In early 2008, as a storm approached northern Michigan, a 19-year-old construction worker raced to the rooftop of a multifamily building to clear the area of construction debris. Unaware that a metal roof curb—which was not secured or labeled—was covering a make-up air shaft, the worker tried to move the curb onto a stack of plywood. He fell through the roof opening 69 feet to his death.

In late 2009, in Washington state, a 45-year-old carpet installer was unloading 12-foot-long carpet rolls from a skip box through a window onto the fourth floor of a hotel project. With one foot on the window sill and the other on a roll of carpet protruding from the skip box, the laborer, who was not wearing fall protection, slipped and fell 32 feet to the concrete sidewalk below, causing fatal injuries.

5 WAYS TO USE BIM/VDC COORDINATION TO PROMOTE SAFETY

1. Prefabrication—Moving work to a warehouse environment greatly reduces the risk of slips, trips, falls, and soft-tissue injuries.

2. Safety hazards analysis—Firms are using software tools to quickly scan BIM models for problem areas, such as floor and roof penetrations, and coordinate necessary safety provisions.

3. Site coordination—Advanced construction sequencing and dimensional analysis allow firms to better track and manage site logistics and layout.

4. Facilities O&M planning—With the BIM model serving as a virtual mockup, firms can work with facilities teams to optimize spaces for faster, safer maintenance tasks.

5. Day-to-day safety coordination—Safety managers can access the BIM model on the job site, helping to improve inspections and validate that safety provisions are being met.

Cases like these are all too common in the U.S. construction industry. Each year, the industry claims roughly 815 lives and accounts for more than 200,000 nonfatal injuries and illnesses, according to the Bureau of Labor Statistics.

A small but growing number of BIM/VDC and safety experts assert that the primary causes of job site injuries and fatalities—falls from roofs, ladders, and scaffolds; soft-tissue injuries from material handling; burns from hot work, such as welding—could be greatly minimized with advanced planning and coordination using BIM tools. The technology, they say, helps with preconstruction risk assessment of building projects and the day-to-day implementation of safety provisions on the job site. It also enables teams to utilize offsite prefabrication, preassembly, and other so-called “prevention through design” approaches.

“BIM-enabled prefabrication has allowed us to eliminate tens of thousands of excursions up ladders and lifts, and thousands of hours of hot work and general construction activities in ergonomically difficult situations,” says Tony O’Dea, Gilbane’s Director of Corporate Safety. “The most expensive source of worker’s comp is soft-tissue injuries, primarily related to material handling. Prefab gets trades off the site and into a safer, more ergonomic environment. It also gets materials and large equipment, such as scissor lifts, off the site.”

ASSIGNING OWNERSHIP OF JOB SITE SAFETY PROVISIONS

As part of its Preconstruction Safety Alignment and Risk Assessment program, Gilbane’s project teams, along with its Interdisciplinary Document Control Department, review project models to identify potential risks. Most teams also take part in a Lean strategy kickoff session, where opportunities for prevention through design, such as the use of prefab, are evaluated.

“After that, we make assignments of responsibility within the subcontractor agreements that will enforce our safety plan for the project,” says O’Dea.

Responsibility and enforcement are two of the biggest gaps in safety on construction sites, says John Tocci, Sr., CEO of Tocci Building Companies. His firm uses BIM model analysis to track obvious safety provisions like site conditions, perimeter protection elements, and hundreds of site exposures that “open up and close” during the course of a project, such as floor penetrations for elevator shafts and ductwork.

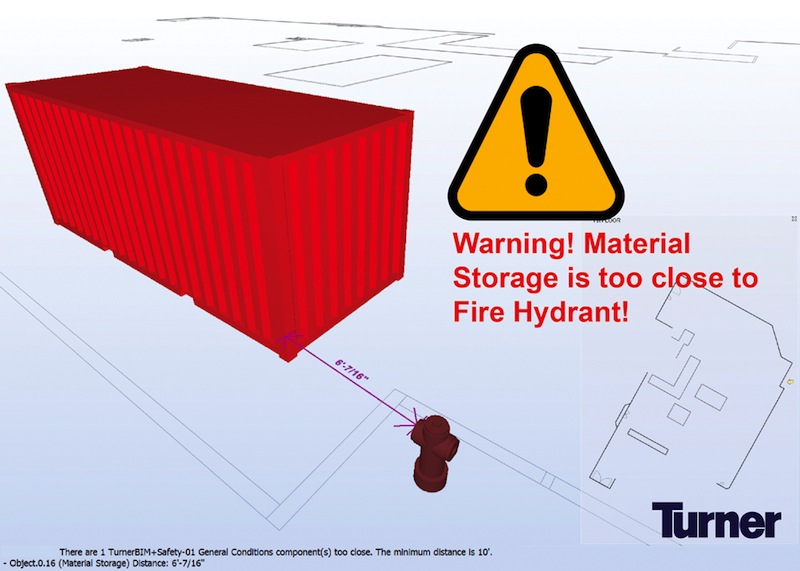

Turner Construction uses Solibri Model Checker software to write and apply custom rule sets to search for safety-related problem areas in BIM models, such as the location of fire extinguishers and material storage areas. Rendering: Turner Construction

Turner Construction uses Solibri Model Checker software to write and apply custom rule sets to search for safety-related problem areas in BIM models, such as the location of fire extinguishers and material storage areas. Rendering: Turner Construction

Tocci says that one reason it’s difficult to get an exposure protected is that there are disagreements that occur on the job site as to whose responsibility it is to provide the safety protection. BIM, he says, takes the guesswork and unknowns out of the equation. It allows project teams to perform day-to-day—even hour-to-hour—sequencing of projects to more accurately define temporary site exposures, including the window of time when each becomes a safety risk. Tocci’s project teams also use BIM to quantify the materials required to protect the area.

