There probably isn’t a contractor in this country that at some point hasn’t been a victim of jobsite theft. In 2014, there were 11,625 heavy-equipment thefts reported to law enforcement, up 1.2% from 2013, according to the latest data from the National Insurance Crime Bureau in a report coproduced by the National Crime Information Center.

Total construction equipment theft now stands at around $1 billion annually. And only 23% of the heavy equipment stolen last year was recovered, the NICB report stated.

A survey conducted last year by Cygnus Business Media Research on behalf of LoJack, which makes theft-detection and –prevention devices, found that 83% of construction equipment owners polled had experienced equipment theft.

Courtney DeMilio, LoJack’s National Vice President of Commercial and Fleet, points out that theft can have a greater, negative impact on a business. “Loss in job productivity, the inability to complete a job, a diminished professional reputation—all while the owner is spending a substantial amount of time and money to replace the equipment,” she says.

The Canton, Mass.-based LoJack recently released its annual “Construction Equipment Theft and Recovery in the United States” report, based on its tracking, from January through December 2014, of theft reports in 28 states where equipment theft was reported and where construction equipment outfitted with a LoJack device led police to recover the stolen assets.

Graphics courtesy LoJack

Graphics courtesy LoJack

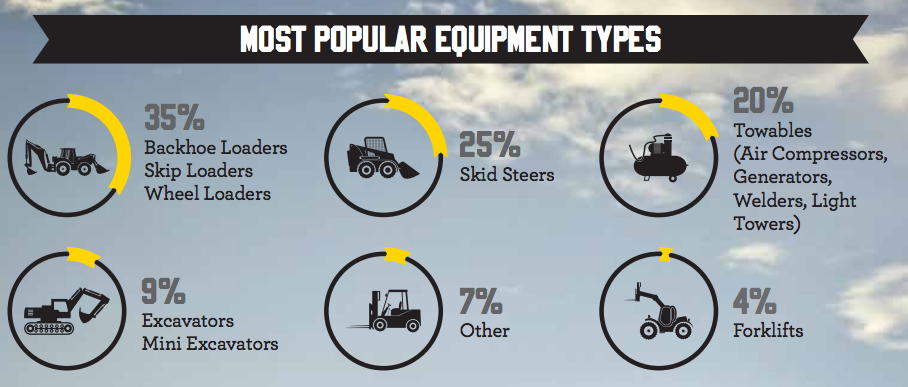

From that sample, the report identifies backhoe loaders, skip loaders and wheel loaders as the most popular equipment targeted by thieves. “There is little visual differentiation from one backhoe to another, and they all share a common key,” the report explains. “Therefore, they are prime targets for thieves based on the ease of theft and how hard they are to track once one is stolen.”

Skid steers, generators/air compressors/welders and portable light towers; and excavators are also most susceptible to robbery.

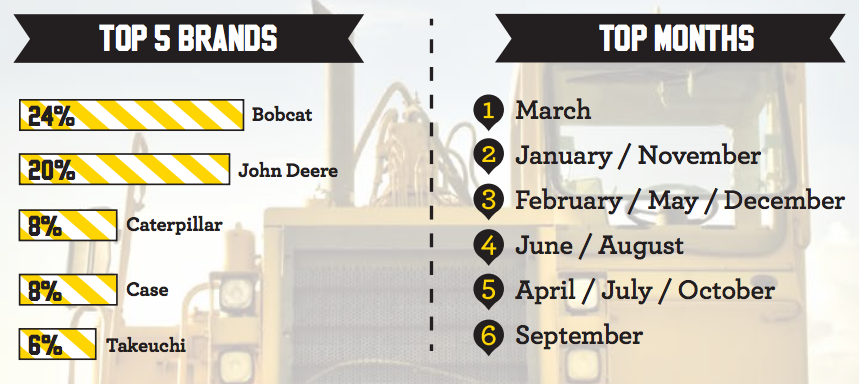

The report notes that thieves typically go after newer and brand-name equipment. In 2014, 54% of the tracked equipment stolen was less than five years old. And 65% of the thefts were of products made by top manufacturers such as Bobcat (24% of the equipment stolen), John Deere (20%), Caterpiller and Case (tied at 8% each), Takeuchi (6%) and Magnum (5%).

