Clayco’s CEO and Chairman Bob Clark sees innovation as being at the center of what his firm does. It was one of the first GCs to use full-room computers, an IBM 3600 “that looked like a giant refrigerator,” he recalls. It was an early adopter of spreadsheet technology, using Prolog’s project management software.

In 2005, it started a full-service concrete subcontracting business that now has 1,000 employees and produces four million sf of concrete walls per year. Clayco was the first construction company to receive an FAA license to fly small unmanned aerial vehicles. In 2015, it launched Uplift Data Partners, a turnkey construction and real estate inspection service that uses drones. (It sold that business to PrecisionHawk.)

Clayco’s interest in drones led it to start Treehouse Adventures, a venture-capital entity that focuses on construction. Its investments include Ventana, a high-performance curtain wall fabricator and installer; and Drawn, a design group.

In 1993, Clayco formed its Mission Control team to bring project management out into the field. Mission Control started with a dozen people and now has one team member for every three project managers in the field. And the company’s “paradigm shift toward greater jobsite safety,” says Clark, got it involved recently in hard hat design with the Savannah (Ga.) College of Arts and Design.

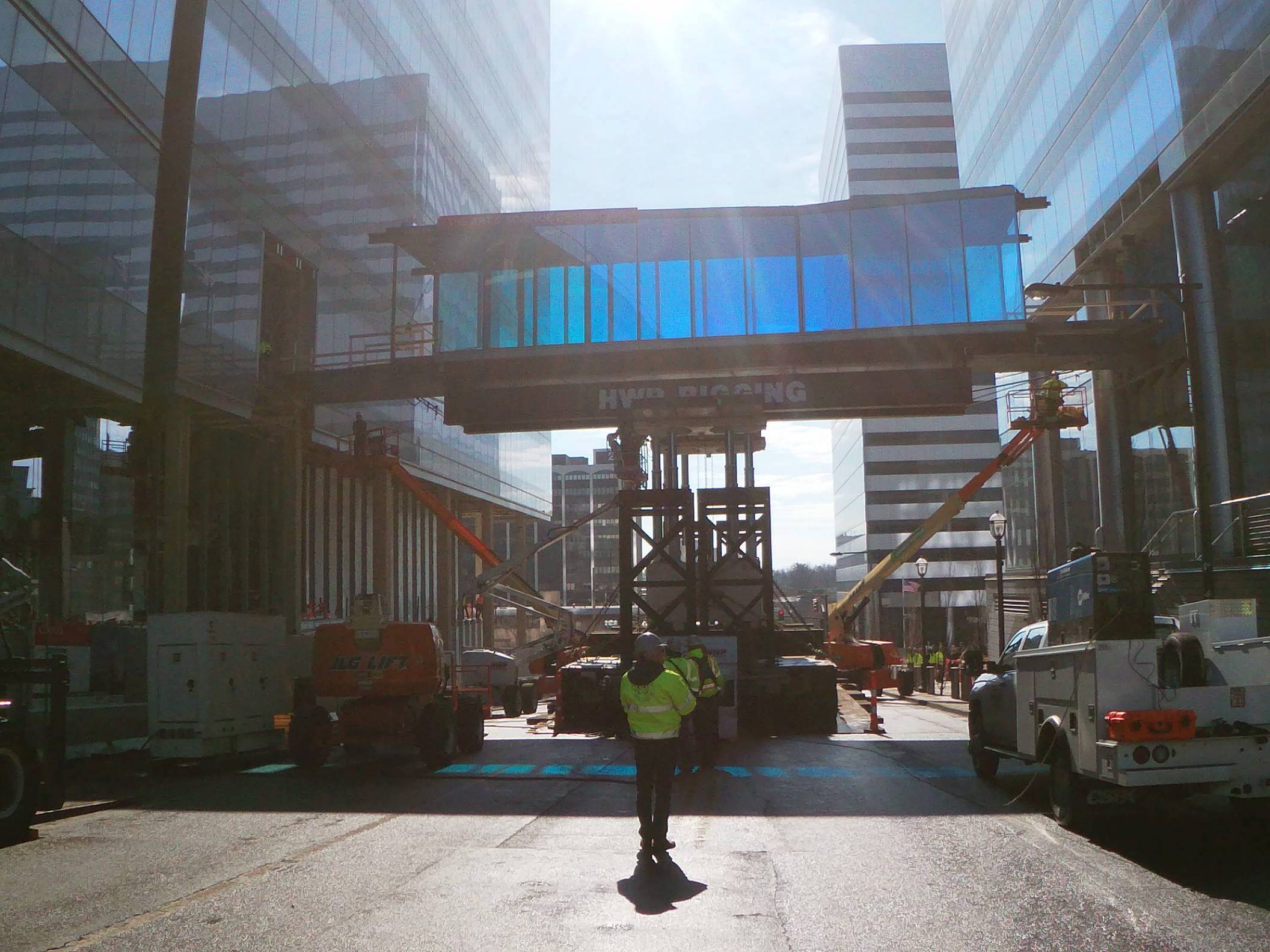

Its embrace of prefabrication allowed Clayco to build a bridge across a street in Missouri in a single day. Photo courtesy Clayco

Its embrace of prefabrication allowed Clayco to build a bridge across a street in Missouri in a single day. Photo courtesy Clayco

In June, the company combined its design businesses, Lamar Johnson Collaborative and BatesForum, providing Clayco with an integrated delivery model that Clark believes will “set a new standard.” Clark is looking ahead to see where else technology and better project management might give Clayco an edge.

He believes that modular construction will be required “on a mass scale” to counteract the industry’s aging workforce. Within three to seven years he expects robots to be doing more installation work.

ALSO SEE: Oracle’s replica of a construction jobsite creates an immersive environment for AEC professionals

Clark is a big proponent of BIM modeling and prefabrication. Last October, Clayco installed a bridge across a street in Clayton, Mo., in a single day by constructing the bridge’s steel-and-concrete components offsite. That delivery method saved local residents and businesses five months of impact on traffic.

For Pfizer’s 294,000-sf facility in Chesterfield, Mo., Clayco prefabricated the equivalent of two miles of lab walls, with conduit and pipe embedded.

Clark is also excited about artificial intelligence, albeit from a unique perspective of talent management to help employees map their careers and retirements. “We’re looking to build a talent management organization faster.”

