The buckling restrained braced frame system was introduced to the U.S. construction market in 1999 as a solution for meeting hardened building codes following the 1994 Northridge earthquake. Since then, BRBF has been used to stabilize hundreds of buildings along the West Coast, especially in earthquake-prone California.

As seismic codes play a larger role in building projects east of the Sierras, Building Teams across the country are turning to seismic design solutions like BRBF that were perfected in the West to meet increasingly stringent code requirements.

The latest example is the five-story, 179,000-sf Adult Behavioral Health Center, recently completed as part of the Dormitory Authority of the State of New York’s rebuilding of the Bronx Psychiatric Center campus, on behalf of the New York State Office of Mental Health.

Unlike many large-scale New York City structures built on solid rock foundations, the 156-bed Bronx healthcare facility is situated on wetlands that had been filled in with four million cubic yards of material generated from the construction of the Cross Bronx Expressway from 1948 to 1972. The poor soil conditions resulted in a Site Class F categorization and a Seismic Design Category D for the site. It called for an expanded geotechnical investigation and assessment, as well as seismic mitigation measures that were recently implemented under the New York State Building Code.

Situated on wetlands, the five-story, 179,000-sf Adult Behavioral Health Center in the Bronx, N.Y., required special seismic mitigation measures. Buckling restrained braces were the most economical, efficient solution.

Situated on wetlands, the five-story, 179,000-sf Adult Behavioral Health Center in the Bronx, N.Y., required special seismic mitigation measures. Buckling restrained braces were the most economical, efficient solution.

The structural design team, led by STV, first considered a traditional concentric braced frame lateral system. The solution met seismic requirements, but posed space-planning concerns for the client. Its relatively sizable structural elements and supporting walls would have bumped up against the health center’s programmatic requirements for rooms and circulation and would have jeopardized the architect’s open, airy indoor design scheme.

The final design approach, developed in conjunction with engineers in STV’s Los Angeles office, called for a BRBF system—a first for the Northeast—to enhance the structural performance of the building and greatly reduce steel frame member sizes. It also minimized the number of supporting walls needed for the project, and saved approximately $500,000 in material costs, according to Chris Cerino, PE, SECB, VP and Director of Structural Engineering, Building & Facilities Division, with STV. The firm also served as the design architect and electrical, civil, geotechnical, and telecom engineer on the project.

With the BRBF approach, certain braced frame steel columns could be downsized from W14x426 to W14x342, and select braced frame steel beams were reduced from W36x150 to W24x68.

“Smaller frame members gave STV designers flexibility in considering the movement of staff, residents, and food and building services,” says Cerino. “It also improved sightlines in all staff and resident areas to reduce the dependency on electronic monitoring.”

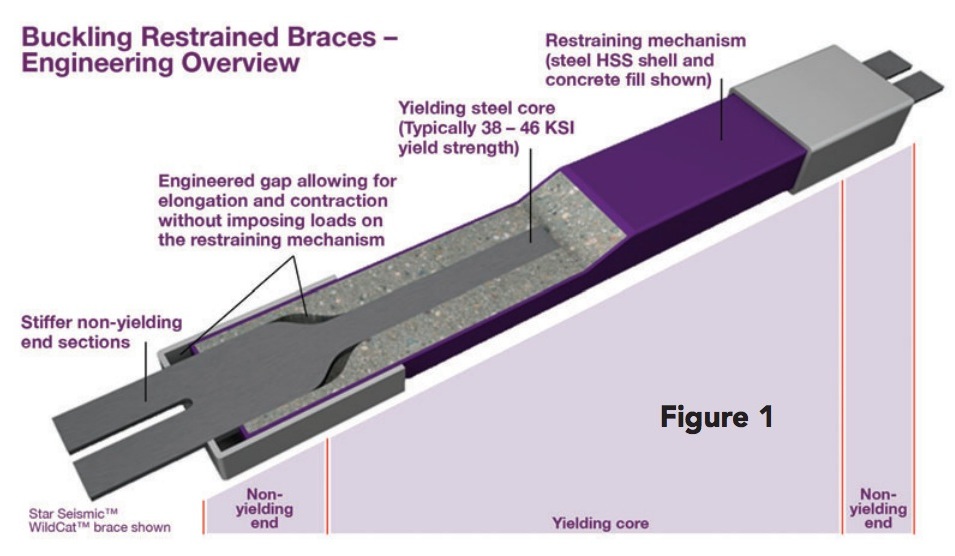

Buckling restrained braces (BRBs) vary slightly based on the manufacturer, but all BRBs include five basic components: a steel-plate core shaped like a kayak paddle (1) is placed within a hollow steel tube (2) that is coated with a low-friction material (3), which is then grouted in place (4) and capped (5). The grouted steel tube design prevents the steel core from buckling when in compression, while the coating prevents axial load from being transferred to the encasement.

