For years we have been told that the benefits of prefabrication often parallel those of building information modeling: increased safety and efficiency, higher quality, and reduced labor and material costs. Contractor Brasfield & Gorrie’s use of BIM and prefabrication on the $94 million WellStar Paulding Hospital in Hiram, Ga., is an excellent case study of how digital tools can inform prefabrication and lead to project savings, a safer work environment, and better-delivered construction.

The 100-bed Wellstar Paulding Hospital is one of the first hospitals in the U.S. to rely almost entirely on geothermal energy. The scope of the 24-month project took in 33 acres of site work, including a one-level, 120,000-sf precast parking deck; site utilities; modular block and concrete retaining walls; an eight-story, 295,700-sf hospital; a four-story, 82,220-sf medical office building; and a seven-story atrium that links the site’s two medical office buildings to the new hospital.

The design of the geothermal system called for 35,000 sf of radiant floor piping to heat and cool the atrium and high-ceiling areas. The ground-source heat pump system utilizes 209 wells, each 400 feet deep, with a total of about 38 miles of piping. The GSHP equipment included six chiller/heat pump modules, each with capacity for 110 tons of cooling and 2,038 MBH of heating.

The system has three sets of pumps: one for hot water, one for chilled water, and one for ground-loop circulation. More than half of the facility’s 700-ton total building cooling load is handled by the GSHP system. The remainder is managed by the air-cooled chillers. The GSHP system also handles the building heating and domestic hot water load of approximately 5,000 MBH.

With such complexity involved, both in the construction of the new hospital and connecting it with the medical office buildings, Brasfield & Gorrie turned to laser scanning and a sophisticated BIM program to inform its construction decisions.

VDC Modeling Starts the Process

Brasfield & Gorrie’s Virtual Design and Construction group created BIM models and collaborated in real time with the design team (including architect CPH Partners and engineering firm PerryCrabb) through more than 23 revision packages. Models were created in Autodesk Revit and reviewed in Autodesk Navisworks.

The BIM process correlated with the construction schedule, and was carefully planned as part of the overall project schedule. Each floor was modeled; each model included every trade and discipline.

The first step was to model everything under the basement slab, such as underground plumbing and electrical conduit. This model alone resolved 50 conflicts, including invert tie-in elevations with building and site storm systems and sloping grade beams with underground conduit.

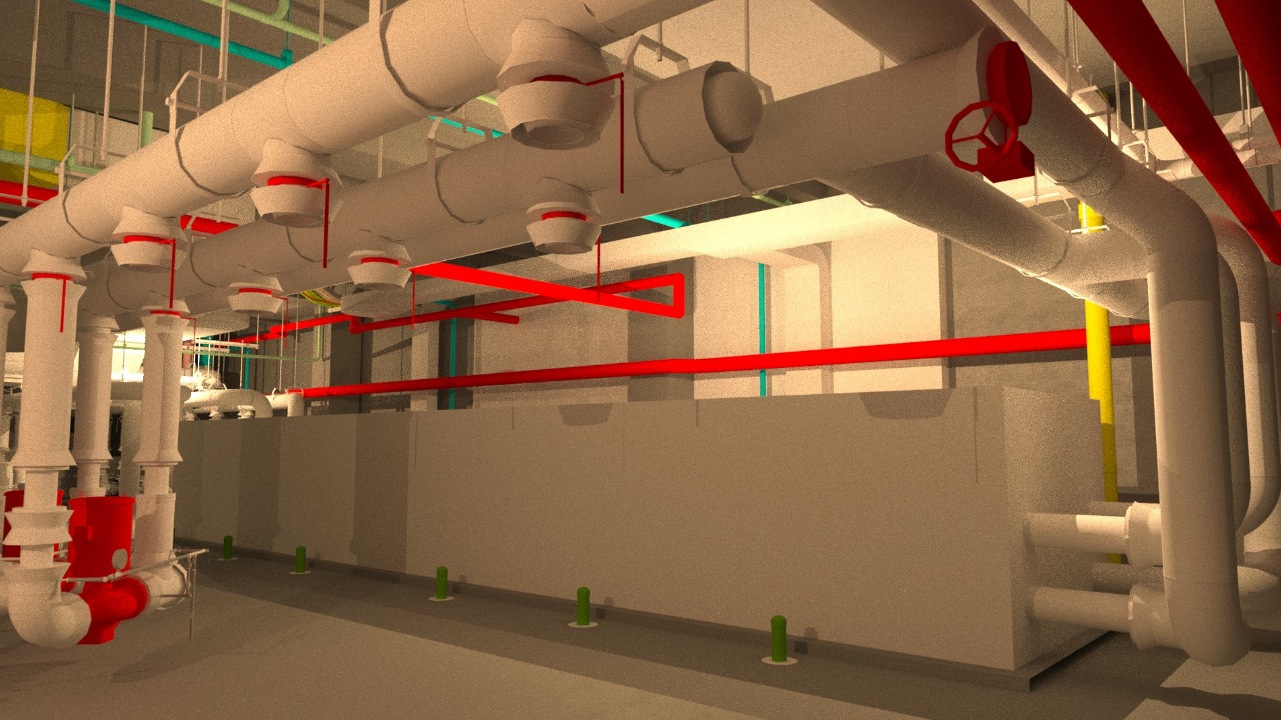

The $94 million WellStar Paulding Hospital in Hiram, Ga., is one of the first hospitals in the U.S. to rely almost entirely on geothermal energy. General contractor Brasfield & Gorrie worked with key subcontractors to create a comprehensive VDC model of the hospital’s systems.

