There probably isn’t a contractor in this country that at some point hasn’t been a victim of jobsite theft. In 2014, there were 11,625 heavy-equipment thefts reported to law enforcement, up 1.2% from 2013, according to the latest data from the National Insurance Crime Bureau in a report coproduced by the National Crime Information Center.

Total construction equipment theft now stands at around $1 billion annually. And only 23% of the heavy equipment stolen last year was recovered, the NICB report stated.

A survey conducted last year by Cygnus Business Media Research on behalf of LoJack, which makes theft-detection and –prevention devices, found that 83% of construction equipment owners polled had experienced equipment theft.

Courtney DeMilio, LoJack’s National Vice President of Commercial and Fleet, points out that theft can have a greater, negative impact on a business. “Loss in job productivity, the inability to complete a job, a diminished professional reputation—all while the owner is spending a substantial amount of time and money to replace the equipment,” she says.

The Canton, Mass.-based LoJack recently released its annual “Construction Equipment Theft and Recovery in the United States” report, based on its tracking, from January through December 2014, of theft reports in 28 states where equipment theft was reported and where construction equipment outfitted with a LoJack device led police to recover the stolen assets.

Graphics courtesy LoJack

Graphics courtesy LoJack

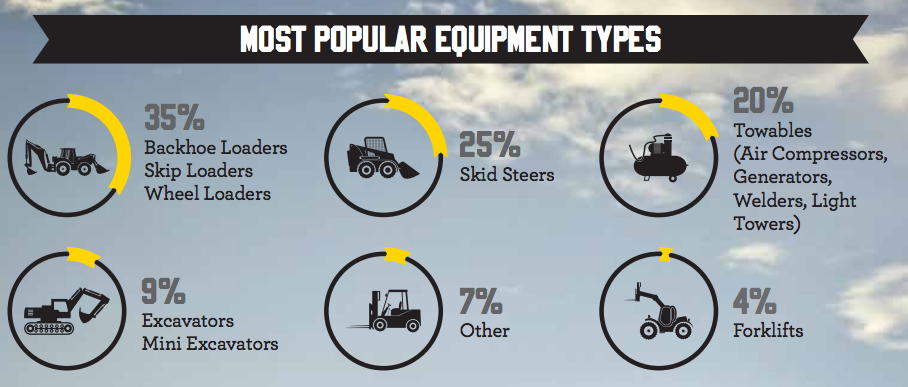

From that sample, the report identifies backhoe loaders, skip loaders and wheel loaders as the most popular equipment targeted by thieves. “There is little visual differentiation from one backhoe to another, and they all share a common key,” the report explains. “Therefore, they are prime targets for thieves based on the ease of theft and how hard they are to track once one is stolen.”

Skid steers, generators/air compressors/welders and portable light towers; and excavators are also most susceptible to robbery.

