A growing number of firms, including HDR, NBBJ, and Thornton Tomasetti, are investing in talent and training to advance their computational design capabilities. Here’s a roundup of the clever applications for CD:

1. Rapid prototyping. Why design a few prototypes when you can create thousands to find the ideal solution? Algorithm-based design processes allow teams to develop and explore dozens, even hundreds, of prototypes in a matter of hours—something that would be impossible using traditional methods.

2. Rapid iteration. Similarly, computational design is being used to more efficiently test and refine particular design schemes through rapid iteration—design, test, refine, repeat, in quick succession.

3. Data dashboards. Data can be an incredibly helpful resource for Building Teams, especially if it’s readily accessible and real time. Progressive firms are using CD methods to extract vital data from, for example, BIM models to feed custom Excel dashboards. Other firms are investing in more scalable platforms, such as Web-based data visualization, to gain insight into their data.

4. Automating repetitive duties. From mundane tasks like renaming files to complex projects like calculating the walking steps in a hospital floor plan, computational design tools can be used to automate the grunt work in the design process.

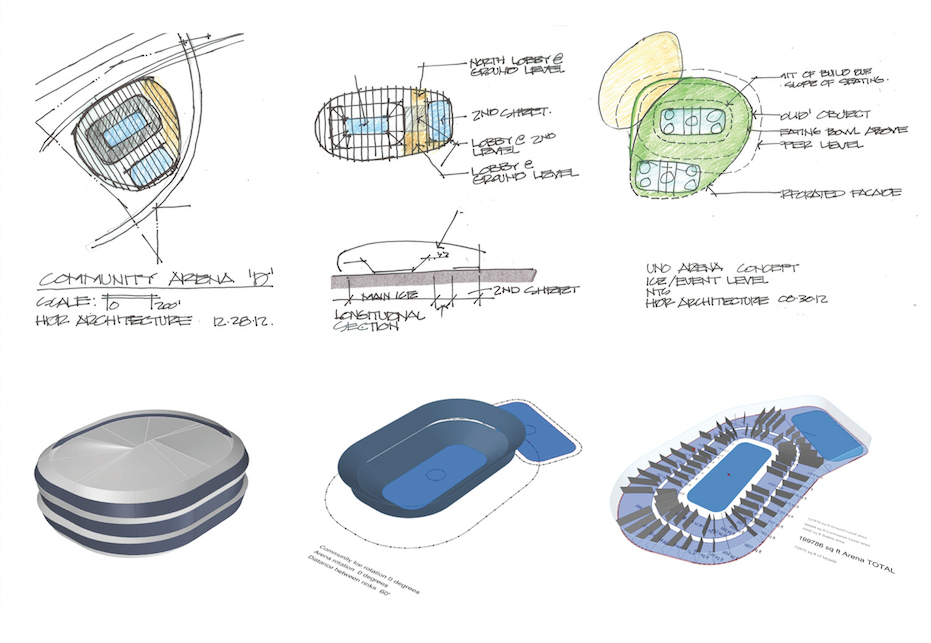

Using computational design tools, a team at HDR created an iterative process for building on-the-fly parametric models directly from sketches.

Using computational design tools, a team at HDR created an iterative process for building on-the-fly parametric models directly from sketches.

5. Creating custom plug-ins for existing software platforms. Need a tool that doesn’t exist on the market? No problem. Just code a solution. An extreme example is Thornton Tomasetti’s TTX database, which provides real-time read, write, and sync capabilities across six software tools: ETABS, Grasshopper, RAM Structural System, Revit, SAP 2000, and Tekla.

6. Evaluating the performance of early design concepts. Energy analysis, daylight modeling, even cost and schedule impacts—CD tools allow teams to make informed decisions much earlier in the design process.

For more on computational design, see BD+C's feature story, “Conquer computational design: 5 tips for starting your journey.”

Related Stories

AEC Tech | Jan 27, 2023

Epic Games' latest foray into the AEC market and real estate industry

From architecture to real estate, the realm of computer-aided design hits new heights as more and more firms utilize the power of Epic Games’ Twinmotion and Unreal Engine.

AEC Tech | Jan 27, 2023

Key takeaways from Autodesk University 2022

Autodesk laid out its long-term vision to drive digital collaboration through cloud-based solutions and emphasized the importance of connecting people, processes and data.

AEC Tech Innovation | Jan 24, 2023

ConTech investment weathered last year’s shaky economy

Investment in construction technology (ConTech) hit $5.38 billion last year (less than a 1% falloff compared to 2021) from 228 deals, according to CEMEX Ventures’ estimates. The firm announced its top 50 construction technology startups of 2023.

AEC Tech | Jan 19, 2023

Data-informed design, with Josh Fritz of LEO A DALY

Joshua Fritz, Leo A Daly's first Data Scientist, discusses how information analysis can improve building project outcomes.

AEC Tech Innovation | Jan 14, 2023

CES recognizes a Dutch firm’s wearable technology for construction management

The firm’s TokenMe product offers construction managers a real-time crowd- and asset-tracking solution via low-power, location-aware radio and RFID tags and multiple sensors through which data are processed with cloud-based artificial intelligence.

Digital Twin | Nov 21, 2022

An inside look at the airport industry's plan to develop a digital twin guidebook

Zoë Fisher, AIA explores how design strategies are changing the way we deliver and design projects in the post-pandemic world.

Giants 400 | Nov 14, 2022

4 emerging trends from BD+C's 2022 Giants 400 Report

Regenerative design, cognitive health, and jobsite robotics highlight the top trends from the 519 design and construction firms that participated in BD+C's 2022 Giants 400 Report.

Contractors | Nov 14, 2022

U.S. construction firms lean on technology to manage growth and weather the pandemic

In 2021, Gilbane Building Company and Nextera Robotics partnered in a joint venture to develop an artificial intelligence platform utilizing a fleet of autonomous mobile robots. The platform, dubbed Didge, is designed to automate construction management, maximize reliability and safety, and minimize operational costs. This was just one of myriad examples over the past 18 months of contractor giants turning to construction technology (ConTech) to gather jobsite data, manage workers and equipment, and smooth the construction process.

BAS and Security | Oct 19, 2022

The biggest cybersecurity threats in commercial real estate, and how to mitigate them

Coleman Wolf, Senior Security Systems Consultant with global engineering firm ESD, outlines the top-three cybersecurity threats to commercial and institutional building owners and property managers, and offers advice on how to deter and defend against hackers.

Webinar | Oct 6, 2022

Register today! Live webinar: The future of 3D + 360° construction progress management

Learn about the value of digital site documentation and progress monitoring, how reality capture is used for site documentation, and the value of both 3D scans and 360 photos. This live webinar will take place Thursday, October 20 at 2 ET/ 1 CT.