At some point in the past year or so, you have probably heard the term “hyperloop” thrown around as the future of transportation. Elon Musk first unveiled the concept of a hyperloop in 2013, Dezeen reports. Since that time, however, he open-sourced the technology and is no longer directly involved with the development.

This gave other companies, such as Hyperloop One, the opportunity to take the hyperloop from concept to reality. The company describes its hyperloop system on its website by writing, “The system uses electric propulsion to accelerate a passenger or cargo vehicle through a tube in a low pressure environment. The autonomous vehicle levitates slightly above the track and glides at faster-than-airline speeds over long distances. We eliminate direct emissions, noise, delay, weather concerns and pilot error.”

The idea of a hyperloop may seem more science fiction than fact, but it is actually grounded in reality. Hyperloop One, with the help of Danish design firm BIG, has big plans of connecting Dubai and Abu Dhabi via a hyperloop, bringing travel time between the two cities down to just 12 minutes. Riyadh would be reached in 48 minutes, Doha in 23 minutes, and Muscat in 27 minutes. The hyperloop pods that hold the passengers and their cargo will be able to reach speeds of up to 1,100 kilometers per hour.

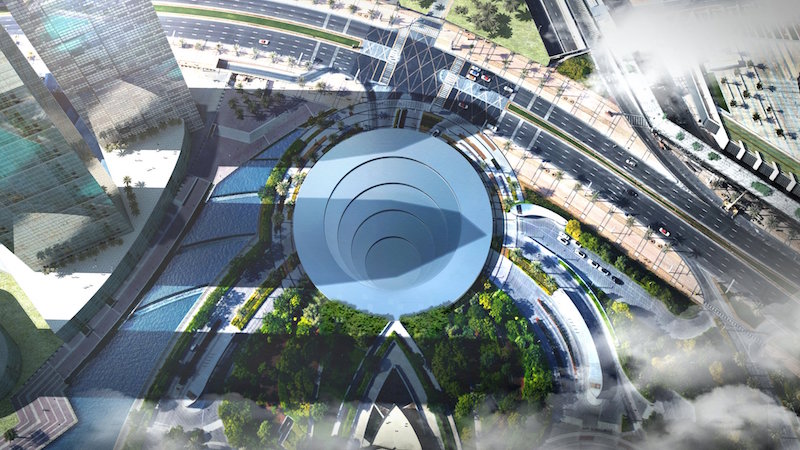

BIG’s designs show the Dubai station, dubbed the “portal” due to its sunken and circular styling, situated at the foot of the Burj Khalifa, according to the most recent information from Dezeen.

Each pod has room for six people and is loaded onto a transporter vessel attached to a chassis, although, the pods will differ with plans for specific offerings for business, lounge, and single. The pods themselves are autonomous and can leave the transporter, travel onto regular roads, and pick up passengers at any point, according to BIG.

The portal eliminates waiting halls through the use of frequent arrival and departure times.

Along with BIG, engineering firms AECOM and Arup are also working with Hyperloop One in an effort to become the first team to build a hyperloop system. Hyperloop One tested its propulsion technology earlier this year near Las Vegas and achieved speeds of 187 kilometers per hour in 1.1 seconds.

Currently, Hyperloop One’s top competitor is Hyperloop Transportation Technologies, which has a test track under construction in California and plans to connect Budapest, Vienna, and Bratislava with a hyperloop in the near future.

You can watch a video from BIG detailing how Hyperloop One’s system would work and be laid out below.

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Related Stories

Engineers | Jun 5, 2023

How to properly assess structural wind damage

Properly assessing wind damage can identify vulnerabilities in a building's design or construction, which could lead to future damage or loss, writes Matt Wagner, SE, Principal and Managing Director with Walter P Moore.

Cladding and Facade Systems | Jun 5, 2023

27 important questions about façade leakage

Walter P Moore’s Darek Brandt discusses the key questions building owners and property managers should be asking to determine the health of their building's façade.

Office Buildings | May 15, 2023

Sixteen-story office tower will use 40% less energy than an average NYC office building

This month marks the completion of a new 16-story office tower that is being promoted as New York City’s most sustainable office structure. That boast is backed by an innovative HVAC system that features geothermal wells, dedicated outdoor air system (DOAS) units, radiant heating and cooling, and a sophisticated control system to ensure that the elements work optimally together.

AEC Tech Innovation | May 12, 2023

Meet Diverge, Hensel Phelps' new ConTech investment company

Thai Nguyen, Director of Innovation with Hensel Phelps, discusses the construction giant's new startup investment platform, Diverge.

University Buildings | May 5, 2023

New health sciences center at St. John’s University will feature geothermal heating, cooling

The recently topped off St. Vincent Health Sciences Center at St. John’s University in New York City will feature impressive green features including geothermal heating and cooling along with an array of rooftop solar panels. The geothermal field consists of 66 wells drilled 499 feet below ground which will help to heat and cool the 70,000 sf structure.

Mass Timber | May 3, 2023

Gensler-designed mid-rise will be Houston’s first mass timber commercial office building

A Houston project plans to achieve two firsts: the city’s first mass timber commercial office project, and the state of Texas’s first commercial office building targeting net zero energy operational carbon upon completion next year. Framework @ Block 10 is owned and managed by Hicks Ventures, a Houston-based development company.

AEC Tech | May 1, 2023

Utilizing computer vision, AI technology for visual jobsite tasks

Burns & McDonnell breaks down three ways computer vision can effectively assist workers on the job site, from project progress to safety measures.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.