At some point in the past year or so, you have probably heard the term “hyperloop” thrown around as the future of transportation. Elon Musk first unveiled the concept of a hyperloop in 2013, Dezeen reports. Since that time, however, he open-sourced the technology and is no longer directly involved with the development.

This gave other companies, such as Hyperloop One, the opportunity to take the hyperloop from concept to reality. The company describes its hyperloop system on its website by writing, “The system uses electric propulsion to accelerate a passenger or cargo vehicle through a tube in a low pressure environment. The autonomous vehicle levitates slightly above the track and glides at faster-than-airline speeds over long distances. We eliminate direct emissions, noise, delay, weather concerns and pilot error.”

The idea of a hyperloop may seem more science fiction than fact, but it is actually grounded in reality. Hyperloop One, with the help of Danish design firm BIG, has big plans of connecting Dubai and Abu Dhabi via a hyperloop, bringing travel time between the two cities down to just 12 minutes. Riyadh would be reached in 48 minutes, Doha in 23 minutes, and Muscat in 27 minutes. The hyperloop pods that hold the passengers and their cargo will be able to reach speeds of up to 1,100 kilometers per hour.

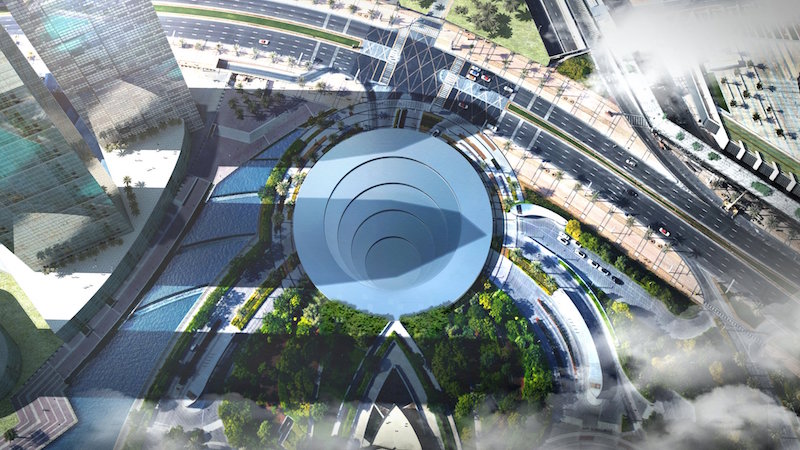

BIG’s designs show the Dubai station, dubbed the “portal” due to its sunken and circular styling, situated at the foot of the Burj Khalifa, according to the most recent information from Dezeen.

Each pod has room for six people and is loaded onto a transporter vessel attached to a chassis, although, the pods will differ with plans for specific offerings for business, lounge, and single. The pods themselves are autonomous and can leave the transporter, travel onto regular roads, and pick up passengers at any point, according to BIG.

The portal eliminates waiting halls through the use of frequent arrival and departure times.

Along with BIG, engineering firms AECOM and Arup are also working with Hyperloop One in an effort to become the first team to build a hyperloop system. Hyperloop One tested its propulsion technology earlier this year near Las Vegas and achieved speeds of 187 kilometers per hour in 1.1 seconds.

Currently, Hyperloop One’s top competitor is Hyperloop Transportation Technologies, which has a test track under construction in California and plans to connect Budapest, Vienna, and Bratislava with a hyperloop in the near future.

You can watch a video from BIG detailing how Hyperloop One’s system would work and be laid out below.

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Related Stories

Smart Buildings | Jul 25, 2024

A Swiss startup devises an intelligent photovoltaic façade that tracks and moves with the sun

Zurich Soft Robotics says Solskin can reduce building energy consumption by up to 80% while producing up to 40% more electricity than comparable façade systems.

Codes and Standards | Jul 25, 2024

GSA and DOE select technologies to evaluate for commercial building decarbonization

The General Services Administration and the U.S. Department of Energy have selected 17 innovative building technologies to evaluate in real-world settings throughout GSA’s real estate portfolio.

Great Solutions | Jul 23, 2024

41 Great Solutions for architects, engineers, and contractors

AI ChatBots, ambient computing, floating MRIs, low-carbon cement, sunshine on demand, next-generation top-down construction. These and 35 other innovations make up our 2024 Great Solutions Report, which highlights fresh ideas and innovations from leading architecture, engineering, and construction firms.

Building Technology | Jun 18, 2024

Could ‘smart’ building facades heat and cool buildings?

A promising research project looks at the possibilities for thermoelectric systems to thermally condition buildings, writes Mahsa Farid Mohajer, Sustainable Building Analyst with Stantec.

Concrete Technology | Jun 17, 2024

MIT researchers are working on a way to use concrete as an electric battery

Researchers at MIT have developed a concrete mixture that can store electrical energy. The researchers say the mixture of water, cement, and carbon black could be used for building foundations and street paving.

Contractors | Jun 4, 2024

Contractors expect to spend more time on prefabrication, according to FMI study

Get ready for a surge in prefabrication activity by contractors. FMI, the consulting and investment banking firm, recently polled contractors about how much time they were spending, in craft labor hours, on prefabrication for construction projects. More than 250 contractors participated in the survey, and the average response to that question was 18%. More revealing, however, was the participants’ anticipation that craft hours dedicated to prefab would essentially double, to 34%, within the next five years.

MFPRO+ New Projects | May 29, 2024

Two San Francisco multifamily high rises install onsite water recycling systems

Two high-rise apartment buildings in San Francisco have installed onsite water recycling systems that will reuse a total of 3.9 million gallons of wastewater annually. The recycled water will be used for toilet flushing, cooling towers, and landscape irrigation to significantly reduce water usage in both buildings.

HVAC | May 28, 2024

Department of Energy unveils resources for deploying heat pumps in commercial buildings

To accelerate adoption of heat pump technology in commercial buildings, the U.S. Department of Energy is offering resources and guidance for stakeholders. DOE aims to help commercial building owners and operators reduce greenhouse gas emissions and operating costs by increasing the adoption of existing and emerging heat pump technologies.

Building Tech | May 21, 2024

In a world first, load-bearing concrete walls built with a 3D printer

A Germany-based construction engineering company says it has constructed the world’s first load-bearing concrete walls built with a 3D printer. Züblin built a new warehouse from a single 3D print for Strabag Baumaschinentechnik International in Stuttgart, Germany using a Putzmeister 3D printer.

Codes and Standards | Apr 30, 2024

Updated document details methods of testing fenestration for exterior walls

The Fenestration and Glazing Industry Alliance (FGIA) updated a document serving a recommended practice for determining test methodology for laboratory and field testing of exterior wall systems. The document pertains to products covered by an AAMA standard such as curtain walls, storefronts, window walls, and sloped glazing. AAMA 501-24, Methods of Test for Exterior Walls was last updated in 2015.