This fall, the world’s tallest modular hotel—a 26-story, 360-foot-tall building that will be branded AC Hotel New York NoMad when it opens late next year—will start stacking prefabricated and prefurnished guestrooms for assembly in New York City.

This is one of 50 projects that Marriott International, since launching its pilot modular initiative in 2015, has incorporated prefab guestrooms or bathrooms.

In May, the hotelier developed specific modular concepts for its Fairfield Inn, Courtyard, SpringHill Suites, TownePlace, and Four Points by Sheraton brands. It deploys modular construction for its AC Hotels brand, and later this year will start stacking its first modular-built Moxy hotel in the U.S., in Oakland, Calif.

Jennifer Abuzeid, Senior Director–Global Design Strategies, says that Marriott began exploring modular construction in response to its post-recession pipeline expanding. (That pipeline currently exceeds 4,000 hotels for all of its brands.) Couple that with a dicey labor market, which put a major crimp in scheduling: a 120- to 150-room Courtyard hotel was taking 21 months to complete, compared to 12 months prerecession, says Abuzeid.

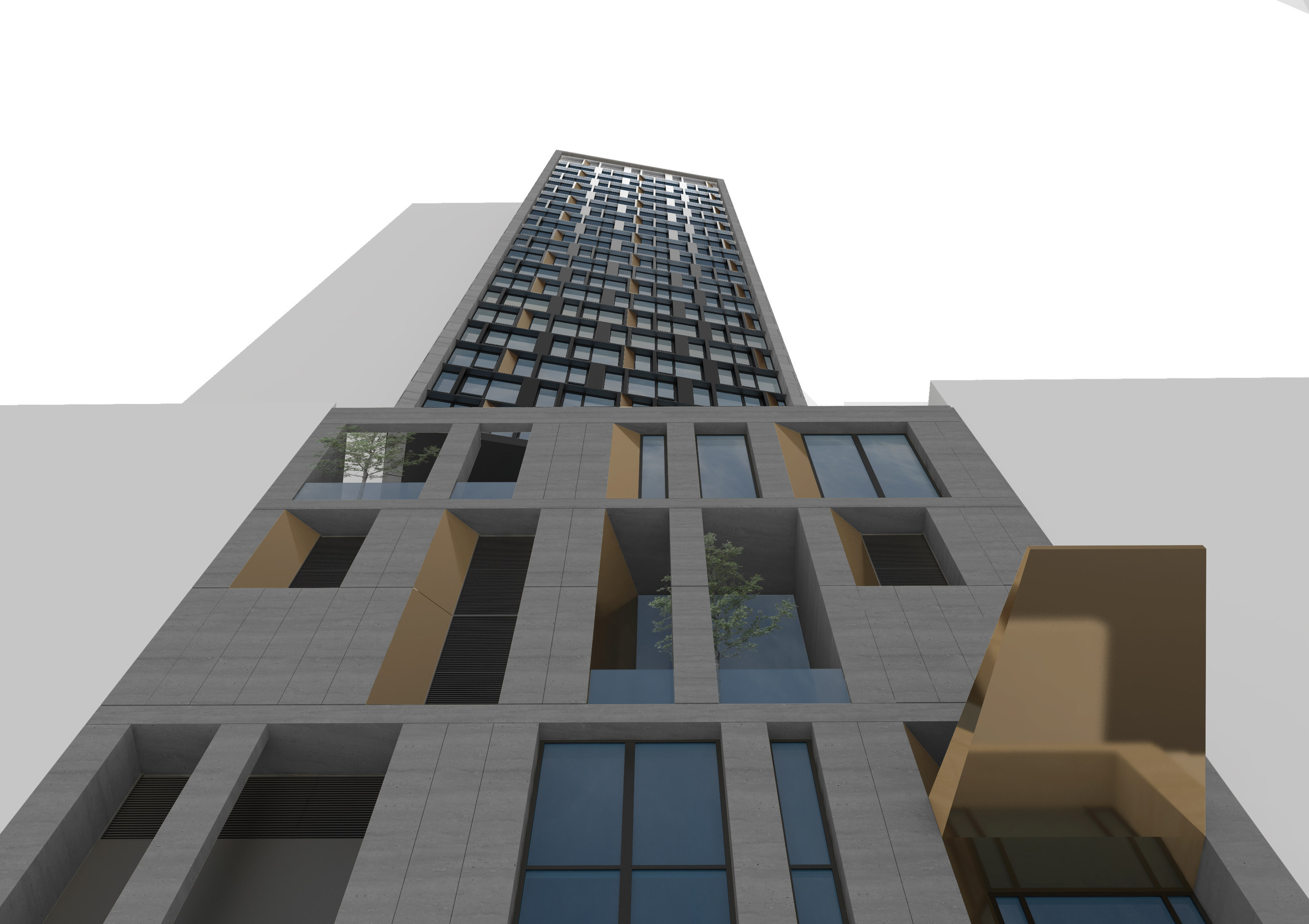

At 26 stories and 360 feet, Marriott International's AC Hotel New York NoMad will be the world’s tallest modular hotel when it opens next year. Besides finished, painted walls, each module will contain a fully outfitted guest room, with beds, sheets, pillows, flooring, even toiletries, according to architect Danny Forster & Architecture. Associate architect: Epstein. Photo courtesy Marriott Intl. and Danny Forster & Architecture

