Expansion is a concern on every project with large drywall runs. Expansion occurs for a variety of reasons, including humidity, temperature changes and building movement. Without the proper expansion product, cracking or drywall buckling can occur.

While Baker Triangle was building the Southwest Energy office building in Houston, they knew they would need expansion products due to the large building size and layout. In the Southwest Energy building, expansion joints were placed in the massive ceiling expanses. To accommodate the building design, Baker Triangle wanted to installed curved 093 expansion beads. In the past, the only option for curved expansion products were special order and especially expensive metal products. Facing a tight deadline, instead of waiting weeks for clunky metal 093 beads to arrive, Baker Triangle turned to Trim-Tex 093V Expansion. Trim-Tex 093V is manufactured from flexible vinyl and easily formed to match the curved ceiling reveal design in the Southwest Energy office building.

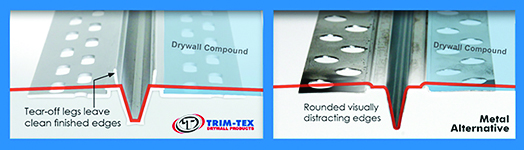

In addition to being flexible, Trim-Tex 093V features a full 3/8” in controlled movement, which is more than any other 093 product on the market. Once it is installed, architects and builders need not worry about expansion issues marring a beautiful structure. 093V also has tear off strips, allowing the the center expansion channel to remain mud free and the tear off helps create an overall sharper finished edge. Trim-Tex 093V is also designed to provide expansion control on either walls or ceilings, so regardless of the surface it can be protected from expansion problems. Like all Trim-Tex products, 093V never dents, rusts or acts as a source for mold growth, which reduces long-term building maintenance costs.

For more information, visit www.Trim-Tex.com

Related Stories

| Jun 13, 2017

Accelerate Live! talk: Next-gen materials for the built environment, Blaine Brownell, Transmaterial

Architect and materials guru Blaine Brownell reveals emerging trends and applications that are transforming the technological capacity, environmental performance, and design potential of architecture.

Sponsored | Building Materials | Jun 9, 2017

Problem solving in Asheville with R-Trac & ALPOLIC® materials

The developers of the recently opened Asheville City Center sought out a cost-effective design that met code requirements while still allowing the building to feel open from the outside.

Sustainability | May 16, 2017

1.5 million recycled plastic bottles were used to build this nine-story structure in Taipei

The building is made of Polli-Brick, a building material that comes from 100% recycled Polyethylene Terephthalate Polymer.

Building Technology | May 5, 2017

Tips for designing and building with bathroom pods

Advancements in building technology and ongoing concerns about labor shortages make prefabrication options such as bathrooms pods primed for an awakening.

Building Technology | Apr 21, 2017

AIA selects 2016 Upjohn Research Initiative Projects

Grants awarded to initiatives that study various aspects of design within the built environment.

Market Data | Mar 22, 2017

After a strong year, construction industry anxious about Washington’s proposed policy shifts

Impacts on labor and materials costs at issue, according to latest JLL report.

Sponsored | Building Materials | Mar 20, 2017

Vinyl reveals meet increasing demand

With a tight school renovation budget and timeline, the Oak Grove Elementary cafeteria, designed by RuckPate Architects/CS2 Designs, utilized Architectural Reveals to build curving soffits with a racing stripe reveal design.