This fall, the world’s tallest modular hotel—a 26-story, 360-foot-tall building that will be branded AC Hotel New York NoMad when it opens late next year—will start stacking prefabricated and prefurnished guestrooms for assembly in New York City.

This is one of 50 projects that Marriott International, since launching its pilot modular initiative in 2015, has incorporated prefab guestrooms or bathrooms.

In May, the hotelier developed specific modular concepts for its Fairfield Inn, Courtyard, SpringHill Suites, TownePlace, and Four Points by Sheraton brands. It deploys modular construction for its AC Hotels brand, and later this year will start stacking its first modular-built Moxy hotel in the U.S., in Oakland, Calif.

Jennifer Abuzeid, Senior Director–Global Design Strategies, says that Marriott began exploring modular construction in response to its post-recession pipeline expanding. (That pipeline currently exceeds 4,000 hotels for all of its brands.) Couple that with a dicey labor market, which put a major crimp in scheduling: a 120- to 150-room Courtyard hotel was taking 21 months to complete, compared to 12 months prerecession, says Abuzeid.

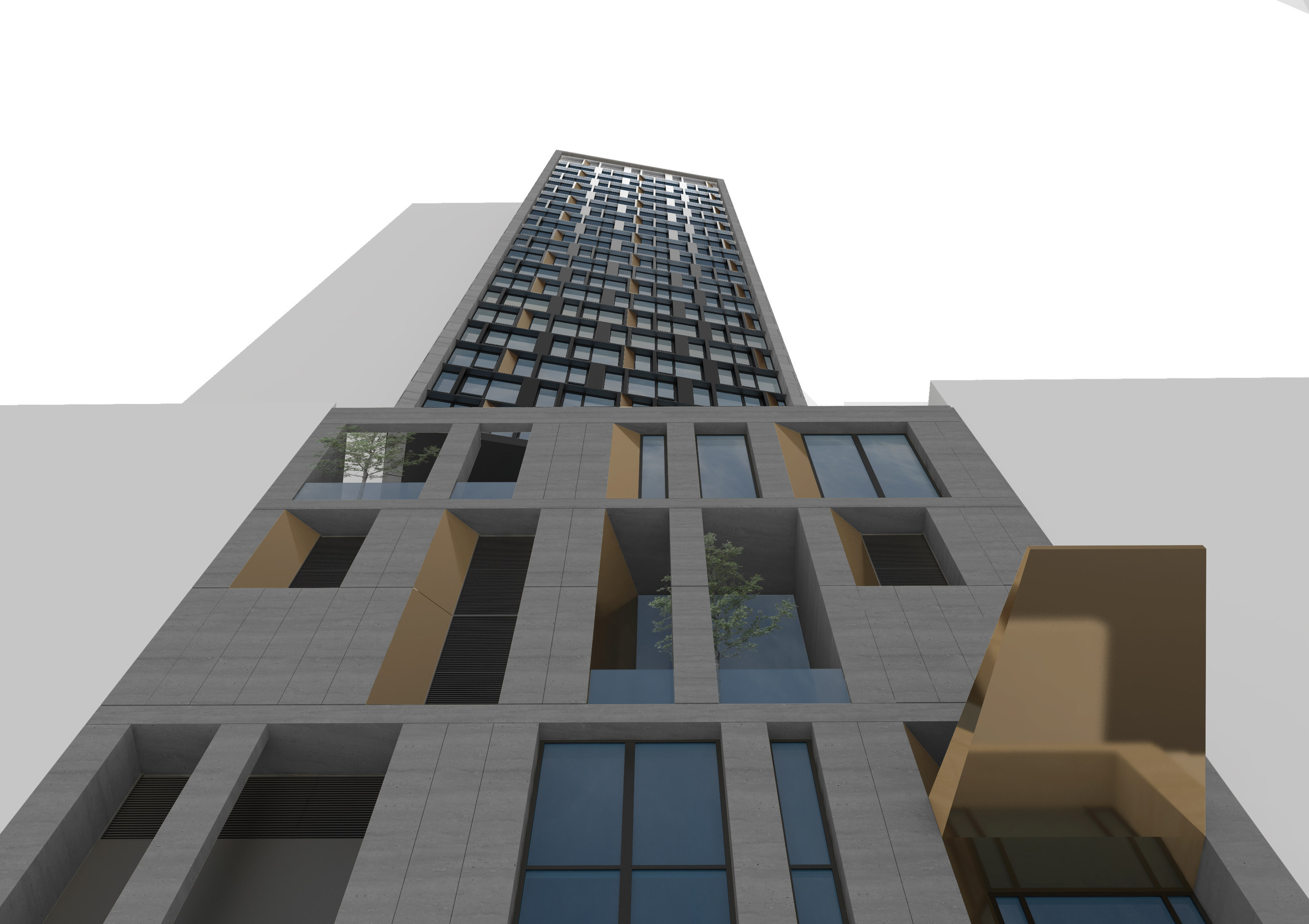

At 26 stories and 360 feet, Marriott International's AC Hotel New York NoMad will be the world’s tallest modular hotel when it opens next year. Besides finished, painted walls, each module will contain a fully outfitted guest room, with beds, sheets, pillows, flooring, even toiletries, according to architect Danny Forster & Architecture. Associate architect: Epstein. Photo courtesy Marriott Intl. and Danny Forster & Architecture

