A few months ago, the world’s first self-described “Marschitect” was working on developing architecture designed specifically to meet the challenges of living on Mars. Now, more and more architects and researchers are taking a shot at developing new and innovative ways for building habitable environments on the surface of the inhospitable planet.

Two of the most recent ideas for potential building materials come from NASA researchers and a team of scientists at Illinois’s Northwestern University.

As Occam’s razor states, the simplest solution is usually the right one, and NASA researchers have taken that idea to heart as they believe the building material that may help solve many of the problems associated with living and building on Mars is regular, everyday ice, csmonitor.com reports.

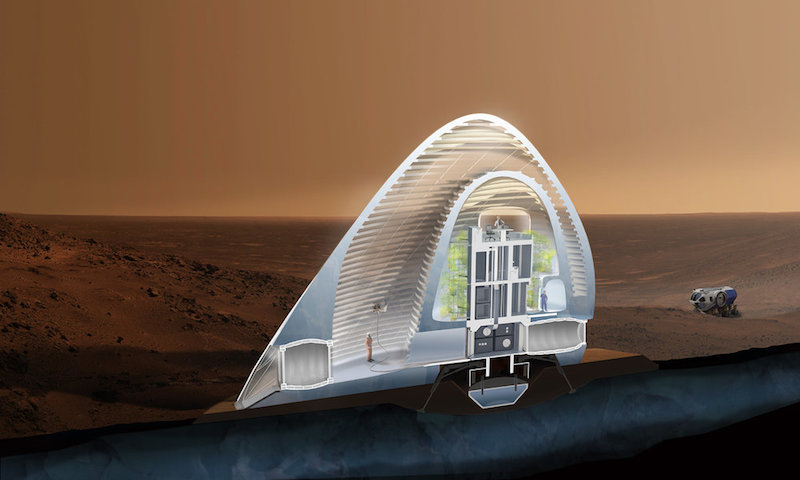

NASA’s Langley Research Center in Hampton, Va., recently revealed its design concept for the “Mars Ice Home,” which was developed with help from Space Exploration Architecture and the Clouds Architecture Office.

An inflatable inner-tube-like material would provide the actual living quarters for the astronauts while its exterior would be encased in a shell of 3D-printed ice. The ice would protect the structure, and those living within it, from cosmic rays, which are one of the biggest health concerns associated with humans living on Mars. While the ice structure would block the cosmic rays, it would still allow some light to pass through so it would more closely resemble living in a home than a cave or underground and allowing the astronauts to stay connected to natural diurnal cycles.

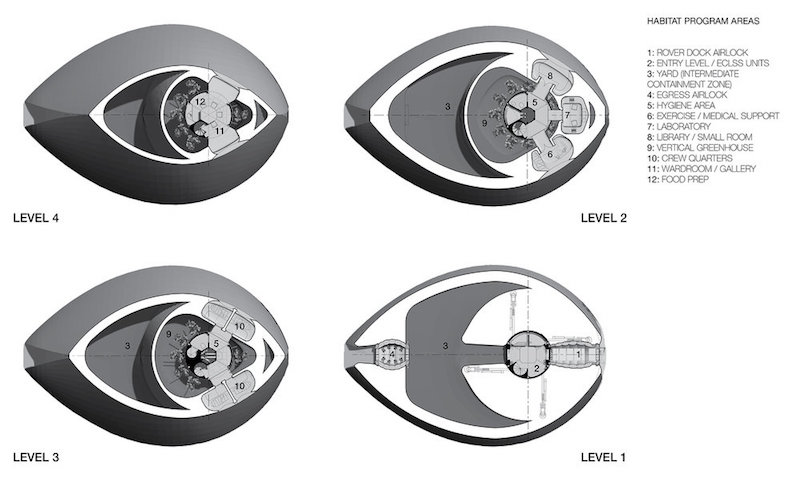

Cross section of the Mars Ice House. Courtesy of Space Exploration Architecture.

Cross section of the Mars Ice House. Courtesy of Space Exploration Architecture.

The ice shell would be five centimeters thick and is envisioned as a series of nested domes enclosed by a transparent ETFE (Ethylene tetrafluoroethylene) membrane. The outer shell creates a “front yard” that astronauts can occupy without the use of an EVA suit. The inner shell will provide a vertical hydroponic greenhouse that surrounds the inhabitants.

The Mars Ice House would be constructed without the need of a crew being present. The module would descend to the planet’s surface and land. Then the construction process would begin: the foundation is sintered, the ETFE membrane is inflated, the airlocks are deployed, the ice for the outer and inner shells is printed, and the plant-growing process beings. Only after all of this occurs does the crew arrive.

