Big timber is sprouting up in cities in North America and abroad. After years of feasibility studies and design proposals, buildings six stories or taller constructed primarily from pre-engineered wood products are being considered in cities around the world.

In London, one proposal, called the Splinter, would rise to 100 stories. In Chicago, Perkins+Will (in collaboration with Thornton Tomasetti and the University of Cambridge) has designed an 80-story high-rise with 300 duplex apartments. If built, River Beech—a key component of P+W’s master plan for the Riverline development—would be made almost entirely from mass timber.

So-called “plyscrapers” are still a tiny sliver of nonresidential construction. In the past five years, only 17 buildings seven stories or taller have been completed worldwide, mostly in Europe and Canada. Six more have started construction, according to the American Wood Council.

Mass production of timber for high-rise construction is still in its infancy in North America. Specifying these products in the U.S. faces resistance from insurers, regulators, and code officials. Steel fabricators and concrete suppliers disparage mass timber for taller buildings on the grounds of safety and durability.

Proponents cite the speed at which tall buildings can be constructed using pre-engineered wood and mass timber’s ability to sequester carbon. Joey-Michelle Hutchison, RA, LEED AP BD+C, CSBA, Associate Vice Principal, CallisonRTKL, says, “The role of mass wood is going to grow because of the demand for sustainable design.” Researchers from Yale and the University of Washington, in a study published in the Journal of Sustainable Forestry (March 28, 2014), postulated that using wood substitutes for constructing buildings (and bridges) could save 14–31% of global CO2 emissions.

“The barriers are eroding,” says Iain MacDonald, Associate Director, National Center for Advanced Wood Products Manufacturing. “If wood took even 5% market share from steel or concrete, that would be major” in terms of reducing CO2 emissions from new construction. The International Code Council’s board has created a Tall Wood Ad Hoc Committee to look into possible code changes for the 2021 IBC.

MacDonald came to the center—a collaboration between Oregon State University’s Colleges of Forestry and Engineering and the University of Oregon’s School of Architecture—from the University of British Columbia, Vancouver. That’s where the world’s tallest wood building—Brock Commons, a 174-foot residence hall for 404 students—should be completed this spring.

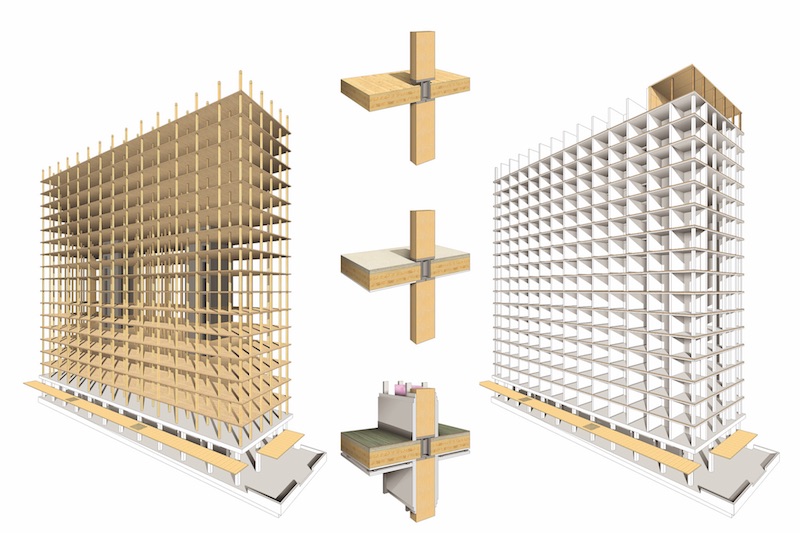

The $38 million project employs a hybrid structural system: a one-story concrete podium, two concrete cores, and 17 stories of mass timber—glulam columns with steel connectors supporting five-ply cross-laminated timber (CLT) on a 2.85x4-meter grid—topped with a prefabricated steel beam and metal roof deck. The prefab façade is comprised of eight-meter-long steel stud frames with preinstalled windows. A 58-meter CLT canopy runs the length of the building base.

Mass timber is well suited for constructing high-rise student housing, says Paul Fast, Partner, Fast + Epp, the structural engineering firm on Brock Commons. The suites are only 14 feet wide, “so you could put in a lot of structural wood posts” for support, he says. Columns run every 10 feet, and the crawl spaces are less than 10 feet, “so it could go up really fast.”

The construction management firm, Urban One, completed two stories per week; the structural system, consisting of 1,302 glulam columns and 464 CLT panels, was finished in 66 days. Fast says that with a few more cranes and carpenters, “You could build a floor a day.”

