A growing number of firms, including HDR, NBBJ, and Thornton Tomasetti, are investing in talent and training to advance their computational design capabilities. Here’s a roundup of the clever applications for CD:

1. Rapid prototyping. Why design a few prototypes when you can create thousands to find the ideal solution? Algorithm-based design processes allow teams to develop and explore dozens, even hundreds, of prototypes in a matter of hours—something that would be impossible using traditional methods.

2. Rapid iteration. Similarly, computational design is being used to more efficiently test and refine particular design schemes through rapid iteration—design, test, refine, repeat, in quick succession.

3. Data dashboards. Data can be an incredibly helpful resource for Building Teams, especially if it’s readily accessible and real time. Progressive firms are using CD methods to extract vital data from, for example, BIM models to feed custom Excel dashboards. Other firms are investing in more scalable platforms, such as Web-based data visualization, to gain insight into their data.

4. Automating repetitive duties. From mundane tasks like renaming files to complex projects like calculating the walking steps in a hospital floor plan, computational design tools can be used to automate the grunt work in the design process.

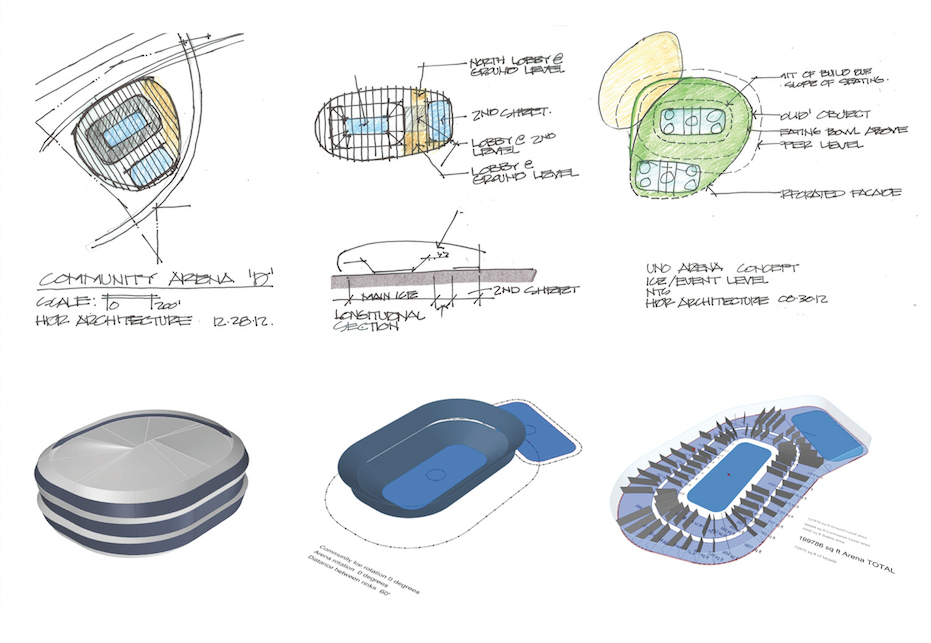

Using computational design tools, a team at HDR created an iterative process for building on-the-fly parametric models directly from sketches.

Using computational design tools, a team at HDR created an iterative process for building on-the-fly parametric models directly from sketches.

5. Creating custom plug-ins for existing software platforms. Need a tool that doesn’t exist on the market? No problem. Just code a solution. An extreme example is Thornton Tomasetti’s TTX database, which provides real-time read, write, and sync capabilities across six software tools: ETABS, Grasshopper, RAM Structural System, Revit, SAP 2000, and Tekla.

6. Evaluating the performance of early design concepts. Energy analysis, daylight modeling, even cost and schedule impacts—CD tools allow teams to make informed decisions much earlier in the design process.

For more on computational design, see BD+C's feature story, “Conquer computational design: 5 tips for starting your journey.”

Related Stories

| Jul 11, 2014

Are these LEGO-like blocks the future of construction?

Kite Bricks proposes a more efficient way of building with its newly developed Smart Bricks system.

| Jul 1, 2014

Hyper-speed rendering: How Gensler turns BIM models into beauty shots in seconds

In search of a fast rendering solution, Gensler looked to the gaming and moviemaking industries for the next breakthrough tool: Octane Render.

| Jul 1, 2014

Sochi's 'kinetic façade' may steal the show at the Winter Olympics

The temporary pavilion for Russian telecom operator MegaFon will be wrapped with a massive digital "pin screen" that will morph into the shape of any face.

| Jul 1, 2014

7 ways to cut waste in BIM implementation

Process mapping, split models, and streamlined coordination meetings are among the timesaving techniques AEC firms are employing to improve BIM/VDC workflows.

| Jun 30, 2014

Autodesk acquires design studio The Living, will create Autodesk Studio

The Living, David Benjamin's design studio, has been acquired by Autodesk. Combined, the two will create the Autodesk Studio, which will "create new types of buildings, public installations, prototypes and architectural environments."

| Jun 30, 2014

Report recommends making infrastructure upgrades a cabinet-level priority

The ASCE estimates that $3.6 trillion must be invested by 2020 to make critically needed upgrades and expansions of national infrastructure—and avoid trillions of dollars in lost business sales, exports, disposable income, and GDP.

| Jun 25, 2014

Taking a page from Lean manufacturing for improved design review processes

SPONSORED CONTENT As more building project teams look for ways to collaborate better, technology continues to provide solutions. Yet, as I learned from the experience of one of my customers, choosing the wrong technology can have an underwhelming effect, causing a team to simply swap out old challenges for new ones.

| Jun 18, 2014

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 10, 2014

Site optimization: Paving the way for smoother land development projects

The biggest cost differential when dealing in site development from one site to another is the earthwork. So, when selecting a site, it is critical to not only take into account the initial purchase price of the property, but also what sort of investment it will take to prep the site for development.

Smart Buildings | Jun 8, 2014

Big Data: How one city took control of its facility assets with data

Over the past few years, Buffalo has developed a cutting-edge facility management program to ensure it's utilizing its facilities and operations as efficiently, effectively, and sustainably as possible.