The report gives several reasons why construction equipment and tools continue to be vulnerable to thieves. For one thing, titling and registration of equipment aren’t mandated, so it’s often hard to report theft and harder for law enforcement to track what’s stolen. There’s also no standardized identification numbers on this stuff, like the Vehicle Identification Numbers on cars and trucks.

In addition, jobsite security is not always as tight as it could be, and the sites themselves can be remote. And because equipment and tools are constantly being transferred between sites, owners can be lax in their inventory accounting.

“The thief isn’t always somebody unrelated to the job, as often he or she can be a member of the company that owns the equipment,” DeMilio tells BD+C. But inside jobs aside, the industry has a “natural exposure” to theft because jobsites are on predictable schedules, leaving opportunities open for thieves will often scope out sites looking for weak spots.

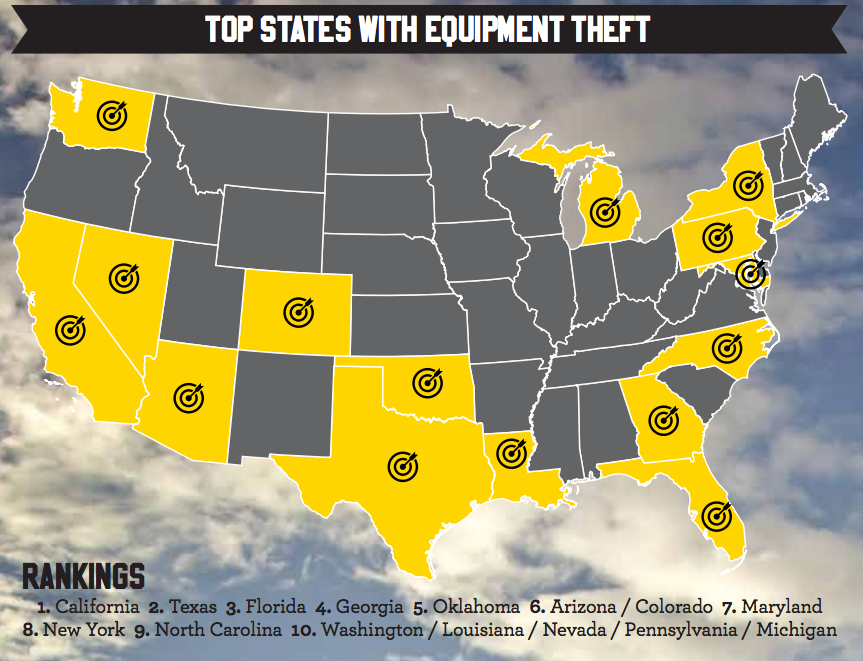

Not surprisingly, theft is more prevalent in states where there’s more construction activity, with California and Texas having the highest occurrences. But unlike cars, which when stolen often end up in other states, 95% of the stolen construction equipment and tools that are recovered are found in the same state they were stolen in.

DeMilio says contractors and owners need to keep their equipment off the street in secured areas patrolled by guards. They should also be in close contact with police “so they are aware of the area and can be monitoring during off hours.” She recommends that owners adopt technology that includes cameras, electronic access pads, GPS geo-fencing, and covert RF recover devices.

