The work processes and roles of architects, engineers, and general contractors are continuing to be disrupted by building information modeling and virtual design and construction technologies. Three emerging innovations are representative of the radical change that’s taking place in the commercial construction market.

Model-based Visual Estimation Brings

Real-time Cost Estimating to the Design Phase

Kansas City, Mo.-based general contractor JE Dunn Construction had a great in-house estimating tool at its disposal. Comprising more than 30 years of estimating calculations complied by the firm’s VP of Estimating, Martin Blood, the ATSE system (short for Art To Science Estimating) gave JE Dunn the information and know-how to be able to estimate prices accurately very early in the design process.

ATSE’s pricing engine takes into account design decisions to make sure the contractor has the right price and the building will meet code requirements. It also understands how building systems work together and what impact different decisions have on the installation and operation of those systems.

There was just one problem: JE Dunn couldn’t get designers to use ATSE. They didn’t believe the tool could be that accurate at the conceptual design stage.

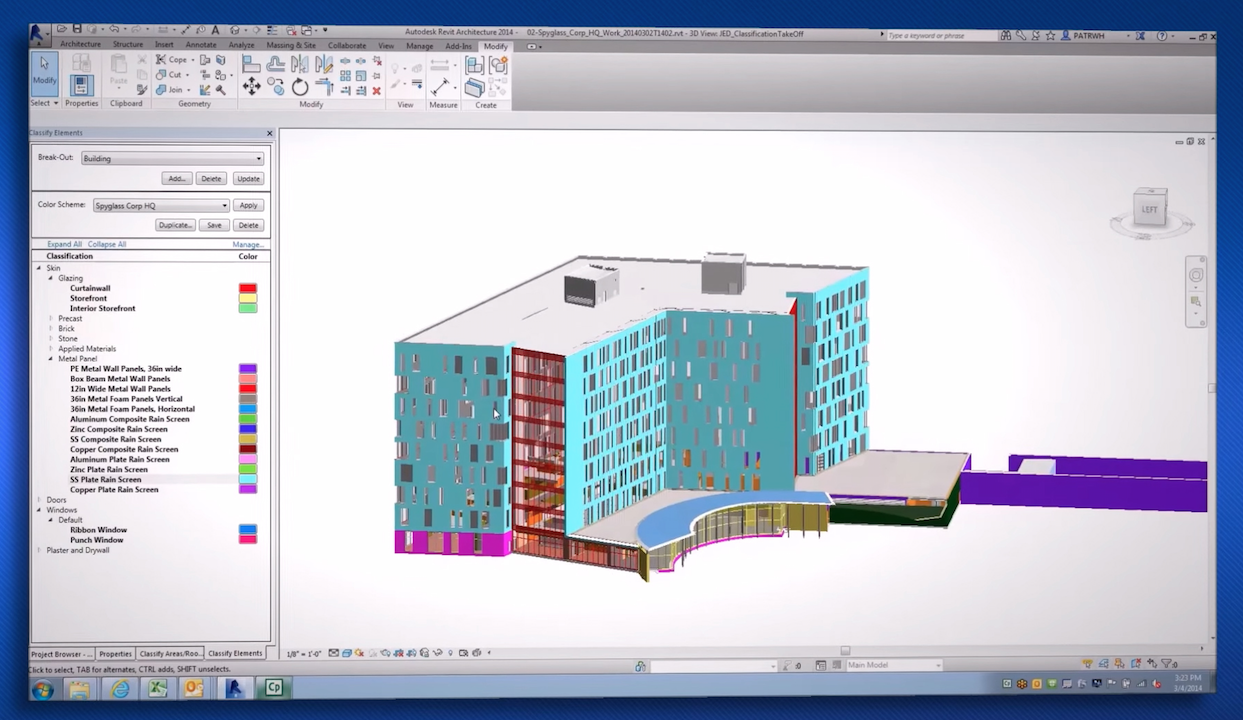

The new tool, JE Dunn Lens, creates a data layer on top of an architect’s BIM model to provide real-time cost estimates.

The new tool, JE Dunn Lens, creates a data layer on top of an architect’s BIM model to provide real-time cost estimates.

“It’s a complex system wherein a very minimal amount of design input leads to a series of trickle-down quantifications based on engineered formulas and, more importantly, on how full systems come together during construction,” says John Jacobs, JE Dunn’s CTO. He says, using ATSE, the firm is able to accurately price (within 5%) projects that are in the napkin-sketch stage. “People never believed this, so we added a visualization element to that pricing model.”

