When the general contractor learned that this newly constructed building’s concrete substrate had an average of one-inch deflection, the flooring contractor recommended a cementitious self-leveling underlayment to correct and flatten the floor. The GC anticipated that solving the problem would negatively affect the project schedule - they needed a fast and reliable solution.

Traditional installation methods would be time-consuming, costly and introduce unacceptable levels of respirable silica dust to the jobsite and to worker safety. The flooring contractor, Allegheny Contract, challenged using old, traditional SLU installation methods and recommended using the LATICRETE SUPERCAP system.

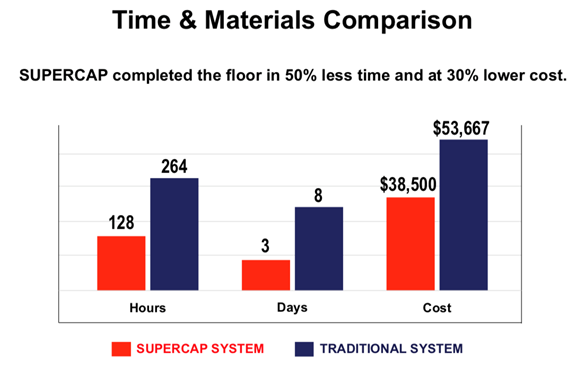

Allegheny Contract offered to conduct a monitored side-by-side comparison test using two different premium SLU products.

The General Contractor agreed and selected 2 identical 11,000 SF floor plates:

- Floor 4: Was installed with 50lb small bags of self-leveling underlayment loaded into the building on pallets and delivered through a traditional barrel mixing system.

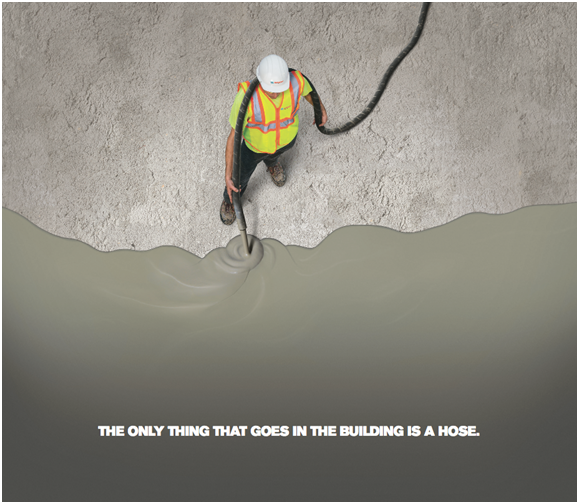

- Floor 5: Was installed with the LATICRETE SUPERCAP System, using 2,300lb supersacks of SC500 material mixed outside the building in a mobile blending unit and pumped through a hose into the building.

The Results:

The LATICRETE SUPERCAP System had the speed and volume, the mobile blending unit can pump up to 60 stories high, up to 50,000 SF in one day, at a rate of 30,000 lbs. per hour (equivalent to 600 small bags an hour). The only thing that goes into the building is a hose, no silica dust inside or outside the building. The projects LVT and wood floor flatness specs were easily met and the project stayed on schedule. The goal of providing a fast and cost-effective solution was achieved.

For more information, contact LATICRETE SUPERCAP at (866) 704-2247 or email us at info@laticretesupercap.com, or visit www.laticretesupercap.com

To view a project video of another LATICRETE SUPERCAP System Solution, visit: https://laticretesupercap.com/en/features-support/project-spotlights/colorado-mills-mall

Related Stories

75 Top Building Products | Mar 22, 2018

101 Top Products: Flooring 2018

Among the best flooring products included in BD+C's Top 101 Products report are Bostik's 'Climb' Low-VOC Adhesive and Schulter Systems Ditra Heat Duo Membrane.

Flooring | Nov 6, 2017

Rubber flooring ready for traffic at Calgary airport

More than 400,000 sf of norament grano and noraplan sentica cover portions of the international terminal and Connections Corridor.

Green | Sep 27, 2017

Wellness gains ground with real estate and property management professionals

Structure Tone survey finds LEED is still a selling point, but interest in resilience practices could be waning.

Sponsored | Flooring | Aug 24, 2017

Radiant heating provides poolside comfort

Radiant heats the objects in a room, making the environment more comfortable without the energy-intensive process of heating air.

Sponsored | Flooring | Aug 22, 2017

INSTALL revives acute care facility with forward-thinking installation

A complex installation and a phased timeline were executed flawlessly in a fully functional acute care facility thanks to a highly skilled, INSTALL-trained team.

Fire-Rated Products | Aug 15, 2017

Walking on glass: Clear floor system offers largest two-hour fire- resistive panels

The system uses the largest tested and listed individual glass panels for two-hour fire-resistive glass floor applications.

Products and Materials | Jul 21, 2017

Acrylic-infused wood flooring brings durability for commercial spaces

The product incorporates an acrylic-infused top layer.

Flooring | Jul 12, 2017

Membrane dials down the sound, while it cranks up the heat

A new membrane from Schluter Systems, Ditra Heat Duo, reduces sound transmission while also warming the floor and supporting the covering to ensure lasting installation.

Sponsored | Flooring | Jun 5, 2017

INSTALL sets stage for inspiration with expert installation

The challenge of a large space, mixed materials and intricate design were met by a highly skilled, INSTALL-trained team.

Sponsored | Flooring | Dec 7, 2016

Reading Hospital expansion project saves two months in construction schedule thanks to nora nTx

Construction delays are common with projects as large as the $354 million Reading Hospital expansion. Maybe that’s why construction manager Jeff Hutwelker, project executive with LF Driscoll Co., LLC, was so pleased with his nora® experience. By Hutwelker’s estimates, nora nTx saved approximately two months in his construction schedule.