“When you define all of these parts and pieces, like floor opening coverings and fall protection provisions, they can be used in the purchasing and prequalification of major subcontractors and trade partners,” says Tocci. “People are prepared on a specific day with 30 sheets of three-quarter-inch plywood to cover 15 floor penetrations. There’s no arguing about who is responsible for executing the work. It just gets done.”

ADVANCED SAFETY MODEL CHECKING

Project teams using Turner Construction’s BIM-based safety checking initiative, which was launched in 2010, scan BIM models for 137 safety-related provisions across site conditions, excavation, substructure, and superstructure. The construction giant uses Solibri Model Checker software to write and apply custom rule sets to search for problem areas in BIM models.

“We’re validating items based on dimensional and informational relationships, such as the location and separation distance between fire extinguishers, the number of units per square feet of space, and the distance from hoists and egress stairs,” says Jennifer Downey, Turner’s National BIM Manager for Integrated Building Solutions. Downey offers other common safety check areas:

- Material storage locations, and their proximity to fire hydrants and adjacent structures

- Design criteria for the ramps on the site, including slope, landing distances at the top and bottom, and entrance and exit locations

- Location, size, and timeline of temporary job site hazards—floor penetrations, perimeter protection areas, etc.—and the materials required for protection

- Requirements for erosion and sedimentation control

- Equipment and egress requirements by phase

- Pedestrian protection measures

Once a project model is scanned and problem areas are identified, a safety analyst reviews the findings and produces colorful graphic reports that can be viewed directly in the BIM model or in an Excel-based report.

“With graphics-based reporting, there’s something really simple and tangible about seeing openings that don’t have edge protection or materials that are stored too close to a fire hydrant,” says Downey. “Each element is itemized so it can be reviewed quickly and checked off.”

Turner’s site safety modeling and checking program is just one piece in a broader strategy of using BIM to more comprehensively preplan safety and logistics tasks. Turner engineers leverage a variety of modeling and analysis tools—from Trimble SketchUp to Autodesk Revit to mobile apps—to mitigate risk and communicate more clearly with the entire project team.

PREVENTION THROUGH DESIGN

Specialty contractor Southland Industries is taking BIM-driven safety planning a step further by incorporating provisions and design features aimed at protecting the facilities operations and maintenance team. The company regularly incorporates “exclusion zones” in its project models to virtually block off areas that require regular maintenance. Southland’s engineers also optimize the design and layout of service aisles and interstitial spaces to eliminate potential hazards and simplify maintenance, says Joe Visgaitis, Southland’s Mid-Atlantic Division Safety Manager.

With the typical interstitial area, says Visgaitis, utilities crisscross through the space, forcing maintenance staff to climb over and duck under pipework and avoid hot pipes. “On a recent project, I told our team that I would like to be able to walk freely down the service aisle with a 32-inch-wide cart, and have key service areas within an arm’s reach of the main aisle,” he says.

SAFETY BUILT IN

Tocci says the next step in his company’s execution of BIM is to utilize the tool to eliminate falsework construction. “If you can avoid putting up scaffolding or staging on a project, you can save tens of thousands of dollars,” says Tocci. “It’s pure waste.”

The contractor recently worked on a reclad project that involved installing a glass curtain wall over an existing precast wall, with interstitial space and steel walkways in between. In the steel fabrication provisions, the firm included conditions to provide safety rails, safety cable, and safety catwalks right in the steel. “As the steel went up, the safety provisions went up with it,” says Tocci.

Related Stories

| May 24, 2017

Accelerate Live! talk: Applying machine learning to building design, Daniel Davis, WeWork

Daniel Davis offers a glimpse into the world at WeWork, and how his team is rethinking workplace design with the help of machine learning tools.

| May 24, 2017

Accelerate Live! talk: Learning from Silicon Valley - Using SaaS to automate AEC, Sean Parham, Aditazz

Sean Parham shares how Aditazz is shaking up the traditional design and construction approaches by applying lessons from the tech world.

| May 24, 2017

Accelerate Live! talk: The data-driven future for AEC, Nathan Miller, Proving Ground

In this 15-minute talk at BD+C’s Accelerate Live! (May 11, 2017, Chicago), Nathan Miller presents his vision of a data-driven future for the business of design.

Big Data | May 24, 2017

Data literacy: Your data-driven advantage starts with your people

All too often, the narrative of what it takes to be ‘data-driven’ focuses on methods for collecting, synthesizing, and visualizing data.

AEC Tech | May 23, 2017

A funny thing may happen on the way to AI

As AI proves safe, big business will want to reduce overhead.

Building Technology | May 5, 2017

Tips for designing and building with bathroom pods

Advancements in building technology and ongoing concerns about labor shortages make prefabrication options such as bathrooms pods primed for an awakening.

BIM and Information Technology | Apr 24, 2017

Reconciling design energy models with real world results

Clark Nexsen’s Brian Turner explores the benefits and challenges of energy modeling and discusses how design firms can implement standards for the highest possible accuracy.

BIM and Information Technology | Apr 17, 2017

BIM: What do owners want?

Now more than ever, owners are becoming extremely focused on leveraging BIM to deliver their projects.

Sustainable Design and Construction | Apr 5, 2017

A new app brings precision to designing a building for higher performance

PlanIt Impact's sustainability scoring is based on myriad government and research data.

BIM and Information Technology | Mar 28, 2017

Digital tools accelerated the design and renovation of one contractor’s new office building

One shortcut: sending shop drawings created from laser scans directly to a wood panel fabricator.