At 26 stories and 360 feet, Marriott International's AC Hotel New York NoMad will be the world’s tallest modular hotel when it opens next year. Besides finished, painted walls, each module will contain a fully outfitted guest room, with beds, sheets, pillows, flooring, even toiletries, according to architect Danny Forster & Architecture. Associate architect: Epstein. Photo courtesy Marriott Intl. and Danny Forster & Architecture

Abuzeid admits that Marriott’s embrace of modular construction has been a learning curve. Finding enough module manufacturers to meet its needs continues to be a battle. Skystone Group is the General Contractor and Modular Manufacturer on this New York AC Hotel project. It manufactures the modules using a Europe-based supply chain: DMD Modular, STP Elbud, and Aluprof are the main subcontractors contributing to the modular scope, according to Greg Thompson, Chief Financial Officer for Skystone Group.*

But the “great benefits” of modular, she says, include consistent product quality, eliminating change orders, and reducing punch lists and jobsite waste.

Marriott has an in-house design team that sets the prototype parameters for its brands. Its franchisees hire the building teams and module suppliers to construct the hotels. This year, Marriott began offering incentives to developers that leverage prefabrication for guestroom construction.

SEE ALSO: Mace Group built working factories on top of under-construction skyscrapers

Abuzeid estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.”

Abuzeid estimates that 40% of Marriott’s Select brands in North America, which account for more than two-fifths of its backlog, has the potential for modular construction.

“We consider modular design and construction very important to our expansion strategy in North America, where it’s currently not as commonly leveraged as in other parts of the world,” says Eric Jacobs, Marriott International’s Chief Development Officer for Marriott Select Service and Extended Stay Brands in North America.

*Information about Skystone Group's role Marriott's AC Hotel project was added after this story was originally posted.

Marriott's Jennifer Abuzeid, Senior Director–Global Design Strategies, estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.” Photo: Marriott

Marriott's Jennifer Abuzeid, Senior Director–Global Design Strategies, estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.” Photo: Marriott

Related Stories

Architects | Apr 6, 2023

New tool from Perkins&Will will make public health data more accessible to designers and architects

Called PRECEDE, the dashboard is an open-source tool developed by Perkins&Will that draws on federal data to identify and assess community health priorities within the U.S. by location. The firm was recently awarded a $30,000 ASID Foundation Grant to enhance the tool.

Cladding and Facade Systems | Apr 5, 2023

Façade innovation: University of Stuttgart tests a ‘saturated building skin’ for lessening heat islands

HydroSKIN is a façade made with textiles that stores rainwater and uses it later to cool hot building exteriors. The façade innovation consists of an external, multilayered 3D textile that acts as a water collector and evaporator.

Women in Design+Construction | Apr 5, 2023

Carole Wedge, former Shepley Bulfinch President and CEO, retires after 37 years

Wedge’s 37-year career at Shepley Bulfinch evolved a historic firm into a national design practice.

AEC Innovators | Mar 27, 2023

Leading architecture, engineering firm HED appoints new co-CEOs

As children of immigrant families, Van Herle and Suarez will bring a diverse perspective into a historically underrepresented industry and advance the firm’s mission of creating a positive impact for clients, communities, and the world.

Transportation & Parking Facilities | Mar 23, 2023

Amsterdam debuts underwater bicycle parking facility that can accommodate over 4,000 bikes

In February, Amsterdam saw the opening of a new underwater bicycle parking facility. Located in the heart of the city—next to Amsterdam Central Station and under the river IJ (Amsterdam’s waterfront)—the facility, dubbed IJboulevard, has parking spots for over 4,000 bicycles, freeing up space on the street.

Building Tech | Mar 14, 2023

Reaping the benefits of offsite construction, with ICC's Ryan Colker

Ryan Colker, VP of Innovation at the International Code Council, discusses how municipal regulations and inspections are keeping up with the expansion of off-site manufacturing for commercial construction. Colker speaks with BD+C's John Caulfield.

AEC Innovators | Mar 3, 2023

Meet BD+C's 2023 AEC Innovators

More than ever, AEC firms and their suppliers are wedding innovation with corporate responsibility. How they are addressing climate change usually gets the headlines. But as the following articles in our AEC Innovators package chronicle, companies are attempting to make an impact as well on the integrity of their supply chains, the reduction of construction waste, and answering calls for more affordable housing and homeless shelters. As often as not, these companies are partnering with municipalities and nonprofit interest groups to help guide their production.

Modular Building | Mar 3, 2023

Pallet Shelter is fighting homelessness, one person and modular pod at a time

Everett, Wash.-based Pallet Inc. helped the City of Burlington, Vt., turn a municipal parking lot into an emergency shelter community, complete with 30 modular “sleeping cabins” for the homeless.

AEC Innovators | Mar 2, 2023

Turner Construction extends its ESG commitment to thwarting forced labor in its supply chain

Turner Construction joins a growing AEC industry movement, inspired by the Design for Freedom initiative, to eliminate forced labor and child labor from the production and distribution of building products.

Multifamily Housing | Mar 1, 2023

Multifamily construction startup Cassette takes a different approach to modular building

Prefabricated modular design and construction have made notable inroads into such sectors as industrial, residential, hospitality and, more recently, office and healthcare. But Dafna Kaplan thinks that what’s held back the modular building industry from even greater market penetration has been suppliers’ insistence that they do everything: design, manufacture, logistics, land prep, assembly, even onsite construction. Kaplan is CEO and Founder of Cassette, a Los Angeles-based modular building startup.