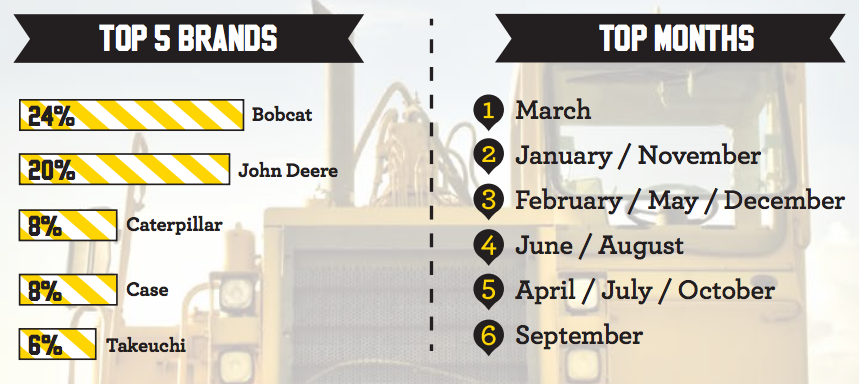

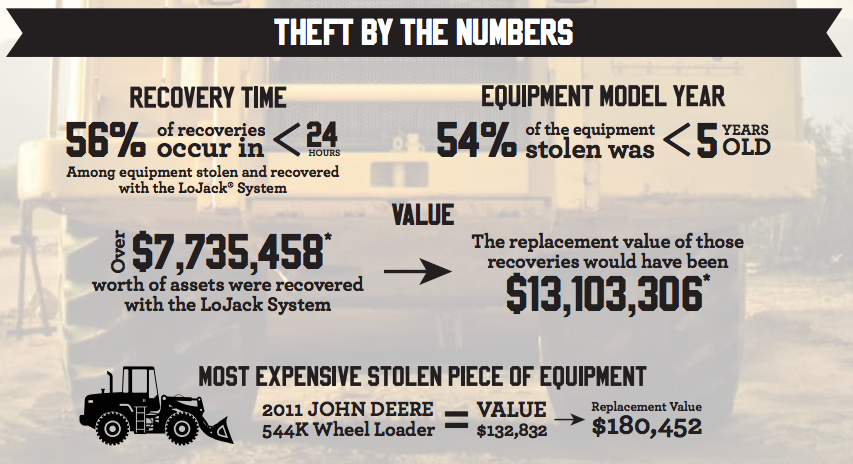

The report notes that thieves typically go after newer and brand-name equipment. In 2014, 54% of the tracked equipment stolen was less than five years old. And 65% of the thefts were of products made by top manufacturers such as Bobcat (24% of the equipment stolen), John Deere (20%), Caterpiller and Case (tied at 8% each), Takeuchi (6%) and Magnum (5%).

The report gives several reasons why construction equipment and tools continue to be vulnerable to thieves. For one thing, titling and registration of equipment aren’t mandated, so it’s often hard to report theft and harder for law enforcement to track what’s stolen. There’s also no standardized identification numbers on this stuff, like the Vehicle Identification Numbers on cars and trucks.

In addition, jobsite security is not always as tight as it could be, and the sites themselves can be remote. And because equipment and tools are constantly being transferred between sites, owners can be lax in their inventory accounting.

“The thief isn’t always somebody unrelated to the job, as often he or she can be a member of the company that owns the equipment,” DeMilio tells BD+C. But inside jobs aside, the industry has a “natural exposure” to theft because jobsites are on predictable schedules, leaving opportunities open for thieves will often scope out sites looking for weak spots.

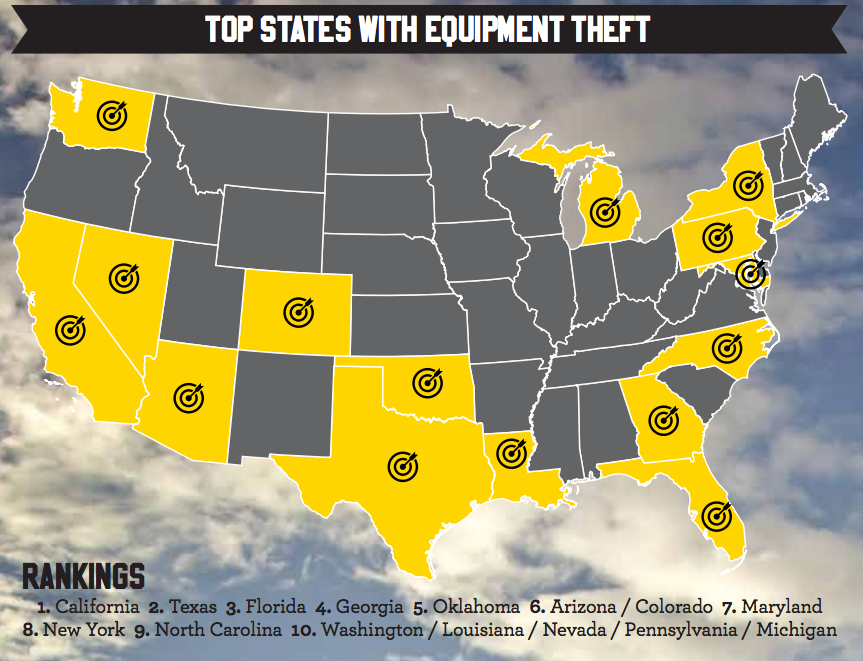

Not surprisingly, theft is more prevalent in states where there’s more construction activity, with California and Texas having the highest occurrences. But unlike cars, which when stolen often end up in other states, 95% of the stolen construction equipment and tools that are recovered are found in the same state they were stolen in.

