A growing number of firms, including HDR, NBBJ, and Thornton Tomasetti, are investing in talent and training to advance their computational design capabilities. Here’s a roundup of the clever applications for CD:

1. Rapid prototyping. Why design a few prototypes when you can create thousands to find the ideal solution? Algorithm-based design processes allow teams to develop and explore dozens, even hundreds, of prototypes in a matter of hours—something that would be impossible using traditional methods.

2. Rapid iteration. Similarly, computational design is being used to more efficiently test and refine particular design schemes through rapid iteration—design, test, refine, repeat, in quick succession.

3. Data dashboards. Data can be an incredibly helpful resource for Building Teams, especially if it’s readily accessible and real time. Progressive firms are using CD methods to extract vital data from, for example, BIM models to feed custom Excel dashboards. Other firms are investing in more scalable platforms, such as Web-based data visualization, to gain insight into their data.

4. Automating repetitive duties. From mundane tasks like renaming files to complex projects like calculating the walking steps in a hospital floor plan, computational design tools can be used to automate the grunt work in the design process.

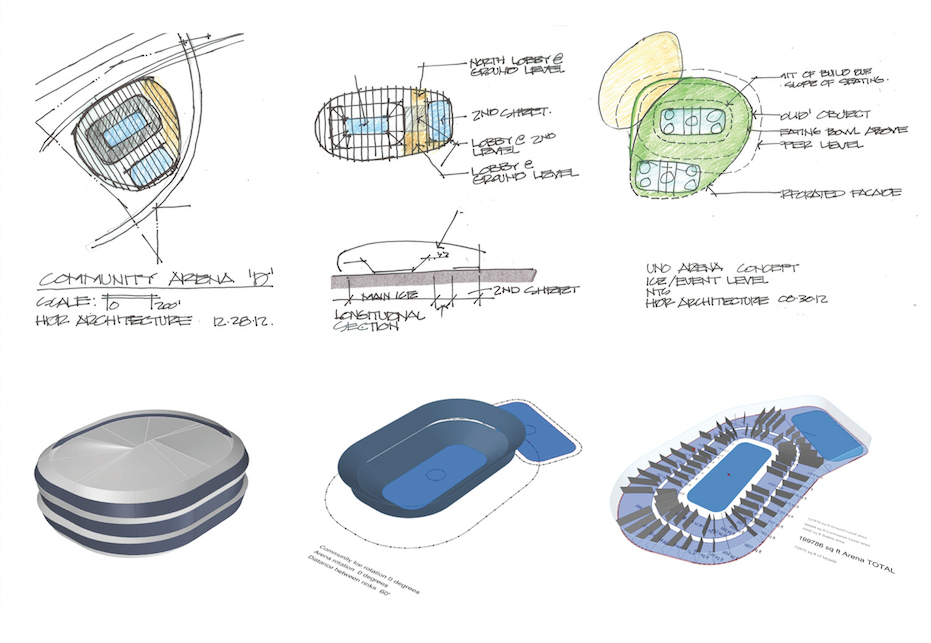

Using computational design tools, a team at HDR created an iterative process for building on-the-fly parametric models directly from sketches.

Using computational design tools, a team at HDR created an iterative process for building on-the-fly parametric models directly from sketches.

5. Creating custom plug-ins for existing software platforms. Need a tool that doesn’t exist on the market? No problem. Just code a solution. An extreme example is Thornton Tomasetti’s TTX database, which provides real-time read, write, and sync capabilities across six software tools: ETABS, Grasshopper, RAM Structural System, Revit, SAP 2000, and Tekla.

6. Evaluating the performance of early design concepts. Energy analysis, daylight modeling, even cost and schedule impacts—CD tools allow teams to make informed decisions much earlier in the design process.

For more on computational design, see BD+C's feature story, “Conquer computational design: 5 tips for starting your journey.”

Related Stories

Transportation & Parking Facilities | Aug 23, 2023

California parking garage features wind-activated moving mural

A massive, colorful, moving mural creatively conceals a newly opened parking garage for a global technology company in Mountain View, Calif.

Digital Twin | Jul 31, 2023

Creating the foundation for a Digital Twin

Aligning the BIM model with the owner’s asset management system is the crucial first step in creating a Digital Twin. By following these guidelines, organizations can harness the power of Digital Twins to optimize facility management, maintenance planning, and decision-making throughout the building’s lifecycle.

Designers | Jul 25, 2023

The latest 'five in focus' healthcare interior design trends

HMC Architects’ Five in Focus blog series explores the latest trends, ideas, and innovations shaping the future of healthcare design.

Digital Twin | Jul 17, 2023

Unlocking the power of digital twins: Maximizing success with OKRs

To effectively capitalize on digital twin technology, owners can align their efforts using objectives and key results (OKRs).

Standards | Jun 26, 2023

New Wi-Fi standard boosts indoor navigation, tracking accuracy in buildings

The recently released Wi-Fi standard, IEEE 802.11az enables more refined and accurate indoor location capabilities. As technology manufacturers incorporate the new standard in various devices, it will enable buildings, including malls, arenas, and stadiums, to provide new wayfinding and tracking features.

Virtual Reality | Jun 16, 2023

Can a VR-enabled AEC Firm transform building projects?

With the aid of virtual reality and 3D visualization technologies, designers, consultants, and their clients can envision a place as though the project were in a later stage.

AEC Innovators | Jun 15, 2023

Rogers-O'Brien Construction pilots wearables to reduce heat-related injuries on jobsites

Rogers-O'Brien Construction (RO) has launched a pilot program utilizing SafeGuard, a safety-as-a-service platform for real-time health and safety risk assessment. Non-invasive wearables connected to SafeGuard continuously monitor personnel to prevent heat exhaustion on jobsites, reducing the risk of related injuries. RO is the first general contractor to pilot this program.

Contractors | May 26, 2023

Enhanced use of data is crucial for improving construction job site safety

Executives with major construction companies say new digital tools are allowing them to use data more effectively to reduce serious safety incidents and improve job site safety.

AEC Tech Innovation | May 12, 2023

Meet Diverge, Hensel Phelps' new ConTech investment company

Thai Nguyen, Director of Innovation with Hensel Phelps, discusses the construction giant's new startup investment platform, Diverge.

AEC Tech | May 9, 2023

4 insights on building product manufacturers getting ‘smart’

Overall, half of building product manufacturers plan to invest in one or more areas of technology in the next three years.