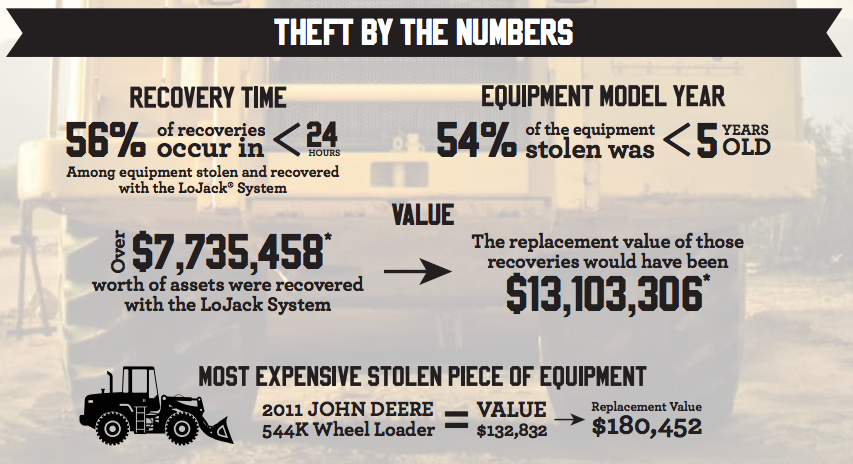

LoJack, naturally, pitches the efficacy of installing detection and telematic devices on construction equipment so that owners are alerted to unauthorized use during off hours, and police have a better shot at retrieving stolen goods. It points out that 56% of stolen equipment with a LoJack system was recovered within 24 hours after being reported, and 5% was recovered within an hour.

Related Stories

Student Housing | Jul 1, 2024

Two-tower luxury senior living community features wellness and biophilic elements

A new, two-building, 27-story senior living community in Tysons, Va., emphasizes wellness and biophilic design elements. The Mather, a luxury community for adults aged 62 and older, is situated on a small site surrounded by high-rises.

Contractors | Jul 1, 2024

Nonresidential construction spending slips 0.1% in May but remains elevated

National nonresidential construction spending decreased 0.1% in May, according to an Associated Builders and Contractors analysis of data published today by the U.S. Census Bureau. On a seasonally adjusted annualized basis, nonresidential spending totaled $1.21 trillion.

Contractors | Jul 1, 2024

New emergency cooling vest can prevent heat-related deaths on construction sites

A new emergency cooling vest is designed to prevent heat-related deaths without requiring electricity or refrigeration. The lightweight ColdVest is the world’s first portable, Class 1 FDA emergency cooling device that can rapidly lower core body temperatures up to 5 degrees in under 3 minutes.

Smart Buildings | Jul 1, 2024

GSA to invest $80 million on smart building technologies at federal properties

The U.S. General Services Administration (GSA) will invest $80 million from the Inflation Reduction Act (IRA) into smart building technologies within 560 federal buildings. GSA intends to enhance operations through granular controls, expand available reporting with more advanced metering sources, and optimize the operator experience.

Sustainability | Jul 1, 2024

Amazon, JPMorgan Chase among companies collaborating with ILFI to advance carbon verification

Four companies (Amazon, JPMorgan Chase, JLL, and Prologis) are working with the International Living Future Institute to support development of new versions of Zero Carbon Certification.

K-12 Schools | Jul 1, 2024

New guidelines for securing schools and community spaces released by the Door Security and Safety Foundation

The Door Security and Safety Foundation (DSSF), in collaboration with Door and Hardware Institute (DHI), recently released of “Are Your Door Openings Secure?.” The document provides guidelines to equip school administrators, building management personnel, and community leaders with a clear roadmap to create a secure and safe environment.

University Buildings | Jun 28, 2024

The American University in Cairo launches a 270,000-sf expansion of its campus in New Cairo, Egypt

In New Cairo, Egypt, The American University in Cairo (AUC) has broken ground on a roughly 270,000-sf expansion of its campus. The project encompasses two new buildings intended to enhance the physical campus and support AUC’s mission to provide top-tier education and research.

MFPRO+ New Projects | Jun 27, 2024

Chicago’s long-vacant Spire site will be home to a two-tower residential development

In downtown Chicago, the site of the planned Chicago Spire, at the confluence of Lake Michigan and the Chicago River, has sat vacant since construction ceased in the wake of the Great Recession. In the next few years, the site will be home to a new two-tower residential development, 400 Lake Shore.

Codes and Standards | Jun 27, 2024

Berkeley, Calif., voters will decide whether to tax large buildings with gas hookups

After a court struck down a first-in-the-nation ban on gas hookups in new buildings last year, voters in Berkeley, Calif., will have their say in November on a measure to tax large buildings that use natural gas.

Mass Timber | Jun 26, 2024

Oregon State University builds a first-of-its-kind mass timber research lab

In Corvallis, Oreg., the Jen-Hsun Huang and Lori Mills Huang Collaborative Innovation Complex at Oregon State University aims to achieve a distinction among the world’s experimental research labs: It will be the first all-mass-timber lab meeting rigorous vibration criteria (2000 micro-inches per second, or MIPS).