The $94 million WellStar Paulding Hospital in Hiram, Ga., is one of the first hospitals in the U.S. to rely almost entirely on geothermal energy. General contractor Brasfield & Gorrie worked with key subcontractors to create a comprehensive VDC model of the hospital’s systems.

Utilizing existing conditions data imported from Trimble scans, the team was able to streamline the placement and installation of the hangers. “The efficiency in layout for hanger locations was achieved through the use of detailed models showing all locations, or insert points, where the hangers were needed,” says Scott Cloud, Brasfield & Gorrie’s Director of VDC.

The Building Team was able to coordinate the hanger locations within the model. Robotic total stations were utilized once formwork was completed and prior to concrete pours. Because the team was able to locate inserts within the concrete slabs as the structure was completed, it eliminated the need to drill/epoxy hangers in the concrete deck, post-shore removal. Not only did this allow for gains in schedule, it supported Brasfield & Gorrie’s ability to prefabricate larger assemblies for MEP overhead utilities and improved overall safety on the job by eliminating extra stockpiles of materials.

Electrical contractor Inglett & Stubbs exported data from the construction model to the company’s prefabrication department so that boxes and conduit could be built and delivered to the site already connected and ready for placement. All prefabricated units—junction boxes, conduit assemblies—and trapeze hanger assemblies were completed off site within Inglett & Stubbs’s shop.

Sheet metal contractor R.F. Knox Co. used the construction model for accurate prefabrication of ductwork and other metal components. The detailed development of the models fully supported material procurement for ductwork, piping, conduit, and even some equipment.

Because the BIM coordination process began nearly four months prior to the start of the elevated structure, the team was able to approve the fabrication design shop drawings and release material fabrication much earlier in the process than usual. As owner changes in the design occurred throughout construction, the detailed models aided in quicker and more accurate response times to pricing changes.

“When one section of the hospital originally designated as clinical office space changed to surgery recovery, we were able to quickly adapt to help complete a design that met design intent,” says Cloud, “but accurately relayed routing paths for utilities that would impact MEP material quantities.”

Sure Shoring with Shotcrete

Brasfield & Gorrie specified a shotcrete wall to hold up the foundation, and used a field survey to model the shotcrete wall virtually and coordinate the material for the slab rebar and penetrations.

A Brasfield & Gorrie field crew surveyed a series of points along the wall. This information was used to develop a 3D model of the wall, which was then incorporated within the composite model to coordinate MEP penetrations and structural dimensions, based on the actual dimensional survey information taken from the field.

Once coordinated in the model, this information was shared with the formwork, rebar, and MEP contractors to support material fabrication, release, deliveries, and installation in the field.

Using existing conditions data collected through laser scanning, the Building Team was able to coordinate the MEP systems hanger locations within the model. Robotic total stations were utilized to locate each hanger insert point within the concrete slabs as the structure was completed.

Using existing conditions data collected through laser scanning, the Building Team was able to coordinate the MEP systems hanger locations within the model. Robotic total stations were utilized to locate each hanger insert point within the concrete slabs as the structure was completed.

Related Stories

| Apr 27, 2012

China Mobile selects Leo A Daly to design three buildings at its new HQ

LEO A DALY, in collaboration with Local Design Institute WDCE, wins competition to design Phase 2, Plot B, of Campus.

| Apr 24, 2012

McLennan named Ashoka Fellow

McLennan was recognized for his work on the Living Building Challenge.

| Apr 18, 2012

Positive conditions persist for Architecture Billings Index

The AIA reported the March ABI score was 50.4, following a mark of 51.0 in February; greatest demand is for commercial building projects.

| Mar 30, 2012

18 handy tablet apps for AEC professionals

Check out these helpful apps for everyday design and construction tasks. Our favorite: MagicPlan, which uses GPS to help you measure and draw a floor plan of any room.

| Mar 21, 2012

10 common data center surprises

Technologies and best practices provide path for better preparation.

| Mar 7, 2012

Firestone iPad app offers touch technology

Free app provides a preview of Firestone’s Roots to Rooftop Building Envelope Solution with an overview of all the products from ground and stormwater management solutions, to complete wall panel and commercial roofing system applications.

| Mar 1, 2012

Intelligent construction photography, not just pretty pictures

Our expert tells how to organize construction progress photos so you don’t lose track of all the valuable information they contain.

| Mar 1, 2012

AIA: A clear difference, new developments in load-bearing glass

Earn 1.0 AIA/CES learning units by studying this article and successfully completing the online exam.

| Mar 1, 2012

Cornell shortlists six architectural firms for first building on tech campus

Each of the firms will be asked to assemble a team of consultants and prepare for an interview to discuss their team’s capabilities to successfully design the university’s project.

| Feb 22, 2012

ACI BIM manual for cast-in-place concrete in development

The improved communication, coordination, and collaboration afforded by BIM implementation have already been shown to save time and money in projects.