The result is a “full, balanced response in relation to the forces being applied,” says Cerino. “Because the steel core is restrained, it develops nearly uniform axial strains across the section, resulting in efficient energy dissipation.”

This balanced energy dissipation, in turn, permits design teams to use much smaller beam sizes than with a standard braced frame.

On the Adult Behavioral Health Center project, Cerino’s team specified a proprietary system manufactured by Star Seismic. According to Cerino, Star’s Wildcat BRB system, which features single-pin connections, reduced erection time because it eliminated the need for stiffener plates. “Its patented collar reduces welding, since simple fillets can be used,” says Cerino. “That factored into the overall monetary savings.”

Cerino offers a few tips for Building Teams evaluating BRBFs:

- Watch out for the added special seismic requirements and details that become triggered when using a high-performance seismic system. “Not that a BRBF has different triggers than a special concentrically braced frame system, but since much of the design is deferred to the specialty brace contractor, some of the details can become out of sight, out of mind,” he says.

- Decide on the system early so you can address any client/procurement obstacles. “If it becomes too late, it can simply be easier to do nothing,” says Cerino. “That doesn’t help the project.”

Buckling restrained braces include several basic components: a steel-plate core is placed within a hollow steel tube that is coated with a low-friction material and then grouted in place and capped. The grouted steel tube design prevents the steel core from buckling when in compression, while the coating prevents axial load from being transferred to the encasement.

Buckling restrained braces include several basic components: a steel-plate core is placed within a hollow steel tube that is coated with a low-friction material and then grouted in place and capped. The grouted steel tube design prevents the steel core from buckling when in compression, while the coating prevents axial load from being transferred to the encasement.

Related Stories

Building Tech | Sep 6, 2018

19 decommissioned shipping containers become downtown Phoenix’s hottest marketplace

September 1 marked the opening of downtown Phoenix’s newest restaurant and retail marketplace—and its latest commercial construction project to utilize decommissioned shipping containers as its primarily building form.

Modular Building | Jul 23, 2018

Offsite construction: Why it’s important for the survival of your firm

The industry is approaching its “heart attack moment,” with so many large projects that are chronically late, over budget, and unprofitable, writes FMI Capital Advisors’ Michael Swistun.

Accelerate Live! | Jun 24, 2018

Watch all 19 Accelerate Live! talks on demand

BD+C’s second annual Accelerate Live! AEC innovation conference (May 10, 2018, Chicago) featured talks on AI for construction scheduling, regenerative design, the micro-buildings movement, post-occupancy evaluation, predictive visual data analytics, digital fabrication, and more. Take in all 19 talks on demand.

| Jun 11, 2018

Accelerate Live! talk: The smart jobsite — Predictive visual data analytics for proactive project controls

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), a trio of experts in predictive visual data analytics presents how design-build giant Clayco has leveraged this technology to achieve production efficiency on several construction sites.

| Jun 11, 2018

Accelerate Live! talk: Design innovation at Adrian Smith + Gordon Gill Architecture

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), AS+GG’s Anthony Viola takes us behind the magic curtain to illuminate the firm’s methods for nurturing design innovation.

| Jun 11, 2018

Accelerate Live! talk: ‘AEC can has Blockchains?’

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), HOK’s Greg Schleusner explores how the AEC industry could adapt the best ideas from other industries (banking, manufacturing, tech) to modernize inefficient design and construction processes.

| Jun 11, 2018

Accelerate Live! talk: How advanced digital fabrication techniques are driving design innovation

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), SOM’s Lucas Tryggestad and Kyle Vansice present the firm’s 3D-printed building project and explore how digital fabrication is pushing design innovation.

| May 30, 2018

Accelerate Live! talk: Seven technologies that restore glory to the master builder

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), AEC technophile Rohit Arora outlines emerging innovations that are poised to transform how we design and build structures in the near future.

| May 30, 2018

Accelerate Live! talk: Why the AEC industry must adapt to the Internet of Things boom

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), building systems expert Jeff Carpenter explores established and emerging IoT applications for commercial and institutional buildings, and offers a technology roadmap for navigating the IoT landscape.

Building Technology | Mar 1, 2018

Small construction businesses will continue to lag other sectors in tech spending this year

A survey of 800 companies found tepid interest overall in investing in “big data.”