When the general contractor learned that this newly constructed building’s concrete substrate had an average of one-inch deflection, the flooring contractor recommended a cementitious self-leveling underlayment to correct and flatten the floor. The GC anticipated that solving the problem would negatively affect the project schedule - they needed a fast and reliable solution.

Traditional installation methods would be time-consuming, costly and introduce unacceptable levels of respirable silica dust to the jobsite and to worker safety. The flooring contractor, Allegheny Contract, challenged using old, traditional SLU installation methods and recommended using the LATICRETE SUPERCAP system.

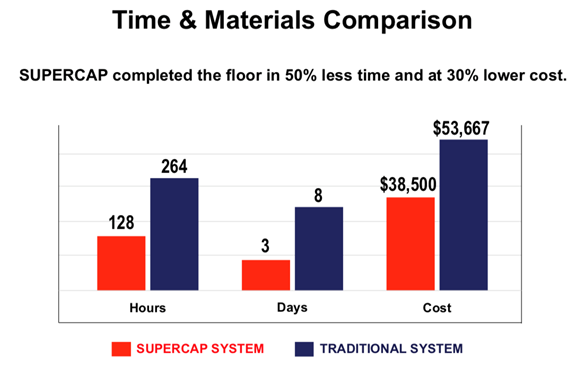

Allegheny Contract offered to conduct a monitored side-by-side comparison test using two different premium SLU products.

The General Contractor agreed and selected 2 identical 11,000 SF floor plates:

- Floor 4: Was installed with 50lb small bags of self-leveling underlayment loaded into the building on pallets and delivered through a traditional barrel mixing system.

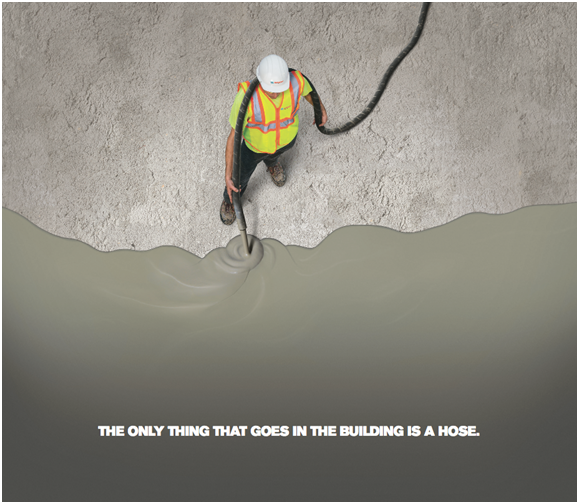

- Floor 5: Was installed with the LATICRETE SUPERCAP System, using 2,300lb supersacks of SC500 material mixed outside the building in a mobile blending unit and pumped through a hose into the building.

The Results:

The LATICRETE SUPERCAP System had the speed and volume, the mobile blending unit can pump up to 60 stories high, up to 50,000 SF in one day, at a rate of 30,000 lbs. per hour (equivalent to 600 small bags an hour). The only thing that goes into the building is a hose, no silica dust inside or outside the building. The projects LVT and wood floor flatness specs were easily met and the project stayed on schedule. The goal of providing a fast and cost-effective solution was achieved.

For more information, contact LATICRETE SUPERCAP at (866) 704-2247 or email us at info@laticretesupercap.com, or visit www.laticretesupercap.com

To view a project video of another LATICRETE SUPERCAP System Solution, visit: https://laticretesupercap.com/en/features-support/project-spotlights/colorado-mills-mall

Related Stories

| Sep 30, 2011

Design your own floor program

Program allows users to choose from a variety of flooring and line accent colors to create unique floor designs to complement any athletic facility.

| Sep 20, 2011

Jeanne Gang wins MacArthur Fellowship

Jeanne Gang, a 2011 MacArthur Fellowship winner described by the foundation as "an architect challenging the aesthetic and technical possibilities of the art form in a wide range of structures."

| Aug 19, 2011

How and why AEC professionals choose flooring systems

Design and construction professionals who completed our flooring survey had strong opinions about their preferred flooring type.

| Aug 19, 2011

Underfloor air distribution, how to get the details right

Our experts provide solid advice on the correct way to design and construct underfloor air distribution systems, to yield significant energy savings.

| Aug 19, 2011

Enhanced acoustical design

Ambient noise levels in some facility types are trending up and becoming a barrier to clear communication between building occupants.

| Mar 21, 2011

Forget planks, new hardwood floors follow tree's curves

Bolefloor offers floorboards, cut using custom algorithms, that follow the natural warp and weft of trees.

| Mar 15, 2011

5 New Trends in Commercial Flooring

Luxury vinyl tile and carpet tile are two flooring categories poised for significant growth. But with all flooring types, “sustainability” is still the watchword.

| Oct 13, 2010

Prefab Trailblazer

The $137 million, 12-story, 500,000-sf Miami Valley Hospital cardiac center, Dayton, Ohio, is the first major hospital project in the U.S. to have made extensive use of prefabricated components in its design and construction.

| Oct 13, 2010

Biloxi’s convention center bigger, better after Katrina

The Mississippi Coast Coliseum and Convention Center in Biloxi is once again open for business following a renovation and expansion necessitated by Hurricane Katrina.

| Aug 11, 2010

New data shows low construction prices may soon be coming to an end

New federal data released recently shows sharp increases in the prices of key construction materials like diesel, copper and brass mill shapes likely foreshadow future increases in construction costs, the Associated General Contractors of America said. The new November producer price index (PPI) report from the Bureau of Labor Statistics provide the strongest indication yet that construction prices are heading up, the association noted.