For an Acid Tank Remodel project in Florida, a major chemical plant owner called upon the expertise of Moody Engineering, Inc. (MEI), a Florida-based group of consulting engineers that specializes in engineering and construction management design for commercial and industrial projects. With Moody’s ability to bring in their valuable experience with state-of-the-art 3D scanning and modeling technology, the Moody team was able to provide a practical scan-to-BIM solution. By integrating creativity and ingenuity with practicality, they were able to address the project’s specific requirements in order to save the customer time and money on this challenging project.

CHALLENGES

For the Acid Tank remodel project, Moody Engineering, Inc. was charged with the task of providing mechanical, structural, and piping design. The scope of the work on this project dictated that Moody replace the roof on this tank. The whole tank, in fact, was falling in on itself. The main challenges at the job site included: 1) scanning the inside of the acid tank and its exterior surroundings while the plant was still in operation, and 2) navigating the scanner through an industrial structure while getting the right scan locations.

Without use of the scanner, Moody’s engineers couldn’t have taken field measurements without extensive mobile and safety equipment (high reach, scaffolding, etc.). The reality is that the owner might have decided to scrap the tank altogether, an option that was discussed along the way: Replacing vs. modifying. Moody sought to determine if, based of what they were able to do with the point cloud and the scans, they would be able to salvage at least the wall of the tank—rebuild the tank as opposed to pulling everything out and putting a new tank in, which would have been much more expensive.

The answer was yes.

SOLUTION

Perhaps the biggest benefit for Moody using the FARO® 3D Focus Laser Scanner —and the reason they got the scanner in the first place—is safety. Scanning allowed them to reduce the number of people they had going out in the field, not to mention the fact that is reduces the likelihood that they’d need to send people back out since they would already have captured the required information in the scan. Scanning eliminated the need for a high reach and for the operator needing to do the work by hand.

Of course, the operating cost and time savings were among the other tangible benefits. A scan that takes 30 minutes might otherwise take them two or three days. For the scanning process itself, Moody only needed one or two people doing the work. If they missed a spot that had to be in the scan, the portability and the ability to quickly go out and take care of it made the scanner an invaluable tool. As Steve Moody, P.E., MEI’s President and Director of Engineering notes, “3D scanning eliminated fit-up errors at a plant-critical time for a plant-critical system.”

For this project, Moody went in several times to scan. The first time, they went in to scan the top of the tank to get all the equipment in order to ensure the equipment would ultimately be put back in the same spot when they generated the drawings from the scan. Because the severely poor condition of the tank, they didn’t want a lot of people up there pulling tape and doing field measurements so they decided to scan it to get in and out as quickly as they could and develop their 3D model from that.

About a week later, Moody went back and did the ground scan. They then merged the two scans together to create a complete model so that they would not have to be around the tank in its unsafe condition. One of the two scanning operators also scanned the inside as well. All in all, there were three different sets of scans merged together. Using traditional methods, there would have been no way to pull tape on every single piece of equipment, pipe, ad everything that was out there. The scanner not only made the most sense—but was really the only practical option—and allowed for the opportunity repair rather than replace the tank.

