Expansion is a concern on every project with large drywall runs. Expansion occurs for a variety of reasons, including humidity, temperature changes and building movement. Without the proper expansion product, cracking or drywall buckling can occur.

While Baker Triangle was building the Southwest Energy office building in Houston, they knew they would need expansion products due to the large building size and layout. In the Southwest Energy building, expansion joints were placed in the massive ceiling expanses. To accommodate the building design, Baker Triangle wanted to installed curved 093 expansion beads. In the past, the only option for curved expansion products were special order and especially expensive metal products. Facing a tight deadline, instead of waiting weeks for clunky metal 093 beads to arrive, Baker Triangle turned to Trim-Tex 093V Expansion. Trim-Tex 093V is manufactured from flexible vinyl and easily formed to match the curved ceiling reveal design in the Southwest Energy office building.

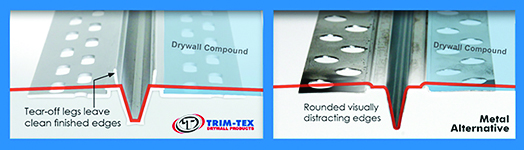

In addition to being flexible, Trim-Tex 093V features a full 3/8” in controlled movement, which is more than any other 093 product on the market. Once it is installed, architects and builders need not worry about expansion issues marring a beautiful structure. 093V also has tear off strips, allowing the the center expansion channel to remain mud free and the tear off helps create an overall sharper finished edge. Trim-Tex 093V is also designed to provide expansion control on either walls or ceilings, so regardless of the surface it can be protected from expansion problems. Like all Trim-Tex products, 093V never dents, rusts or acts as a source for mold growth, which reduces long-term building maintenance costs.

For more information, visit www.Trim-Tex.com

Related Stories

| Mar 21, 2014

Forget wood skyscrapers - Check out these stunning bamboo high-rise concepts [slideshow]

The Singapore Bamboo Skyscraper competition invited design teams to explore the possibilities of using bamboo as the dominant material in a high-rise project for the Singapore skyline.

| Mar 20, 2014

Common EIFS failures, and how to prevent them

Poor workmanship, impact damage, building movement, and incompatible or unsound substrate are among the major culprits of EIFS problems.

| Mar 20, 2014

13 dazzling wood building designs [slideshow]

From bold structural glulam designs to striking textured wall and ceiling schemes, these award-winning building projects showcase the design possibilities using wood.

| Mar 19, 2014

Federal agency gives thumbs up to tall wood buildings

USDA's support for wood projects includes training for AEC professionals and a wood high-rise design competition, to launch later this year.

| Mar 17, 2014

Rem Koolhaas explains China's plans for its 'ghost cities'

China's goal, according to Koolhaas, is to de-incentivize migration into already overcrowded cities.

| Mar 12, 2014

14 new ideas for doors and door hardware

From a high-tech classroom lockdown system to an impact-resistant wide-stile door line, BD+C editors present a collection of door and door hardware innovations.

| Mar 10, 2014

Meet Tally – the Revit app that calculates the environmental impact of building materials

Tally provides AEC professionals with insight into how materials-related decisions made during design influence a building’s overall ecological footprint.

| Mar 5, 2014

5 tile design trends for 2014

Beveled, geometric, and high-tech patterns are among the hot ceramic tile trends, say tile design experts.

| Mar 4, 2014

How EIFS came to America

Design experts from Hoffmann Architects offer a brief history of exterior insulation and finish systems in the U.S.

| Feb 27, 2014

12 facts about heat-treated glass: Why stronger isn’t always better

Glass is heat-treated for two reasons: the first is to increase its strength to resist external stresses such as wind and snow loads, or thermal loads caused by the sun’s energy. The second is to temper glass so that it meets safety glazing requirements defined by applicable codes or federal standards.