For Pfizer’s 294,000-sf facility in Chesterfield, Mo., Clayco prefabricated the equivalent of two miles of lab walls, with conduit and pipe embedded. Photo courtesy Clayco

For Pfizer’s 294,000-sf facility in Chesterfield, Mo., Clayco prefabricated the equivalent of two miles of lab walls, with conduit and pipe embedded. Photo courtesy Clayco

Related Stories

Contractors | May 26, 2023

Enhanced use of data is crucial for improving construction job site safety

Executives with major construction companies say new digital tools are allowing them to use data more effectively to reduce serious safety incidents and improve job site safety.

AEC Tech Innovation | May 12, 2023

Meet Diverge, Hensel Phelps' new ConTech investment company

Thai Nguyen, Director of Innovation with Hensel Phelps, discusses the construction giant's new startup investment platform, Diverge.

Sustainability | May 1, 2023

Increased focus on sustainability is good for business and attracting employees

A recent study, 2023 State of Design & Make by software developer Autodesk, contains some interesting takeaways for the design and construction industry. Respondents to a survey of industry leaders from the architecture, engineering, construction, product design, manufacturing, and entertainment spheres strongly support the idea that improving their organization’s sustainability practices is good for business.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

AEC Tech Innovation | Apr 27, 2023

Does your firm use ChatGPT?

Is your firm having success utilizing ChatGPT (or other AI chat tools) on your building projects or as part of your business operations? If so, we want to hear from you.

Design Innovation Report | Apr 19, 2023

Reinforced concrete walls and fins stiffen and shade the National Bank of Kuwait skyscraper

When the National Bank of Kuwait first conceived its new headquarters more than a decade ago, it wanted to make a statement about passive design with a soaring tower that could withstand the extreme heat of Kuwait City, the country’s desert capital.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

Design Innovation Report | Apr 19, 2023

Meet The Hithe: A demountable building for transient startups

The Hithe, near London, is designed to be demountable and reusable. The 2,153-sf building provides 12 units of business incubator workspace for startups.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.

Smart Buildings | Apr 7, 2023

Carnegie Mellon University's research on advanced building sensors provokes heated controversy

A research project to test next-generation building sensors at Carnegie Mellon University provoked intense debate over the privacy implications of widespread deployment of the devices in a new 90,000-sf building. The light-switch-size devices, capable of measuring 12 types of data including motion and sound, were mounted in more than 300 locations throughout the building.