When the general contractor learned that this newly constructed building’s concrete substrate had an average of one-inch deflection, the flooring contractor recommended a cementitious self-leveling underlayment to correct and flatten the floor. The GC anticipated that solving the problem would negatively affect the project schedule - they needed a fast and reliable solution.

Traditional installation methods would be time-consuming, costly and introduce unacceptable levels of respirable silica dust to the jobsite and to worker safety. The flooring contractor, Allegheny Contract, challenged using old, traditional SLU installation methods and recommended using the LATICRETE SUPERCAP system.

Allegheny Contract offered to conduct a monitored side-by-side comparison test using two different premium SLU products.

The General Contractor agreed and selected 2 identical 11,000 SF floor plates:

- Floor 4: Was installed with 50lb small bags of self-leveling underlayment loaded into the building on pallets and delivered through a traditional barrel mixing system.

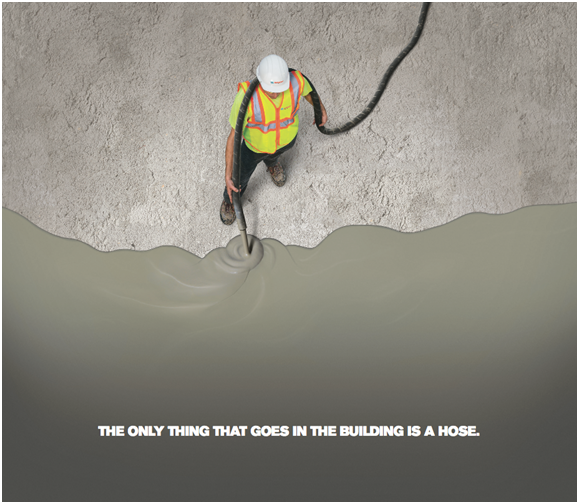

- Floor 5: Was installed with the LATICRETE SUPERCAP System, using 2,300lb supersacks of SC500 material mixed outside the building in a mobile blending unit and pumped through a hose into the building.

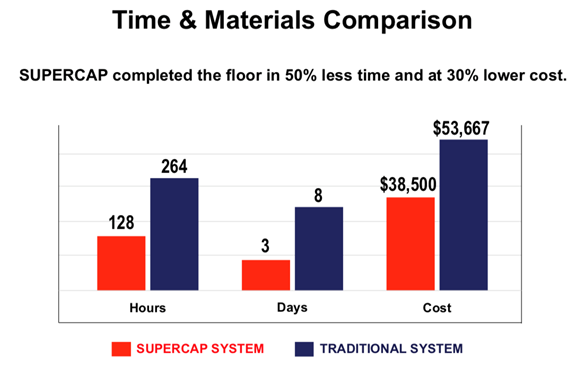

The Results:

The LATICRETE SUPERCAP System had the speed and volume, the mobile blending unit can pump up to 60 stories high, up to 50,000 SF in one day, at a rate of 30,000 lbs. per hour (equivalent to 600 small bags an hour). The only thing that goes into the building is a hose, no silica dust inside or outside the building. The projects LVT and wood floor flatness specs were easily met and the project stayed on schedule. The goal of providing a fast and cost-effective solution was achieved.

For more information, contact LATICRETE SUPERCAP at (866) 704-2247 or email us at info@laticretesupercap.com, or visit www.laticretesupercap.com

To view a project video of another LATICRETE SUPERCAP System Solution, visit: https://laticretesupercap.com/en/features-support/project-spotlights/colorado-mills-mall

Related Stories

Products and Materials | Jul 31, 2023

Top building products for July 2023

BD+C Editors break down 15 of the top building products this month, from cleanroom doors to window storm protection systems.

Building Materials | Jun 14, 2023

Construction input prices fall 0.6% in May 2023

Construction input prices fell 0.6% in May compared to the previous month, according to an Associated Builders and Contractors analysis of the U.S. Bureau of Labor Statistics’ Producer Price Index data released today. Nonresidential construction input prices declined 0.5% for the month.

75 Top Building Products | Nov 30, 2022

75 top building products for 2022

Each year, the Building Design+Construction editorial team evaluates the vast universe of new and updated products, materials, and systems for the U.S. building design and construction market. The best-of-the-best products make up our annual 75 Top Products report.

Multifamily Housing | Sep 13, 2022

Take the Multifamily Kitchen + Bath survey – Maybe win one of 10 $50 gift cards

Preliminary results of 2022 Multifamily Design+Construction exclusive Kitchen + Bath survey.

Building Materials | Aug 3, 2022

Shawmut CEO Les Hiscoe on coping with a shaky supply chain in construction

BD+C's John Caulfield interviews Les Hiscoe, CEO of Shawmut Design and Construction, about how his firm keeps projects on schedule and budget in the face of shortages, delays, and price volatility.

Codes and Standards | Jun 2, 2022

New design guide for hybrid steel-mass timber frames released

The American Institute of Steel Construction (AISC) has released the first-ever set of U.S. recommendations for hybrid steel frames with mass timber floors, according to a news release.

Products and Materials | Feb 24, 2022

MAXXON® Corporation announces strategic affiliation with S3 Surface Solutions

Maxxon® Corporation, creator of Gyp-Crete® and a leader in the underlayment industry for 50 years, has aligned with S3 Surface Solutions, an innovative manufacturer of products that address problematic concrete slabs, to bring innovative, technology-driven subfloor preparation solutions to the flooring industry.

75 Top Building Products | Dec 16, 2019

Top Flooring Products for 2019

Tarkett’s aviation-inspired flooring collection and J+J Flooring’s textile composite flooring are among the four new commercial flooring products to make Building Design+Construction’s 2019 101 Top Products report.

Flooring | Jun 21, 2018

Product roundup: Floor and wall tile collection

Project evolution from Ceramiche Caesar, Eminent Wood Maximum from Fiandre, and Voyage from Landmark are just three of the 12 products highlighted in BD+C's June Product Roundup.