all at once. This is the first-in-the-world onsite, continuous concrete print,” Friedell said in a release.

Not only does using a concrete printer expedite barracks construction, but it can also help keep Marines safe. “In active or simulated combat environments, we don’t want Marines out there swinging hammers and holding plywood up. Having a concrete printer that can make buildings on demand is a huge advantage for Marines operating down range,” says Friedell.

The Marine Corps is currently staffing a deliberate urgent needs statement and concept of employment for this technology. The results of the field user evaluation will inform future requirements to give the Corps a concrete construction additive manufacturing program of record.

For more information, click here.

Related Stories

3D Printing | Apr 17, 2017

The Tokyo Pod Vending Machine resembles a giant game of Tetris in the sky

The building is designed to print and dispense its own dwellings in vending machine-obsessed Tokyo.

University Buildings | Oct 19, 2016

UC Merced to nearly double its size by 2020

Its growth strategy includes adding 1.2 million sf of space for teaching, housing, and research.

3D Printing | Jun 14, 2016

By 2021, 3D concrete printing is projected to be a $56.4 million industry

The 3D concrete printing industry is expected to more than double in size within the next five years.

3D Printing | May 26, 2016

Dubai opens world’s first 3D-printed office

The 2,690-sf structure took 17 days to print. City officials say the labor cost was only half as much as similar size conventional buildings.

3D Printing | Mar 29, 2016

Autodesk’s Project Escher prints large objects in fraction of the time

By networking 3D printers and divvying up the work, the project creates big items 80% to 90% more efficiently.

3D Printing | Feb 23, 2016

University of Tokyo students develop 3D-printing pen

The pen, which melts and strings together plastic filaments, can be used to make large-scale temporary structures.

3D Printing | Feb 11, 2016

Microscape mini 3D models give you the whole city in your hands

Starting with Manhattan, the company hopes to expand to other cities, villages, and "suburban cul-de-sacs" with its detailed, 3D models.

3D Printing | Jan 25, 2016

Architecture students create new method for 3D printing concrete

The team's Fossilized project allows for structures that are more varied and volumetric than other forms so far achieved.