The new tool, JE Dunn Lens, deployed last year, creates a data layer on top of an architect’s BIM model to provide real-time cost estimates. If the design team, for example, adds a floor to the project or changes a piece of MEP equipment, the adjustments are represented in both the estimate and the visual model. The calculations built into the system pull accurate, local prevailing prices for construction products such as rebar and structural steel beams.

“When we can sit with a designer and have a verbal and visual conversation that immediately results in a budget adjustment, that fundamentally changes how a GC and an architect work together,” says Jacobs. “The designer can focus on the owner’s needs and doesn’t have to worry about translating every little detail to something that a GC can use so that they can have a reliable price.”

Lens is currently being used on more than 30 projects across the nation, representing some 300 estimates to date. On one project alone, it was used to deliver 24 estimates in 19 weeks.

Component-Based Structural System

Makes Steel Erection a Snap

ConXtech developed and manufactures a prefabricated, mass-customized, component-based structural steel moment frame and space frame building system. The company’s ConX System reduces the structural frame of a building to a robust “chassis,” made up of HSS or box columns (typically concrete filled), wide-flange beams, and patented interlocking joints. One joint forms a moment connection (a collar), and the other a gravity connection. Building Teams assemble the connections on site by lowering and locking them into place. The process requires virtually none of the “cut-and-fit” or welding that typically takes place in the field, according to the company’s Founder and CEO Bob Simmons.

“The weight and 3D taper of the structural pieces draws them into alignment, and holds them in place,” says Simmons. This design feature eliminates the need for a crane to hold structural members in place at a precise elevation before they are welded.

The ConXTech system is a moving chassis wherein one joint forms a moment connection, the other a gravity connection. Both connections are assembled by lowering and locking them into place. Courtesy ConXTech. Click photo to enlarge.

The ConXTech system is a moving chassis wherein one joint forms a moment connection, the other a gravity connection. Both connections are assembled by lowering and locking them into place. Courtesy ConXTech. Click photo to enlarge.

“Typically, the crane operator is engaged, holding it at elevation, while an ironworker is sticking a tapered pin in to hold it at alignment and then a bolt to fix it into place before welding,” Simmons explains. “Our system is intended to make the work more efficient and safer.”

ConXtech can take any 3D model, whether from a 3D BIM program or something as simple as 2D AutoCAD, import it into its ConXCAD application and convert the geometry into a set of wireframe parametric components, which will eventually be erected by the chassis system. The wireframe drives everything from manufacturing to installation. The time savings can be dramatic.

For example, a ConX steel frame and concrete-over-metal-deck structural system for Kaiser Permanente’s 64,700-sf, three-story medical office building in San Mateo, Calif., was fabricated and erected in less than eight weeks—four weeks for fabrication, six-and-a-half days for steel assembly, and three weeks to complete the deck. The process, led by DPR Construction, maximized full coordination with subcontractors.

“All buildings, when you’re framing, have columns and beams,” says Simmons. “We had to become more modular. The point was to use those interconnections. If we can use the extra capacity in the columns and beams and hook them together with a rigid connection, then we have a more efficient structural solution.”

Airbus Uses Generative Design and

3D Printing to Reinvent Airplane Interiors

David Benjamin, Principal with the design practice The Living, has been exploring generative design for years. The process employs computing power to generate, evaluate, and evolve thousands of design options that can meet the goals of the project. It also uncovers new design possibilities through the inherently iterative process.

