Between 2013 and February 2018, cumulative investment in construction technology totaled $18 billion, or double the amount invested during the previous five years.

A new analysis of the construction technology ecosystem by McKinsey & Co., the global management consulting firm, identifies where that investment is being directed, how the market is likely to evolve in the next few years, and how the construction and engineering industries can accelerate their transitions into a digital future.

McKinsey has expanded its study to include the entire asset life cycle across more than 2,400 technology solutions companies—from concept and feasibility, to design and engineering, preconstruction, construction, and operations and maintenance. In doing so, McKinsey identifies 38 “use cases” that are spurring the creation of new companies and attracting investment capital.

Among the key trends has been the emergence of constellations of solutions around established use cases. The most prominent include 3D printing, modularization, and robotics; digital twin technology; artificial intelligence (AI) and analytics; and supply chain optimization and marketplaces.

McKinsey sees all of these are being “poised to be transformational for the industry.” AI, in the form of machine learning, is gaining momentum as an overarching use case, particularly in reality capture. “Indeed, by applying machine learning to an ongoing project, schedules could be optimized to sequence tasks and hit target deadlines, and divergences from blueprints could be caught closer to real time and corrected,” the report’s authors write.

While the report foresees only modest market penetration in the immediate future, “the potential impact [of AI] is so large that the industry can no long afford to ignore it.”

As for 3D printing, modularization and robotics, McKinsey’s research finds that consistent use of these techniques, on projects where they are economically feasible, “could boost the sector’s productivity by five- to tenfold.”

In fact, one of the “most exciting” applications of digital twin technology invnolve the seamless integration of 3D models generated by drone imagery.

McKinsey is less sanguine about the near-term growth of supply-chain optimization and marketplaces, observing that it’s still “nascent and limited to North America.”

‘Cross-cutting’ technologies could soar

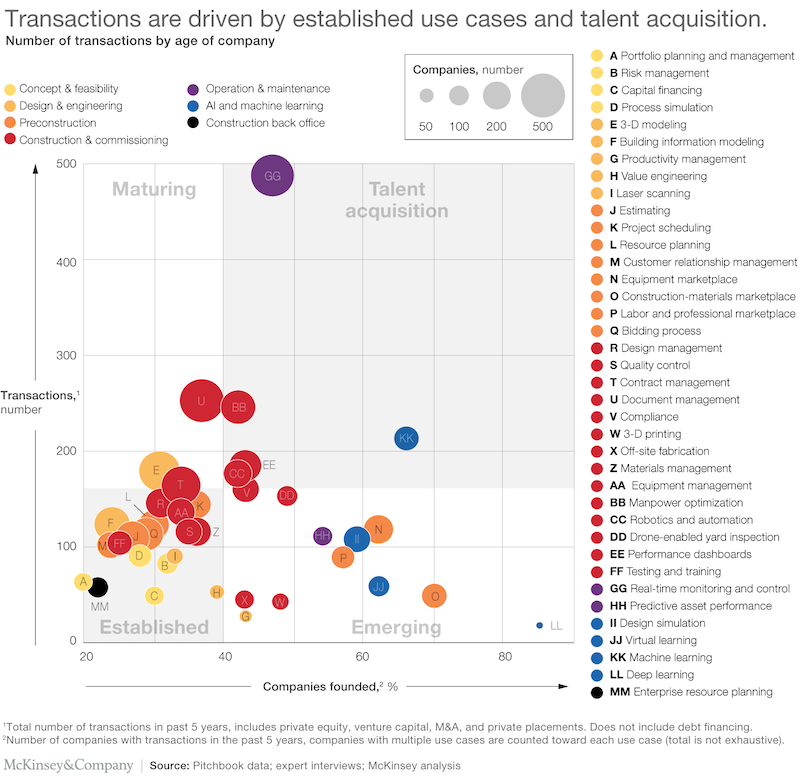

Over the past five years, investments into construction technology have fallen into four quadrants (see chart above), which McKinsey further breaks down by user cases to suggest where future opportunities might be most fertile. Image: McKinsey & Co.

From 2013 to early 2018, there were 908 investment transitions for construction technology, 75% of which involved early-stage venture capital. Late-stage VC was also on the rise, which McKinsey suggests indicated that certain use cases were ready for growth financing.

Construction remains the highest invested phase of the asset life cycle. It is also relatively mature; only one-third of companies in this phase are newcomers. Preconstruction and back-office phases are also garnering large investments.

McKinsey notes that “cross-cutting technologies” are gaining momentum because of their applicability across different stages of the life cycle. These include 3D printing, virtual learning, design simulation, machine learning, and deep learning. “The number of companies founded in this space over the past five years exceeds any other category, and the dollar value of transactions is quickly catching up with the rest of the categories,” the report states.

The report also cites two untapped markets: design/engineering, and concept/feasibility. There are various explanations for this, one being the office-based nature of these phases “means their relevant solutions (such as CAD or BIM) may already be relatively mature and sophisticated.”