The 12-story Framework, whose construction in Portland, Ore., gets started in February, will be made primarily with CLT. To meet seismic objectives, the building will include a lateral-force resisting system with post-tensioned rocking wood shear walls, pioneered in New Zealand. In November, Framework’s fully loaded exposed CLT and glulam connections were the first to achieve two-hour fire ratings. The Building Team: project^ (developer), Lever Architecture, KPFF (SE, CE), PAE (MEP), Arup (fire and timber engineer), StructureCraft Builders (timber structure delivery partner), and Walsh Construction (GC). Rendering: Lever Architecture.

“The 21st century will be the age of wood,” thanks to demand for sustainability and the prospect of carbon taxes, says Lucas Epp, Engineering and 3D Manager for StructureCraft Builders, the timber structure delivery partner on the seven-story, 224,000-sf T3 in Minneapolis’s North Loop. T3—which stands for “timber, technology, transportation”—is the first tall wood office building in the U.S. It wrapped up construction in November.

StructureCraft installed 180,000 sf of timber superstructure, including 1,100 8x20-foot nail-laminated timber panels, in 9½ weeks. (Nail-lam, or NLT, is created by nailing individual units of dimensional lumber, stacked on edge, into a single structural element.) Michael Green Architecture and DLR Group designed the building.

Hines, T3’s owner and developer, declined to be interviewed. But two sources familiar with the project told BD+C that Hines plans to build other tall wood buildings across the country. “They’re looking to get a jump on the market,” one source said.

StructureCraft is also involved in Framework, a 12-story mixed-use building in Portland, Ore., whose developer is the unusually named project^. Its structural system will consist of CLT and glulam beams and columns, supported by a reinforced concrete foundation. When completed in Q1/2018, Framework will offer 60 apartments, 39,000 sf of offices, and 9,000 sf of retail.

At 130 feet in height, Framework will be the first tall wood building in North America with post-tensioned rocking CLT shear walls. Coupled with replaceable energy-diffusing “fuses” on the periphery, the building will meet the required seismic performance criteria of “economically repairable” after a 1:500-year earthquake and “little or no damage” after a 1:100-year event.

“Mass wood has a high strength-to-weight ratio, which makes it good for protecting against seismic events,” says Thomas Robinson, Founder, Lever Architecture, Framework’s architect. Robinson is so enamored of mass wood that he recently moved his firm into the four-story, 16,000-sf Albina Yard in North Portland, the first market-rate office building in the U.S. constructed with domestically fabricated CLT.

Preconstruction planning is essential to familiarize subcontractors with these components. “A lot of thinking is done before the wood gets to the job site,” says Valerie Johnson, President, D.R. Johnson Wood Innovations, Riddle, Ore., the sole CLT plant in the U.S.

Proponents hope mass timber catches on in the U.S. the way it has in Canada and Europe.

One such Canadian project is the Origine Condos, a 13-story, 92-unit residential tower in Quebec City. It took the NEB consortium—Nordic Structures (wood structure manufacturer), EBC (GC), and Synchro Immobilier (developer)—four years to get the 426-foot-tall structure approved. The project, designed by Yvan Blouin Architects (with engineering firms WSP Canada, Génécor, and Groupe Conseil SID), broke ground last June and is scheduled for completion in June.

LEANING TOWARD HYBRID SOLUTIONS

Mass timber is less practical or cost effective for building typologies with large, open floor plans. That’s one reason why most tall wood buildings are still hybrids with steel and concrete.

Last November, building crews completed the UMass Amherst Design Building, a four-story, 87,500-sf, $52 million project whose “zipper truss,” a composite of mass timber and compressed elements, is reinforced with steel rods. “We needed the steel because of the length, which reaches up to 70 feet,” says Tom Chung, AIA, LEED AP, Principal, Leers Weinzapfel Associates Architects, the design firm on the project.

At the Mass Timber Conference last March, structural engineer Benton Johnson, an Associate with Skidmore Owings & Merrill, stated that, after studying the feasibility of high-rise wood up to 42 stories, SOM had concluded that a composite structure with mass timber floors and walls connected by reinforced concrete joints is “more flexible” than wood alone would be.

“Hybrid is the only way to go for proper wind resistance and rigidity,” says Amir Lotfi, LEED AP BD+C, Architectural Associate, CallisonRTKL. His firm has conducted a feasibility study for a 1,325-foot, 110-floor building in Seattle that would have a concrete and steel framework.