At 26 stories and 360 feet, Marriott International's AC Hotel New York NoMad will be the world’s tallest modular hotel when it opens next year. Besides finished, painted walls, each module will contain a fully outfitted guest room, with beds, sheets, pillows, flooring, even toiletries, according to architect Danny Forster & Architecture. Associate architect: Epstein. Photo courtesy Marriott Intl. and Danny Forster & Architecture

Abuzeid admits that Marriott’s embrace of modular construction has been a learning curve. Finding enough module manufacturers to meet its needs continues to be a battle. Skystone Group is the General Contractor and Modular Manufacturer on this New York AC Hotel project. It manufactures the modules using a Europe-based supply chain: DMD Modular, STP Elbud, and Aluprof are the main subcontractors contributing to the modular scope, according to Greg Thompson, Chief Financial Officer for Skystone Group.*

But the “great benefits” of modular, she says, include consistent product quality, eliminating change orders, and reducing punch lists and jobsite waste.

Marriott has an in-house design team that sets the prototype parameters for its brands. Its franchisees hire the building teams and module suppliers to construct the hotels. This year, Marriott began offering incentives to developers that leverage prefabrication for guestroom construction.

SEE ALSO: Mace Group built working factories on top of under-construction skyscrapers

Abuzeid estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.”

Abuzeid estimates that 40% of Marriott’s Select brands in North America, which account for more than two-fifths of its backlog, has the potential for modular construction.

“We consider modular design and construction very important to our expansion strategy in North America, where it’s currently not as commonly leveraged as in other parts of the world,” says Eric Jacobs, Marriott International’s Chief Development Officer for Marriott Select Service and Extended Stay Brands in North America.

*Information about Skystone Group's role Marriott's AC Hotel project was added after this story was originally posted.

Marriott's Jennifer Abuzeid, Senior Director–Global Design Strategies, estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.” Photo: Marriott

Marriott's Jennifer Abuzeid, Senior Director–Global Design Strategies, estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.” Photo: Marriott

Related Stories

Contractors | May 26, 2023

Enhanced use of data is crucial for improving construction job site safety

Executives with major construction companies say new digital tools are allowing them to use data more effectively to reduce serious safety incidents and improve job site safety.

AEC Tech Innovation | May 12, 2023

Meet Diverge, Hensel Phelps' new ConTech investment company

Thai Nguyen, Director of Innovation with Hensel Phelps, discusses the construction giant's new startup investment platform, Diverge.

Sustainability | May 1, 2023

Increased focus on sustainability is good for business and attracting employees

A recent study, 2023 State of Design & Make by software developer Autodesk, contains some interesting takeaways for the design and construction industry. Respondents to a survey of industry leaders from the architecture, engineering, construction, product design, manufacturing, and entertainment spheres strongly support the idea that improving their organization’s sustainability practices is good for business.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

AEC Tech Innovation | Apr 27, 2023

Does your firm use ChatGPT?

Is your firm having success utilizing ChatGPT (or other AI chat tools) on your building projects or as part of your business operations? If so, we want to hear from you.

Design Innovation Report | Apr 19, 2023

Reinforced concrete walls and fins stiffen and shade the National Bank of Kuwait skyscraper

When the National Bank of Kuwait first conceived its new headquarters more than a decade ago, it wanted to make a statement about passive design with a soaring tower that could withstand the extreme heat of Kuwait City, the country’s desert capital.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

Design Innovation Report | Apr 19, 2023

Meet The Hithe: A demountable building for transient startups

The Hithe, near London, is designed to be demountable and reusable. The 2,153-sf building provides 12 units of business incubator workspace for startups.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.

Smart Buildings | Apr 7, 2023

Carnegie Mellon University's research on advanced building sensors provokes heated controversy

A research project to test next-generation building sensors at Carnegie Mellon University provoked intense debate over the privacy implications of widespread deployment of the devices in a new 90,000-sf building. The light-switch-size devices, capable of measuring 12 types of data including motion and sound, were mounted in more than 300 locations throughout the building.