Consolidation could spur investment

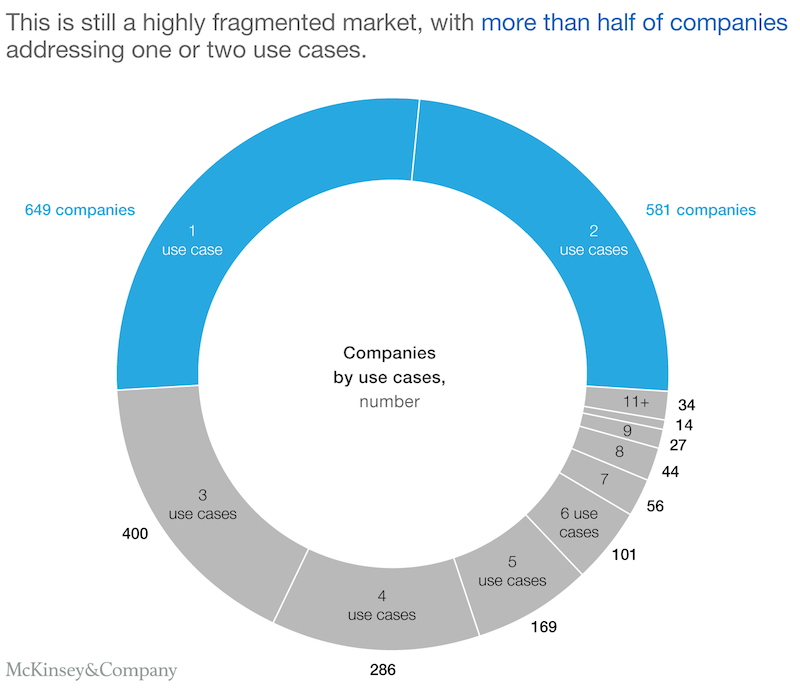

The report states that industry fragmentation is one of the biggest challenges for companies that want to engage with technology solutions. And the lack of use-case integration “is one of the drags on technology adoption at scale.” Consequently, more companies are exploring the potential to consolidation solutions that address multiple use cases.

The field of construction technology is still highly fragmented, and integration of technologies that can be integrated across different uses will present investment opportunities. Image: McKinsey & Co.

McKinsey offers its prescriptions for moving the industry quicker into a digital future, starting with investing in talent, which can increase the odds of digitization success by 2.5 times, the report estimates. Actively engaging with the start-up ecosystem and establishing conditions that make piloting and scaling more likely to succeed can also accelerate the industry’s transformation.

Tech providers need to listen closer to end users and adapt, and proactively plan for integration and consolidation. Owners should enforce a strong and sharable data foundation, align on supportive contract strategies, and identify and focus on critical user cases.

“Gone are the days when the construction industry can ignore the burgeoning set of technology solutions across the asset life cycle,” the report concludes. “We expect investment, competition, and consolidation to continue to accelerate, as use cases and start-ups serving the industry proliferate. As predictions come to life and new capabilities infiltrate the field, team, and office, the winners will be the ones that adapt—sooner rather than later.”

Related Stories

Wood | Nov 16, 2022

5 steps to using mass timber in multifamily housing

A design-assist approach can provide the most effective delivery method for multifamily housing projects using mass timber as the primary building element.

Giants 400 | Nov 14, 2022

4 emerging trends from BD+C's 2022 Giants 400 Report

Regenerative design, cognitive health, and jobsite robotics highlight the top trends from the 519 design and construction firms that participated in BD+C's 2022 Giants 400 Report.

Contractors | Nov 14, 2022

U.S. construction firms lean on technology to manage growth and weather the pandemic

In 2021, Gilbane Building Company and Nextera Robotics partnered in a joint venture to develop an artificial intelligence platform utilizing a fleet of autonomous mobile robots. The platform, dubbed Didge, is designed to automate construction management, maximize reliability and safety, and minimize operational costs. This was just one of myriad examples over the past 18 months of contractor giants turning to construction technology (ConTech) to gather jobsite data, manage workers and equipment, and smooth the construction process.

University Buildings | Nov 13, 2022

University of Washington opens mass timber business school building

Founders Hall at the University of Washington Foster School of Business, the first mass timber building at Seattle campus of Univ. of Washington, was recently completed. The 84,800-sf building creates a new hub for community, entrepreneurship, and innovation, according the project’s design architect LMN Architects.

Sponsored | Steel Buildings | Nov 7, 2022

Steel structures offer faster path to climate benefits

Faster delivery of buildings isn’t always associated with sustainability benefits or long-term value, but things are changing. An instructive case is in the development of steel structures that not only allow speedier erection times, but also can reduce embodied carbon and create durable, highly resilient building approaches.

Mass Timber | Aug 30, 2022

Mass timber construction in 2022: From fringe to mainstream

Two Timberlab executives discuss the market for mass timber construction and their company's marketing and manufacturing strategies. Sam Dicke, Business Development Manager, and Erica Spiritos, Director of Preconstruction, Timberlab, speak with BD+C's John Caulfield.

Green | Jul 26, 2022

Climate tech startup BlocPower looks to electrify, decarbonize the nation's buildings

The New York-based climate technology company electrifies and decarbonizes buildings—more than 1,200 of them so far.

Building Technology | Jun 9, 2022

GSA Green Proving Ground program selects six innovative building technologies for evaluation

The U.S. General Services Administration’s (GSA) Green Proving Ground program, in collaboration with the U.S. Department of Energy, has selected six innovative building technologies for evaluation in GSA’s inventory.

Smart Buildings | Jun 1, 2022

Taking full advantage of smart building technology

Drew Deatherage of Crux Solutions discusses where owners and AEC firms could do better at optimizing smart technology in building design and operations.

Sponsored | BD+C University Course | May 10, 2022

Designing smarter places of learning

This course explains the how structural steel building systems are suited to construction of education facilities.