Back in 2009, BD+C wrote about HKS licensing Epic Games’ Unreal Engine to create a virtual reality environment that could show clients completely rendered views and game-day experiences at the newly christened Dallas Cowboys Stadium (now called AT&T Stadium).

Much has changed in the last six years in the virtual augmented reality world. A half-decade ago, VR was not a consumer product. Creating a VR experience required deep pockets and the help of specialized production companies, such as Epic Games, to build the models. Now, immersive 3D headsets such as Oculus’s Rift 3D are available to consumers for a few hundred bucks, and gaming engines like Unity are available for free, online.

AEC teams are using gaming engines to not just showcase their projects, but to immerse their clients, end users, and Building Team members in highly detailed, fully lit environments that simulate the final structure. VR has advanced from a novelty technology for basic walkthroughs to a true, proof-of-concept tool.

To get a sense of how AEC firms are using VR, let’s explore a couple of recent applications.

gaming a high-tech lab project

Located in Kendall Square, a biotech-oriented R&D business district in Cambridge, Mass., 75/125 Binney Street is a large-scale, high-tech laboratory project encompassing three buildings with a connecting atrium. Ariad Pharmaceuticals’ new corporate headquarters and lab complex is the anchor tenant.

The 382,000-sf business park was designed and built using a highly collaborative delivery approach. Construction manager Gilbane Building Co. and architect Payette co-located their teams—along with the project’s mechanical, electrical, plumbing, fire sprinkler, structural steel, and exterior skin trade contractors—to solve the many complex issues that arose during the project.

The five-story atrium posed a number of thorny problems. Designed to function as a vast pocket park in a beehive of activity between the adjacent buildings, the atrium is as much public art as it is connective event space, according to Payette. A dramatic three-story, steel-and-thermoformed-plastic spiral staircase is the centerpiece of the public space. It also features a series of structural “asparagus”—stainless steel mesh supports for artistic metal vines— throughout the glass-enclosed atrium.

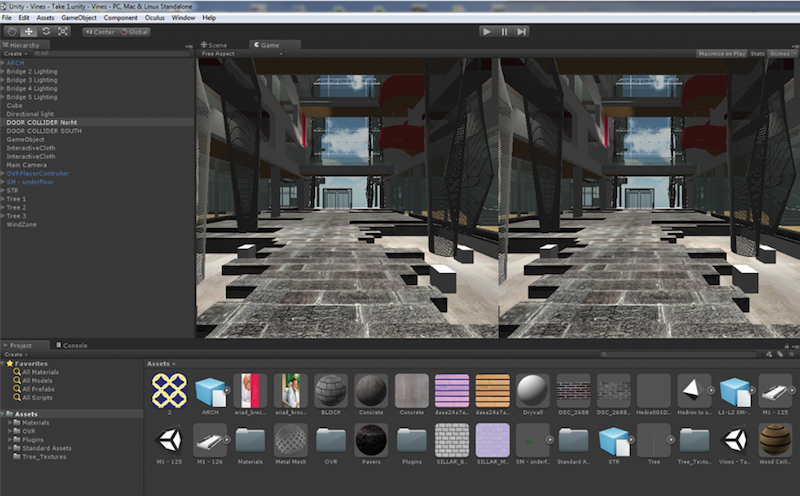

The Unity editing program was used to automate the conversion of the BIM model to the Unity gaming engine on the 75/125 Binney Street project.

The Unity editing program was used to automate the conversion of the BIM model to the Unity gaming engine on the 75/125 Binney Street project.

Creating a physical mockup of the asparagus and the staircase in the space was impossible because, due to a tight construction schedule, the atrium was already filled with scaffolding to support work on other parts of the project.

“The architect was still working with the owner to develop the feel of the space while we were putting scaffolding up,” says John Myers, Senior Virtual Design and Construction Engineer at Gilbane. “We even had 3D sections as part of our drawing set, and it was still difficult for our stakeholders to look at those and understand how the space would be built and how it would feel when it was done.”

The Gilbane team questioned whether the space could physically accommodate all 12 of the asparagus structures called for in the original design.

Myers had purchased an Oculus Rift headset at the beginning of the project, and had used Unity on other projects. His team converted the project’s Revit model to a Unity model and showed the architects and owners what the space would look like with six asparagus configurations rather than 12.

“We said, as the CM, ‘Guys, this might get a little bit cluttered,’” says Myers. “By understanding the scale of the other atrium elements, using virtual reality, we argued for only six.”

The design further called for the bottom encasement of the staircase to be a linear wood soffit. The construction team believed the finish would have been cost-prohibitive, labor-intensive, and incredibly difficult to execute.

“The underside of the staircase was one big Unity item, and the structural asparagus were another one,” says Myers. “In both situations we were able to come to a resolution that was good for the owner, good for the architect, and good for Gilbane. If all you had was a 3D rendering to go on, you couldn’t understand that space.”

Converting the BIM model to the Unity environment was not easy, says Myers. In gaming engines, two triangles are created to represent every visible square. Every solid will have six times as many triangles, or polygons. This is why the early Dire Straits 3D video is so blocky: low polygon count in a pre-mesh era.

