The University of Massachusetts Medical School in Worcester, Mass., held grand opening ceremonies on October 4 for its new Massachusetts Facility for High-Resolution Cyro-Electron Microscopy, the first of its kind in New England, and one of only a handful of similar facilities nationwide.

TRO Architects designed this $20 million, 4,100-sf facility, for which Consigli was construction manager.

Cryo-Electron Microscopy, or cyro-EM, was recently called the “research method of the year” by Nature magazine. “Cryo-EM is particularly well suited for obtaining structural information for large protein complexes and for systems that exhibit multiple conformational or compositional states,” the magazine explained.

By first plunging particle samples into liquid nitrogen, cyro-EM processes images of particles at near-atomic levels. It is said to be revolutionizing structural biology by helping to identify likely therapeutic approaches to a broad range of diseases, including neurological ailments such as Alzheimer’s. “With cryo-EM, we can look at detailed mechanisms and dynamics in molecules and complexes of molecules to understand their functions, dissecting each step to have a high-resolution picture of how they work,” said UMMS structural biologist Andrei Korostelev, Ph.D, associate professor in the RNA Therapeutics Institute and of biochemistry & molecular pharmacology.

The new facility includes a 2,000-sf microscopy suite for its two microscopes: Titan Krios, which is said to be the most sophisticated cyro-EM in the world, and whose purchase was supported by a $5 million grant from the Massachusetts Life Science Center; and the powerful, versatile Talos-Arctica, whose $4 million cost was funded by the Howard Hughes Medical Institute.

Titan Krios was delivered to the medical school last summer in 19 crates. When assembled, it is nearly 13.5 feet tall.

The building had exacting requirements for vibration, acoustical and climate control (the microscopes’ environment can tolerate only 0.1 degree change in an hour, and relative humidity must always be below 20%.) To meet those requirements, the Building Team built what essentially is a five-roomed box, constructed with eight-layered walls, floors, and ceilings. The nearly two-feet-thick construction isolates and protects the microscopes and adjacent spaces that support their use from noise, sound, and movement.

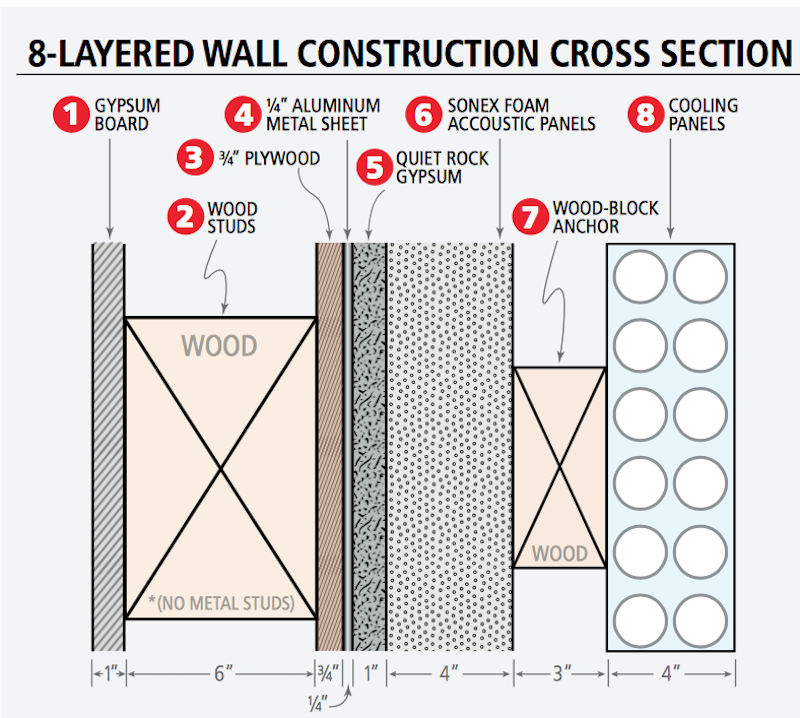

To address sound, vibration, and temperature controls, the Building Team devised this system for walls, floors, and ceilings. Image: Consigli Construction

Mark Morrow, Consigli’s manager on this project, explains that the eight layers include an outer layer of one-inch gypsum wallboard and six-inch wood studs. Consigli used wood, instead of more typical metal studs, to eliminate vibration.

Over the wood studs is a layer of ¾-inch plywood, to which is attached a ¼-inch thickness of aluminum sheeting. Over the aluminum panels Consigli installed 1-inch-thick acoustical drywall panel, “Quiet Rock,” which incorporates a damping technique called “constrained-layer damping,” creating a higher ability to dampen vibrational and acoustical energy. Next came 4-inch-thick “Sonex” foam acoustical panels, to which are attached 3-inch wood block anchors to assure a secure attachment of the final layer, 4-inch-wide cooling panels.

Because the aluminum welding was conducted within a healthcare facility, mitigation that limited smoke and smell was required. Morrow says that coordination with all of the project’s trades and specialty subcontractors—which included the electromagnetic shielding company Vitatech Electromagnetics—was critical to the successful construction of this facility, as was working with the facilities’ director, electron microscopist Chen Xu, Ph.D; and the project’s superintendent Tim Backlin.

The completed facility includes a lab to prepare the research samples, staff offices, a mechanicals room, space for a possible third microscope, and space for computer resources. Chen says that about 100,000 particle projections are needed in order to see a particle structure. “You're talking about a lot of data.”

Related Stories

| Jul 18, 2014

2014 Giants 300 Report

Building Design+Construction magazine's annual ranking the nation's largest architecture, engineering, and construction firms in the U.S.

| Jul 7, 2014

7 emerging design trends in brick buildings

From wild architectural shapes to unique color blends and pattern arrangements, these projects demonstrate the design possibilities of brick.

| Jul 2, 2014

Emerging trends in commercial flooring

Rectangular tiles, digital graphic applications, the resurgence of terrazzo, and product transparency headline today’s commercial flooring trends.

| Jun 18, 2014

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 12, 2014

Austrian university develops 'inflatable' concrete dome method

Constructing a concrete dome is a costly process, but this may change soon. A team from the Vienna University of Technology has developed a method that allows concrete domes to form with the use of air and steel cables instead of expensive, timber supporting structures.

| Jun 9, 2014

Green Building Initiative launches Green Globes for Sustainable Interiors program

The new program focuses exclusively on the sustainable design and construction of interior spaces in nonresidential buildings and can be pursued by both building owners and individual lessees of commercial spaces.

| May 29, 2014

7 cost-effective ways to make U.S. infrastructure more resilient

Moving critical elements to higher ground and designing for longer lifespans are just some of the ways cities and governments can make infrastructure more resilient to natural disasters and climate change, writes Richard Cavallaro, President of Skanska USA Civil.

| May 20, 2014

Kinetic Architecture: New book explores innovations in active façades

The book, co-authored by Arup's Russell Fortmeyer, illustrates the various ways architects, consultants, and engineers approach energy and comfort by manipulating air, water, and light through the layers of passive and active building envelope systems.

| May 19, 2014

What can architects learn from nature’s 3.8 billion years of experience?

In a new report, HOK and Biomimicry 3.8 partnered to study how lessons from the temperate broadleaf forest biome, which houses many of the world’s largest population centers, can inform the design of the built environment.

| May 13, 2014

19 industry groups team to promote resilient planning and building materials

The industry associations, with more than 700,000 members generating almost $1 trillion in GDP, have issued a joint statement on resilience, pushing design and building solutions for disaster mitigation.