At some point in the past year or so, you have probably heard the term “hyperloop” thrown around as the future of transportation. Elon Musk first unveiled the concept of a hyperloop in 2013, Dezeen reports. Since that time, however, he open-sourced the technology and is no longer directly involved with the development.

This gave other companies, such as Hyperloop One, the opportunity to take the hyperloop from concept to reality. The company describes its hyperloop system on its website by writing, “The system uses electric propulsion to accelerate a passenger or cargo vehicle through a tube in a low pressure environment. The autonomous vehicle levitates slightly above the track and glides at faster-than-airline speeds over long distances. We eliminate direct emissions, noise, delay, weather concerns and pilot error.”

The idea of a hyperloop may seem more science fiction than fact, but it is actually grounded in reality. Hyperloop One, with the help of Danish design firm BIG, has big plans of connecting Dubai and Abu Dhabi via a hyperloop, bringing travel time between the two cities down to just 12 minutes. Riyadh would be reached in 48 minutes, Doha in 23 minutes, and Muscat in 27 minutes. The hyperloop pods that hold the passengers and their cargo will be able to reach speeds of up to 1,100 kilometers per hour.

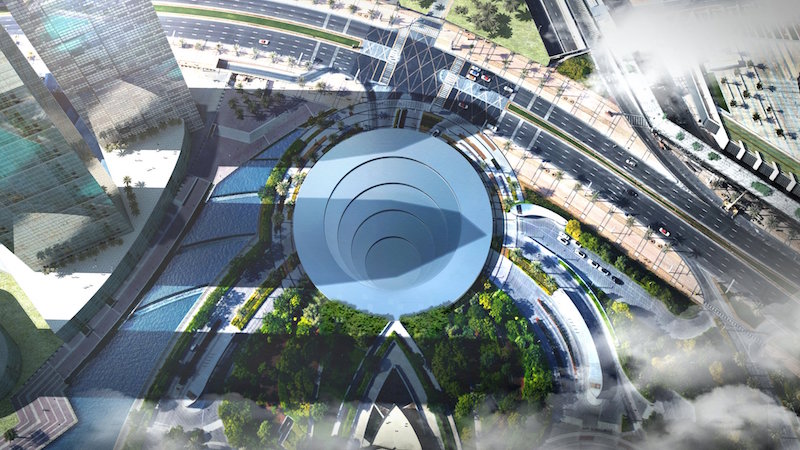

BIG’s designs show the Dubai station, dubbed the “portal” due to its sunken and circular styling, situated at the foot of the Burj Khalifa, according to the most recent information from Dezeen.

Each pod has room for six people and is loaded onto a transporter vessel attached to a chassis, although, the pods will differ with plans for specific offerings for business, lounge, and single. The pods themselves are autonomous and can leave the transporter, travel onto regular roads, and pick up passengers at any point, according to BIG.

The portal eliminates waiting halls through the use of frequent arrival and departure times.

Along with BIG, engineering firms AECOM and Arup are also working with Hyperloop One in an effort to become the first team to build a hyperloop system. Hyperloop One tested its propulsion technology earlier this year near Las Vegas and achieved speeds of 187 kilometers per hour in 1.1 seconds.

Currently, Hyperloop One’s top competitor is Hyperloop Transportation Technologies, which has a test track under construction in California and plans to connect Budapest, Vienna, and Bratislava with a hyperloop in the near future.

You can watch a video from BIG detailing how Hyperloop One’s system would work and be laid out below.

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Related Stories

Contractors | Apr 10, 2023

What makes prefabrication work? Factors every construction project should consider

There are many factors requiring careful consideration when determining whether a project is a good fit for prefabrication. JE Dunn’s Brian Burkett breaks down the most important considerations.

Smart Buildings | Apr 7, 2023

Carnegie Mellon University's research on advanced building sensors provokes heated controversy

A research project to test next-generation building sensors at Carnegie Mellon University provoked intense debate over the privacy implications of widespread deployment of the devices in a new 90,000-sf building. The light-switch-size devices, capable of measuring 12 types of data including motion and sound, were mounted in more than 300 locations throughout the building.

Cladding and Facade Systems | Apr 5, 2023

Façade innovation: University of Stuttgart tests a ‘saturated building skin’ for lessening heat islands

HydroSKIN is a façade made with textiles that stores rainwater and uses it later to cool hot building exteriors. The façade innovation consists of an external, multilayered 3D textile that acts as a water collector and evaporator.

Project + Process Innovation | Mar 22, 2023

Onsite prefabrication for healthcare construction: It's more than a process, it's a partnership

Prefabrication can help project teams navigate an uncertain market. GBBN's Mickey LeRoy, AIA, ACHA, LEED AP, explains the difference between onsite and offsite prefabrication methods for healthcare construction projects.

Building Tech | Mar 14, 2023

Reaping the benefits of offsite construction, with ICC's Ryan Colker

Ryan Colker, VP of Innovation at the International Code Council, discusses how municipal regulations and inspections are keeping up with the expansion of off-site manufacturing for commercial construction. Colker speaks with BD+C's John Caulfield.

Student Housing | Mar 13, 2023

University of Oklahoma, Missouri S&T add storm-safe spaces in student housing buildings for tornado protection

More universities are incorporating reinforced rooms in student housing designs to provide an extra layer of protection for students. Storm shelters have been included in recent KWK Architects-designed university projects in the Great Plains where there is a high incidence of tornadoes. Projects include Headington and Dunham Residential Colleges at the University of Oklahoma and the University Commons residential complex at Missouri S&T.

AEC Innovators | Mar 3, 2023

Meet BD+C's 2023 AEC Innovators

More than ever, AEC firms and their suppliers are wedding innovation with corporate responsibility. How they are addressing climate change usually gets the headlines. But as the following articles in our AEC Innovators package chronicle, companies are attempting to make an impact as well on the integrity of their supply chains, the reduction of construction waste, and answering calls for more affordable housing and homeless shelters. As often as not, these companies are partnering with municipalities and nonprofit interest groups to help guide their production.

Modular Building | Mar 3, 2023

Pallet Shelter is fighting homelessness, one person and modular pod at a time

Everett, Wash.-based Pallet Inc. helped the City of Burlington, Vt., turn a municipal parking lot into an emergency shelter community, complete with 30 modular “sleeping cabins” for the homeless.

Multifamily Housing | Mar 1, 2023

Multifamily construction startup Cassette takes a different approach to modular building

Prefabricated modular design and construction have made notable inroads into such sectors as industrial, residential, hospitality and, more recently, office and healthcare. But Dafna Kaplan thinks that what’s held back the modular building industry from even greater market penetration has been suppliers’ insistence that they do everything: design, manufacture, logistics, land prep, assembly, even onsite construction. Kaplan is CEO and Founder of Cassette, a Los Angeles-based modular building startup.

Sustainability | Feb 8, 2023

A wind energy system—without the blades—can be placed on commercial building rooftops

Aeromine Technologies’ bladeless system captures and amplifies a building’s airflow like airfoils on a race car.