Since one of the biggest hurdles to building on Mars revolves around transporting any possible building materials to the planet, the lightness of the inflatable structure and the availability of ice on Mars make the Mars Ice Home a very intriguing possibility.

Courtesy of Space Exploration Architecture.

Courtesy of Space Exploration Architecture.

Another proposal for building on Mars uses the planets limited resources, as well, but instead of ice, a team of scientists from Northwestern University developed a form of “Martin concrete” that can be created using soil from the Red Planet, Dezeen reports.

The concrete is created by mixing the soil with molten sulfur and, according to the scientists, could be used to build entire villages on Mars. Most importantly, the concrete doesn’t require any water to make. The building material can endure low temperatures, is resistant to acid and salt, and can be melted down and recycled to build a different structure.

The idea of using the soil found on Mars to create a building material is not a new one. Foster + Partners created a concept for a 3D-printed habitat built by robots that uses regolith, loose soil, and rocks as the building materials, but according to Dezeen, this is the first time a report has detailed how this could actually be feasible.

After a series of trial and error experiments, the team, consisting of Lin Wan, Roman Wendner, and Gianluca Cusatis, determined an even mix of sulfur and aggregate would produce a material with a strength of 50 megapascals. When the difference of gravity on the surface of Mars is factored in, the material will be three times stronger, making it suitable for building on Mars.

The time it takes to travel to Mars makes the necessity of building a habitat for the astronauts on its surface unavoidable. While the development of Martian architecture may seem like nothing more than an exercise in creativity, it is actually an integral part of one day setting foot on Mars.

The "front yard" of the Mars Ice House. Courtesy of Space Exploration Architecture.

The "front yard" of the Mars Ice House. Courtesy of Space Exploration Architecture.

Foster + Partners' 3D-printed proposal. Courtesy of Foster + Partners.

Foster + Partners' 3D-printed proposal. Courtesy of Foster + Partners.

Related Stories

| Dec 14, 2011

Tyler Junior College and Sika Sarnafil team up to save energy

Tyler Junior College wanted a roofing system that wouldn’t need any attention for a long time.

| Dec 13, 2011

Lutron’s Commercial Experience Center awarded LEED Gold

LEED certification of the Lutron facility was based on a number of green design and construction features that positively impact the project itself and the broader community. These features include: optimization of energy performance through the use of lighting power, lighting controls and HVAC, plus the use of daylight.

| Dec 12, 2011

AIA Chicago announces Skidmore, Owings & Merrill as 2011 Firm of the Year

SOM has been a leader in the research and development of specialized technologies, new processes and innovative ideas, many of which have had a palpable and lasting impact on the design profession and the physical environment.

| Dec 12, 2011

Mojo Stumer takes top honors at AIA Long Island Design Awards

Firm's TriBeCa Loft wins "Archi" for interior design.

| Dec 10, 2011

10 Great Solutions

The editors of Building Design+Construction present 10 “Great Solutions” that highlight innovative technology and products that can be used to address some of the many problems Building Teams face in their day-to-day work. Readers are encouraged to submit entries for Great Solutions; if we use yours, you’ll receive a $25 gift certificate. Look for more Great Solutions in 2012 at: www.bdcnetwork.com/greatsolutions/2012.

| Dec 10, 2011

Energy performance starts at the building envelope

Rainscreen system installed at the west building expansion of the University of Arizona’s Meinel Optical Sciences Center in Tucson, with its folded glass wall and copper-paneled, breathable cladding over precast concrete.

| Dec 10, 2011

Turning Balconies Outside In

Operable glass balcony glazing systems provide solution to increase usable space in residential and commercial structures.

| Dec 10, 2011

BIM tools to make your project easier to manage

Two innovations—program manager Gafcon’s SharePoint360 project management platform and a new BIM “wall creator” add-on developed by ClarkDietrich Building Systems for use with the Revit BIM platform and construction consultant—show how fabricators and owner’s reps are stepping in to fill the gaps between construction and design that can typically be exposed by working with a 3D model.

| Dec 7, 2011

NSF International qualifies first wallcoverings distributor to the New American National Standard for Sustainable Wallcoverings

TRI-KES demonstrates leadership in environmental stewardship as the first distributor to earn qualification.

| Dec 7, 2011

Autodesk agrees to acquire Horizontal Systems

Acquisition extends and accelerates cloud-based BIM solutions for collaboration, data, and lifecycle management.