A few months ago, the world’s first self-described “Marschitect” was working on developing architecture designed specifically to meet the challenges of living on Mars. Now, more and more architects and researchers are taking a shot at developing new and innovative ways for building habitable environments on the surface of the inhospitable planet.

Two of the most recent ideas for potential building materials come from NASA researchers and a team of scientists at Illinois’s Northwestern University.

As Occam’s razor states, the simplest solution is usually the right one, and NASA researchers have taken that idea to heart as they believe the building material that may help solve many of the problems associated with living and building on Mars is regular, everyday ice, csmonitor.com reports.

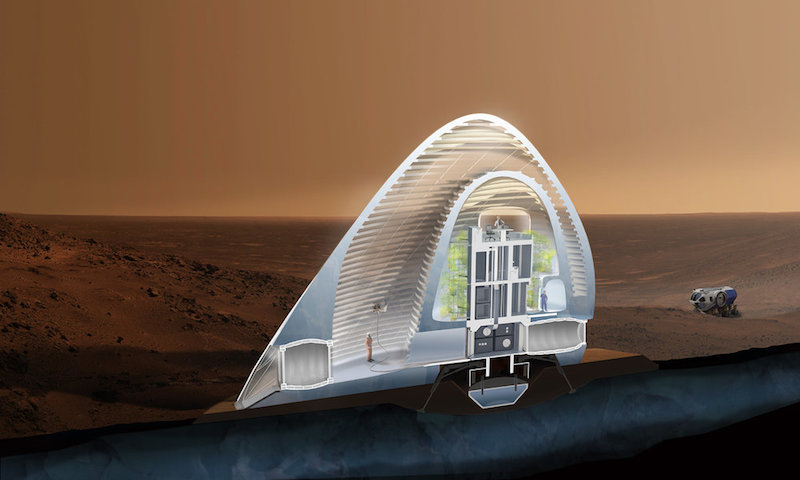

NASA’s Langley Research Center in Hampton, Va., recently revealed its design concept for the “Mars Ice Home,” which was developed with help from Space Exploration Architecture and the Clouds Architecture Office.

An inflatable inner-tube-like material would provide the actual living quarters for the astronauts while its exterior would be encased in a shell of 3D-printed ice. The ice would protect the structure, and those living within it, from cosmic rays, which are one of the biggest health concerns associated with humans living on Mars. While the ice structure would block the cosmic rays, it would still allow some light to pass through so it would more closely resemble living in a home than a cave or underground and allowing the astronauts to stay connected to natural diurnal cycles.

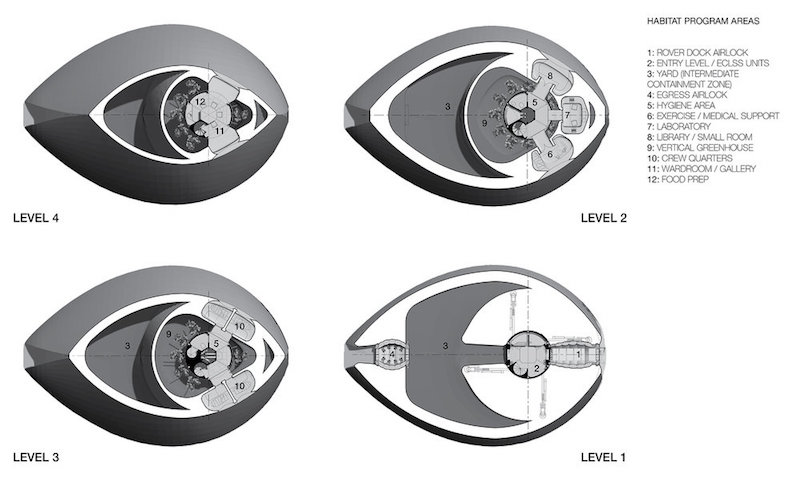

Cross section of the Mars Ice House. Courtesy of Space Exploration Architecture.

Cross section of the Mars Ice House. Courtesy of Space Exploration Architecture.

The ice shell would be five centimeters thick and is envisioned as a series of nested domes enclosed by a transparent ETFE (Ethylene tetrafluoroethylene) membrane. The outer shell creates a “front yard” that astronauts can occupy without the use of an EVA suit. The inner shell will provide a vertical hydroponic greenhouse that surrounds the inhabitants.