“You’re talking millions of triangles,” says Myers. “We tried to limit it to the areas that are necessary. The atrium came about as part of a change order. We had a $20 million change order, and it was done the right way.”

Since Gilbane’s work on 75/125 Binney Street, the firm has expanded its use of gaming engines to include Unreal Engine, Unity, and the Oculus Rift.

VIRTUAL REALITY at the VCU HEALTH SYSTEM

DPR Construction was confronted with an unusual set of circumstances on the renovation of the 85,000-sf Virginia Commonwealth University Health System’s main hospital, in Richmond, which is scheduled for completion in early 2018.

The main floor of the hospital required 18 new operating rooms, an MRI suite, a pre- and post-operative care unit, an expanded waiting and reception area, and associated support spaces. The multi-phase project required the hospital to remain open during the renovation.

Space constraints in the jam-packed hospital precluded the use of physical mockups to show the planned changes to doctors, nurses, hospital administrators, and other stakeholders. Worse yet, there wasn’t ample room within walking distance of the campus or neighboring office buildings to set up a VR CAVE environment. The goal was to get as many end users through the BIM model as possible, but traveling off campus was not a realistic option.

After demoing the Oculus Rift early in the project, Michael Fievet, Senior Project Manager for owner’s representative JLL, suggested the team explore leveraging the technology to provide virtual mockups.

“A big advantage [of the Oculus Rift] is its portability,” says Justin Schmidt, BIM Manager at DPR. “Using a setup that can fit inside a backpack, clients can see their work environment in a photorealistic world.”

The Building Team, including architect HKS, was quickly on board, and detailed virtual mockups were created. Using the Oculus Rift, the team was able to address common questions: Where is the light coming from? How will it impact the space? How much space will I have around me to do my work? Such information is difficult to convey with a typical BIM model scenario, even with CAVEs and fly-throughs in translators such as Navisworks.

Ultimately, the project team was able to walk nearly 40 hospital employees through the mockup, while spending a fraction of the project’s original mockup budget.

DPR’s Schmidt says the move from BIM to VR raises a number of problematic issues for Building Teams. “Currently, our BIM models are not constructed to be optimized in a virtual reality environment,” he says. “The more you model, the slower your computer performs.”

The solution, says Schmidt, requires a combination of remodeling certain components while using texture maps to convey details that do not need to be modeled.

Since DPR’s use of VR on the VCU hospital project, there have been a number of hardware and software improvements that make the technology more accessible to AEC teams. These include software that directly interfaces with Revit to simplify the conversion process, says Schmidt.

“Two years ago, it was a manual process: export from Revit to 3ds Max, optimize, bring it into Unity, add special plug-ins to make it work, and then take it to Oculus,” he says. “Now it’s almost as easy as pressing a button, thanks to software automating those processes.”

Related Stories

| Nov 16, 2010

Calculating office building performance? Yep, there’s an app for that

123 Zero build is a free tool for calculating the performance of a market-ready carbon-neutral office building design. The app estimates the discounted payback for constructing a zero emissions office building in any U.S. location, including the investment needed for photovoltaics to offset annual carbon emissions, payback calculations, estimated first costs for a highly energy efficient building, photovoltaic costs, discount rates, and user-specified fuel escalation rates.

| Nov 9, 2010

12 incredible objects being made with 3D printers today

BD+C has reported on how 3D printers are attracting the attention of AEC firms. Now you can see how other creative types are utilizing this fascinating printing technology. Among the printed items: King Tut’s remains, designer shoes, and the world’s smallest Rubik’s Cube.

| Nov 5, 2010

New Millennium’s Gary Heasley on BIM, LEED, and the nonresidential market

Gary Heasley, president of New Millennium Building Systems, Fort Wayne, Ind., and EVP of its parent company, Steel Dynamics, Inc., tells BD+C’s Robert Cassidy about the Steel Joist Manufacturer’s westward expansion, its push to create BIM tools for its products, LEED, and the outlook for the nonresidential construction market.

| Nov 2, 2010

Energy Analysis No Longer a Luxury

Back in the halcyon days of 2006, energy analysis of building design and performance was a luxury. Sure, many forward-thinking AEC firms ran their designs through services such as Autodesk’s Green Building Studio and IES’s Virtual Environment, and some facility managers used Honeywell’s Energy Manager and other monitoring software. Today, however, knowing exactly how much energy your building will produce and use is survival of the fittest as energy costs and green design requirements demand precision.

| Oct 13, 2010

Test run on the HP Z200 SFF Good Value in a Small Package

Contributing Editor Jeff Yoders tests a new small-form factor, workstation-class desktop in Hewlett-Packard’s line that combines performance of its minitower machine with a smaller chassis and a lower price.

| Oct 13, 2010

Prefab Trailblazer

The $137 million, 12-story, 500,000-sf Miami Valley Hospital cardiac center, Dayton, Ohio, is the first major hospital project in the U.S. to have made extensive use of prefabricated components in its design and construction.