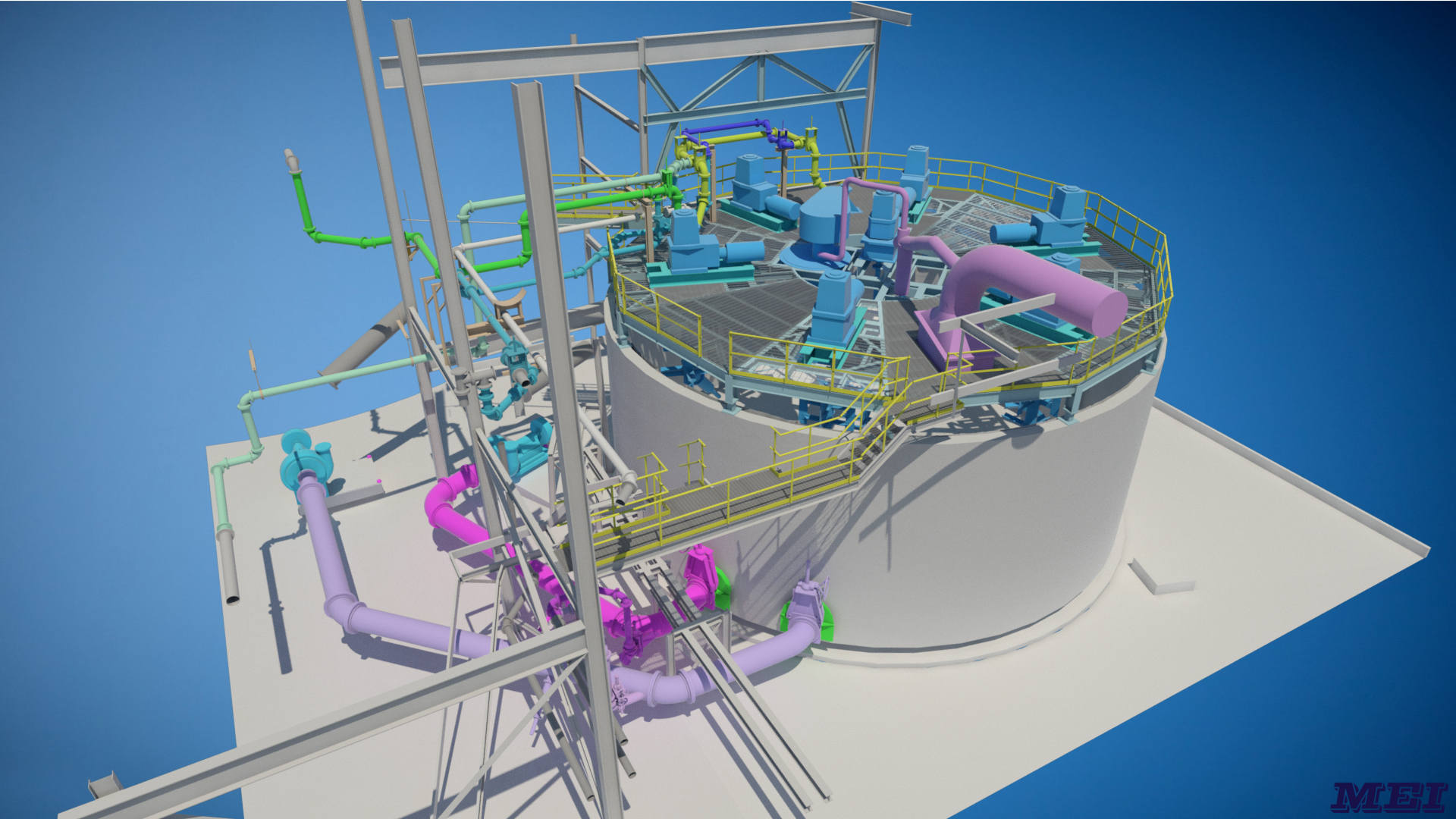

New reactor tank roof design model with optimized piping and equipment layout to allow for easier maintenance.

New reactor tank roof design model with optimized piping and equipment layout to allow for easier maintenance.

Workflow: Pre-Modeling

In terms of workflow particulars, Moody handled this job as they do on most jobs—they went in and walked the job down. Their engineers went with the PM to look at the job and see the challenges they would face, assess safety consideration and take pictures. They then came back and developed a plan of attack. The engineer set up the FARO Focus Laser Scanner in certain spots to make sure they could capture everything they needed, then figured out how they would actually do it by maximizing scanning and minimizing the time on site. Scanning time ran a total of about 25 hours, which is significantly better than bringing the whole crew out to the site.

The initial scan took only two days with a verification day. According to MEI engineers, without the scanner, it would have taken three people from six to nine days with multiple trips back and forth to get it done. This is because information gets lost when work is done manually. The scanner eliminates all the uncertainty—if scanned correctly, the team never has to take trips back to the site.

Additionally, had traditional methods been used on this particular job, Moody would have needed to take field measurements with tape measures, plumb-bobs, etc. Using the FARO FocusS 150 and 350 provided Moody with an “as-built” environment that the team was able to replicate in the 3D model, thereby eliminating the need for long hours of pain-staking field measurements.

Workflow: The Modeling Aspect

Once the scanning is done, the next part of the workflow is to register the scans, throw it into SCENE, spit out the .fls files, put them into EdgeWise, and then they can grab the pipe on its own. The engineer takes that information to model any structure needed for the job using the scan information to show everything pictorially not only in a 3D environment but also in ClearEdge3D EdgeWise to extract that existing steel and know where the interferences will be. Moody then finishes out the piping. MEI engineers acknowledge that it definitely helps to get an existing as-built condition with the scan, without which they wouldn’t know the details of what’s out there. They can then pull it into AutoCAD®, model that tank, and do an analysis on it. It’s not just to “see the pretty point cloud.” The engineers can use it for a lot of other things.

By using ClearEdge3D EdgeWise, Moody cut its 3D modeling time by at least 60 percent; AutoCAD Plant 3D provided the basis for the piping design for all of Moody’s piping runs.