AEC firms are eager to integrate mass timber because it is a renewable resource that’s environmentally friendlier than either concrete or steel, whose production and off-gassing leave enormous carbon footprints on the built environment. StructureCraft claims that the 127,133 cubic feet of wood used for T3 would sequester 3,200 tons of CO2 during the life of the building.

Illustration depicts the hybrid structural system design at the Brock Commons project, at the University of British Columbia, Vancouver. 1] Hybrid mass timber and concrete core structure. 2] CLT floor slabs with glulam columns and steel connectors. 3] Partial encapsulation during construction. 4] Completed construction. Courtesy Acton Ostry Architects.

REMOVING A FEW ROADBLOCKS

Objections to tall wood buildings as potential firetraps are still embedded in codes and regulations, says Alan Bruton, NCARB, NCIDQ, Associate Professor at the University of Houston’s College of Architecture and Design. Sandy Springs, Ga., recently banned wood buildings taller than three stories or bigger than 100,000 sf.

At press time, SHoP Architects was negotiating with the New York City Fire Department for approval of 475 West 18th Street, a 10-story, 15-unit condominium building that would be made primarily from mass timber.

“Our firm has gotten interest from other clients, but when we ask about getting approval, we usually don’t hear back,” says Russell Acton, AIBC, AAA, SAA, OAA, FRAIC, Principal, Acton Ostry Architects, the architect on Brock Commons.

To move wood projects to the next level, Bruton says the AEC community and manufacturers must conduct full-scale fire tests and provide consistent data to municipalities.

Last October, The Framework Project LLC (which owns Framework) announced that two fire tests of CLT and glulam had achieved two-hour fire ratings, which showed that mass timber could meet stringent fire code requirements. In August, D.R. Johnson’s CLT panels met fire safety requirements under tests that gauge flame spread and fire resistance.

Regulations aside, any expansion in mass timber’s market penetration would require more production capacity. Only three plants in North America are certified to make CLT, compared to 14 in Europe. Right now, it’s cheaper to ship mass timber from Europe to the U.S. than to truck it in from Oregon or Canada.

MDS 10 Architects, Asheville, N.C.—designer of the six-story Veterans Village with 88 units for homeless vets, which is under construction using CLT—is shifting its business to manufacturing. The firm is raising money to build a CLT plant in Stuart, Va. The plant would be the first to use Southern yellow pine as its base material.

MDS 10’s co-owners, Crawford Murphy and Michael DeVere, see mass timber as “the technology of now and the future.” They say that when they present mass timber products to developers and builders, the reaction has gone from “What’s that?” to “Wow!”

Related Stories

Game Changers | Jan 16, 2018

Shape shifters: Kinetic architecture allows buildings to perform beyond their intended purpose

Kinetic architecture can bring practical and aesthetic value to an already ambitious project.

Game Changers | Jan 15, 2018

Innovation studio sparks AEC startups

Autodesk’s BUILD Space gives AEC firms and research teams free use of a robust collection of fabrication equipment and software expertise.

Game Changers | Jan 12, 2018

‘Kit of parts’ anchors university’s remake

Sasaki designs interchangeable spaces to support a major educational shift at Mexico’s largest university system.

Game Changers | Dec 20, 2017

Urban farms can help plant seeds for cities’ growth around them

Urban farms have been impacting cities’ agribusiness—and, on some cases, their redevelopment—for decades.

Mixed-Use | Aug 30, 2017

A 50-acre waterfront redevelopment gets under way in Tampa

Nine architects, three interior designers, and nine contractors are involved in this $3 billion project.

Projects | Jan 25, 2017

Trump prioritizes infrastructure projects, as rebuilding America is now a hot political potato

Both parties are talking about $1 trillion in spending over the next decade. How projects will be funded, though, remains unresolved.

Game Changers | Jan 19, 2017

Piezoelectric hits the road

GTRI recently got the OK from the Georgia Department of Transportation to test embedded PZ material supplied by Tencate in a stretch of road and rest stop surfaces at West Point, Ga.

Game Changers | Jan 18, 2017

Turning friction into power

Research on piezoelectricity moves closer to practical applications for infrastructure and buildings.

Game Changers | Jan 13, 2017

Building from the neighborhood up

EcoDistricts is helping cities visualize a bigger picture that connects their communities.

Game Changers | Feb 5, 2016

TIMELINE: 52 game-changing buildings through the years

From the E.V. Haughwout Building (first passenger elevator) to the Sackett-Wilhelms printing plant (first building with modern AC), BD+C editors present a timeline of the pacesetting projects from the past 170 years.