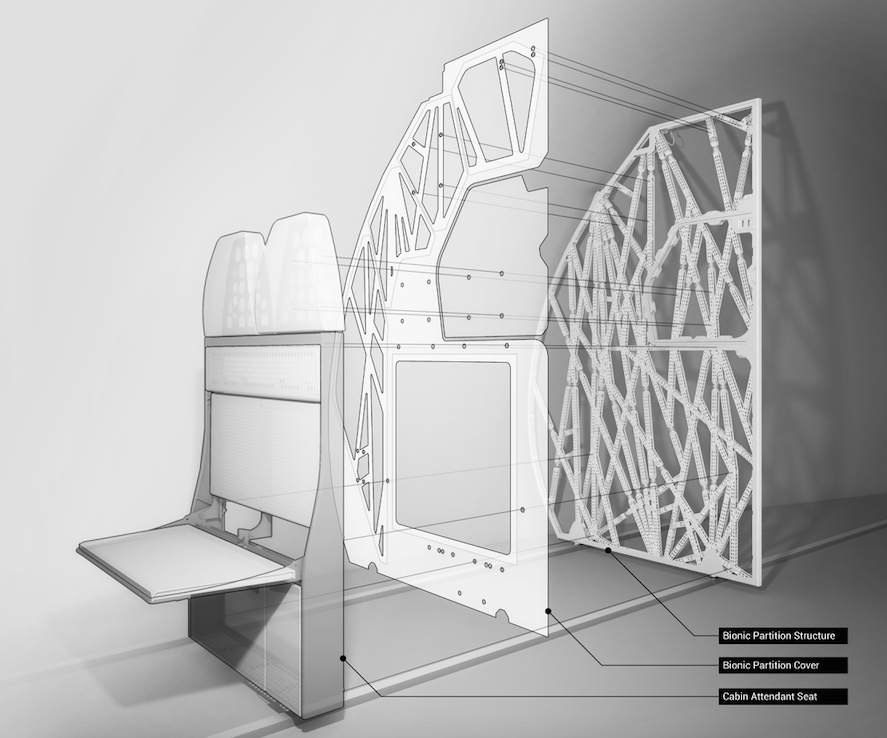

When aircraft giant Airbus saw some of Benjamin’s generative design work at the Autodesk Gallery in 2011, it started a multiyear project to create the first generatively designed aircraft partition for the Airbus A320.

The “bionic” partition is 3D-printed from a direct metal laser sintering (DMLS) printer that uses a new rare earth metal alloy, called scalmalloy, to achieve the lightness of aluminum with the strength of titanium.

The web-like partition is stronger and as much as 55 pounds lighter than current systems.

The web-like partition is stronger and as much as 55 pounds lighter than current systems.

Using the generative design process, Benjamin’s team developed a web-like partition that is stronger and as much as 55 pounds lighter than current systems. The design is incredibly efficient, using a minimal amount of the metal alloy. It’s also redundant: the structure can hold its own weight if one or more of the nodes are compromised. The 122 parts that make up the partition are printed in seven batches.

If the partition passes final testing, Airbus intends to install it in every new A320. Benjamin says the move will remove 96,000 tons of CO2 a year, thanks to less jet fuel being burned to transport the heavier legacy partitions.

“I think this was, in many ways, a demonstration project for advanced metal 3D printing as well as for generative design and its possibilities,” says Benjamin.

As manufacturing and building delivery draw ever closer, projects like this one, which utilize the latest advancements in computational design and 3D printing, show what’s possible for Building Teams that embrace the latest technologies.

Related Stories

BIM and Information Technology | Sep 7, 2016

Energy Star Portfolio Manager tool updated to factor in waste management

The costs and benefits of managing 29 types of waste are now included.

BIM and Information Technology | Aug 30, 2016

BIM GIANTS: A ranking of the nation's top BIM design and construction firms

HOK, Perkins+Will, Turner Construction Co., The Whiting-Turner Contracting Co., Jacobs, and Thornton Tomasetti top Building Design+Construction’s annual ranking of the nation’s largest BIM AEC firms, as reported in the 2016 Giants 300 Report.

BIM and Information Technology | Aug 30, 2016

New service from CBRE provides deeper insights into in-building wireless network experiences

With dependable cellular and Wi-Fi coverage a must-have amenity for today’s businesses, CBRE to certify in-building network quality through new Cellular Signal Mapping service

BIM and Information Technology | Aug 22, 2016

The wicked problem of interoperability

Building professionals are often put in a situation where solving problems with the ‘best tool for the job’ comes at the cost of not being able to fully leverage data downstream without limitation, writes Proving Ground's Nathan Miller.

Contractors | Aug 10, 2016

Dodge launches new app to simplify pros' search for suitable projects to bid and work on

The product, called PlanRoom, could be particularly useful in sharing data and communications among AEC teams.

BIM and Information Technology | Aug 9, 2016

How to improve a project presentation with animated GIFs

Animated GIFs are a simple tool that can explain a large amount of intricate information in an easy to understand, streamlined manner.

BIM and Information Technology | Jul 25, 2016

Autodesk’s LIVE turns designs into video game-like experiences

Users can adjust navigation points, render styles, and even the time of day, with fluid and quick controls.

Building Tech | Jul 14, 2016

Delegates attending political conventions shouldn’t need to ask ‘Can you hear me now?’

Each venue is equipped with DAS technology that extends the building’s wireless coverage.

BIM and Information Technology | Jun 14, 2016

Autodesk and Trimble will share APIs to develop products that improve user workflow

Data and document management is likely to benefit the soonest.

BIM and Information Technology | Jun 13, 2016

The race to digitize the globe with 3D imagery

Tech firms are creating a highly-detailed virtual planet available instantly for those who would like to scrutinize it. SmithGroupJJR's Stephen Conschafter details the new technologies being used to map our world.