DeMilio says contractors and owners need to keep their equipment off the street in secured areas patrolled by guards. They should also be in close contact with police “so they are aware of the area and can be monitoring during off hours.” She recommends that owners adopt technology that includes cameras, electronic access pads, GPS geo-fencing, and covert RF recover devices.

LoJack, naturally, pitches the efficacy of installing detection and telematic devices on construction equipment so that owners are alerted to unauthorized use during off hours, and police have a better shot at retrieving stolen goods. It points out that 56% of stolen equipment with a LoJack system was recovered within 24 hours after being reported, and 5% was recovered within an hour.

Related Stories

Student Housing | Jun 25, 2024

P3 student housing project with 176 units slated for Purdue University Fort Wayne

A public/private partnership will fund a four-story, 213,000 sf apartment complex on Purdue University Fort Wayne’s (PFW’s) North Campus in Fort Wayne, Indiana. The P3 entity was formed exclusively for this property.

Sustainability | Jun 24, 2024

CBRE to use Climate X platform to help clients calculate climate-related risks

CBRE will use risk analysis platform Climate X to provide climate risk data to commercial renters and property owners. The agreement will help clients calculate climate-related risks and return on investments for retrofits or acquisitions that can boost resiliency.

MFPRO+ News | Jun 24, 2024

‘Yes in God’s Backyard’ movement could create more affordable housing

The so-called “Yes in God’s Backyard” (YIGBY) movement, where houses of worship convert their properties to housing, could help alleviate the serious housing crisis affecting many communities around the country.

Student Housing | Jun 20, 2024

How student housing developments are evolving to meet new expectations

The days of uninspired dorm rooms with little more than a bed and a communal bathroom down the hall are long gone. Students increasingly seek inclusive design, communities to enhance learning and living, and a focus on wellness that encompasses everything from meditation spaces to mental health resources.

Museums | Jun 20, 2024

Connecticut’s Bruce Museum more than doubles its size with a 42,000-sf, three-floor addition

In Greenwich, Conn., the Bruce Museum, a multidisciplinary institution highlighting art, science, and history, has undergone a campus revitalization and expansion that more than doubles the museum’s size. Designed by EskewDumezRipple and built by Turner Construction, the project includes a 42,000-sf, three-floor addition as well as a comprehensive renovation of the 32,500-sf museum, which was originally built as a private home in the mid-19th century and expanded in the early 1990s.

Building Technology | Jun 18, 2024

Could ‘smart’ building facades heat and cool buildings?

A promising research project looks at the possibilities for thermoelectric systems to thermally condition buildings, writes Mahsa Farid Mohajer, Sustainable Building Analyst with Stantec.

University Buildings | Jun 18, 2024

UC Riverside’s new School of Medicine building supports team-based learning, showcases passive design strategies

The University of California, Riverside, School of Medicine has opened the 94,576-sf, five-floor Education Building II (EDII). Created by the design-build team of CO Architects and Hensel Phelps, the medical school’s new home supports team-based student learning, offers social spaces, and provides departmental offices for faculty and staff.

Mass Timber | Jun 17, 2024

British Columbia hospital features mass timber community hall

The Cowichan District Hospital Replacement Project in Duncan, British Columbia, features an expansive community hall featuring mass timber construction. The hall, designed to promote social interaction and connection to give patients, families, and staff a warm and welcoming environment, connects a Diagnostic and Treatment (“D&T”) Block and Inpatient Tower.

Codes | Jun 17, 2024

To avoid lawsuits, contractors and designers need to do more than comply with codes

Climate change is making design and construction more challenging and increasing the potential for lawsuits against building teams, according to insurance experts. Building to code is not enough to reduce liability because codes have not kept up with the rapid climate changes that are making extreme weather more common.

Concrete Technology | Jun 17, 2024

MIT researchers are working on a way to use concrete as an electric battery

Researchers at MIT have developed a concrete mixture that can store electrical energy. The researchers say the mixture of water, cement, and carbon black could be used for building foundations and street paving.