As for the company’s success using the scanning technology, Steve Moody, P.E. explains, “The 3D scan and model lets us pull dimensions from my office rather than in the field. It eliminates any concern about fit-ups in the field during construction.”

RESULTS

Regarding deliverables, Moody ultimately provided the client (Mosaic) with 2D drawing documentation generated from a practical Navisworks 3D BIM model in order to facilitate the modification of the tank. Moody’s team kept Mosaic apprised all the way through, giving them models at various intervals so they could review it, rather than the old way of 2D drawings alone where you don’t know exactly what you’re looking at.

With a 3D model, you can spin it around, show the client the scans, and let them see in the point cloud how Moody was able to get around the interferences. Moody's engineers note, “Oftentimes, drawings are lacking and you have to make do. Without the scanner, we wouldn’t have anything. Having the scans is a huge advantage as sometimes 2D drawings do not provide correct or complete information.”

Estimated Cost and Time Savings

3D scanning greatly influenced the team’s strategy to repair the tank vs. replace-in-kind. The only real estate available for a new tank was far removed from the current tank location onsite. Consequently, the client would have had to endure the cost of not only building a new tank, but also the added high operations and capital expenses of piping the acid product to and from the remote location.

While an exact bottom line is difficult to say, the scanning technology undoubtedly allowed for substantial savings when you consider that the dollar value of the tank is in the multimillions—and not having to replace the acid tank may have saved the client anywhere from 50 to 90 percent TIC (total installed cost).

Additionally, the following assumptions can be made to help further quantify time and cost savings using scanning technology rather than traditional methods:

With 3D scanning:

- Two people for two 8-hr days: ~$4-5K

Without 3D scanning:

- Three people for six to nine days: ~$25-30K

- Equipment + Scaffolding: ~$6-15K

- Mileage + Travel time: ~$4-5K

Client Satisfaction

According to a client representative, “Feedback so far is everyone is very happy with the final product. I certainly appreciated the responsiveness of MEI to our requirements as they evolved—and particularly the exceptional efforts to adhere to our very tight schedule. We’re very thankful to the entire MEI team that worked on this project.”

CONCLUSION

With 3D Scanning technology, structures that would have normally been deemed unrepairable and previously demolished can now be modeled and engineered with precision. Embracing this technology has allowed us to become better, more creative engineers. We are now able to focus on the most value-added use of our time, and eliminate unnecessary costs.

Related Stories

| Jul 11, 2014

Are these LEGO-like blocks the future of construction?

Kite Bricks proposes a more efficient way of building with its newly developed Smart Bricks system.

| Jul 1, 2014

Hyper-speed rendering: How Gensler turns BIM models into beauty shots in seconds

In search of a fast rendering solution, Gensler looked to the gaming and moviemaking industries for the next breakthrough tool: Octane Render.

| Jul 1, 2014

Sochi's 'kinetic façade' may steal the show at the Winter Olympics

The temporary pavilion for Russian telecom operator MegaFon will be wrapped with a massive digital "pin screen" that will morph into the shape of any face.

| Jul 1, 2014

7 ways to cut waste in BIM implementation

Process mapping, split models, and streamlined coordination meetings are among the timesaving techniques AEC firms are employing to improve BIM/VDC workflows.

| Jun 30, 2014

Autodesk acquires design studio The Living, will create Autodesk Studio

The Living, David Benjamin's design studio, has been acquired by Autodesk. Combined, the two will create the Autodesk Studio, which will "create new types of buildings, public installations, prototypes and architectural environments."

| Jun 30, 2014

Report recommends making infrastructure upgrades a cabinet-level priority

The ASCE estimates that $3.6 trillion must be invested by 2020 to make critically needed upgrades and expansions of national infrastructure—and avoid trillions of dollars in lost business sales, exports, disposable income, and GDP.

| Jun 25, 2014

Taking a page from Lean manufacturing for improved design review processes

SPONSORED CONTENT As more building project teams look for ways to collaborate better, technology continues to provide solutions. Yet, as I learned from the experience of one of my customers, choosing the wrong technology can have an underwhelming effect, causing a team to simply swap out old challenges for new ones.

| Jun 18, 2014

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 10, 2014

Site optimization: Paving the way for smoother land development projects

The biggest cost differential when dealing in site development from one site to another is the earthwork. So, when selecting a site, it is critical to not only take into account the initial purchase price of the property, but also what sort of investment it will take to prep the site for development.

Smart Buildings | Jun 8, 2014

Big Data: How one city took control of its facility assets with data

Over the past few years, Buffalo has developed a cutting-edge facility management program to ensure it's utilizing its facilities and operations as efficiently, effectively, and sustainably as possible.