The Mars Ice House would be constructed without the need of a crew being present. The module would descend to the planet’s surface and land. Then the construction process would begin: the foundation is sintered, the ETFE membrane is inflated, the airlocks are deployed, the ice for the outer and inner shells is printed, and the plant-growing process beings. Only after all of this occurs does the crew arrive.

Since one of the biggest hurdles to building on Mars revolves around transporting any possible building materials to the planet, the lightness of the inflatable structure and the availability of ice on Mars make the Mars Ice Home a very intriguing possibility.

Courtesy of Space Exploration Architecture.

Courtesy of Space Exploration Architecture.

Another proposal for building on Mars uses the planets limited resources, as well, but instead of ice, a team of scientists from Northwestern University developed a form of “Martin concrete” that can be created using soil from the Red Planet, Dezeen reports.

The concrete is created by mixing the soil with molten sulfur and, according to the scientists, could be used to build entire villages on Mars. Most importantly, the concrete doesn’t require any water to make. The building material can endure low temperatures, is resistant to acid and salt, and can be melted down and recycled to build a different structure.

The idea of using the soil found on Mars to create a building material is not a new one. Foster + Partners created a concept for a 3D-printed habitat built by robots that uses regolith, loose soil, and rocks as the building materials, but according to Dezeen, this is the first time a report has detailed how this could actually be feasible.

After a series of trial and error experiments, the team, consisting of Lin Wan, Roman Wendner, and Gianluca Cusatis, determined an even mix of sulfur and aggregate would produce a material with a strength of 50 megapascals. When the difference of gravity on the surface of Mars is factored in, the material will be three times stronger, making it suitable for building on Mars.

The time it takes to travel to Mars makes the necessity of building a habitat for the astronauts on its surface unavoidable. While the development of Martian architecture may seem like nothing more than an exercise in creativity, it is actually an integral part of one day setting foot on Mars.

The "front yard" of the Mars Ice House. Courtesy of Space Exploration Architecture.

The "front yard" of the Mars Ice House. Courtesy of Space Exploration Architecture.

Foster + Partners' 3D-printed proposal. Courtesy of Foster + Partners.

Foster + Partners' 3D-printed proposal. Courtesy of Foster + Partners.

Related Stories

| Feb 1, 2012

Two new research buildings dedicated at the University of South Carolina

The two buildings add 208,000 square feet of collaborative research space to the campus.

| Jan 31, 2012

AIA CONTINUING EDUCATION: Reroofing primer, in-depth advice from the experts

Earn 1.0 AIA/CES learning units by studying this article and successfully completing the online exam.

| Jan 26, 2012

American Standard names Gould as president and CEO

Gould succeeds Don Devine, who led the successful turnaround of American Standard Brands.

| Jan 15, 2012

Hollister Construction Services oversees interior office fit-out for Harding Loevner

The work includes constructing open space areas, new conference, trading and training rooms, along with multiple kitchenettes.

| Jan 12, 2012

3M takes part in Better Buildings Challenge

As a partner in the challenge, 3M has committed to reduce energy use by 25% in 78 of its plants, encompassing nearly 38 million-sf of building space.

| Jan 9, 2012

METALCON International 2012 announced

METALCON 2012 is scheduled for Oct. 9-11 at the Donald E Stephens Convention Center, Hall A, Rosemont, Ill.

| Jan 6, 2012

New Walgreen's represents an architectural departure

The structure's exterior is a major departure from the corporate image of a traditional Walgreens design.

| Jan 4, 2012

New LEED Silver complex provides space for education and research

The academic-style facility supports education/training and research functions, and contains classrooms, auditoriums, laboratories, administrative offices and library facilities, as well as spaces for operating highly sophisticated training equipment.

| Jan 3, 2012

BIM: not just for new buildings

Ohio State University Medical Center is converting 55 Medical Center buildings from AutoCAD to BIM to improve quality and speed of decision making related to facility use, renovations, maintenance, and more.

| Jan 3, 2012

New SJI Rule on Steel Joists

A new rule from the Steel Joist Institute clarifies when local reinforcement of joists is required for chord loads away from panel points. SJI members offer guidance about how and when to specify loads.