In the race to develop tech tools to make meaningful efficiency gains in the complex, often-messy commercial construction process, the R&D team at Turner Construction Company has remained keenly focused on one goal: simplicity.

New tools and processes must be easy to execute, by almost anyone in the field, and take advantage of readily accessible data—photos, video—to solve real-world problems. Leave the mind-bogglingly complicated data analysis work to computer scientists like Mani Golparvar-Fard.

Turner’s multi-year partnership with Golparvar-Fard, an Assistant Professor of Engineering and Computer Science at the University of Illinois at Urbana-Champaign, and a former Turner field engineer, has led to the development of breakthrough analytics tools that use structure from motion (SfM) algorithms to make sense of a job site, in real time, using high-definition photos and video.

Now, the technology is being piloted in the field, on the Sacramento Kings’ new 17,500-seat Golden 1 Center project, currently under construction in downtown Sacramento, Calif.

“Over the past 10 years, we’ve built these amazing 4D and 5D BIM models to help us plan our large commercial construction projects,” says Lincoln Wood, Regional Manager, Virtual Design and Construction, based in Turner’s Oakland, Calif., office. “But we still face the challenge of knowing what’s happening out in the field in real time.”

The initial phase of the pilot project involves using aerial drones (right) to document the construction progress. Once the structure goes up, the team will utilize a custom-built rover (left), as well as project engineers, to capture images and video. “The goal is to do this every day,” says Lincoln Wood, Regional Manager, Virtual Design and Construction, with Turner. “With the pilot, we have it down to a week, in time for the weekly work plan.” Courtesy Turner. Click image to enlarge.

The initial phase of the pilot project involves using aerial drones (right) to document the construction progress. Once the structure goes up, the team will utilize a custom-built rover (left), as well as project engineers, to capture images and video. “The goal is to do this every day,” says Lincoln Wood, Regional Manager, Virtual Design and Construction, with Turner. “With the pilot, we have it down to a week, in time for the weekly work plan.” Courtesy Turner. Click image to enlarge.

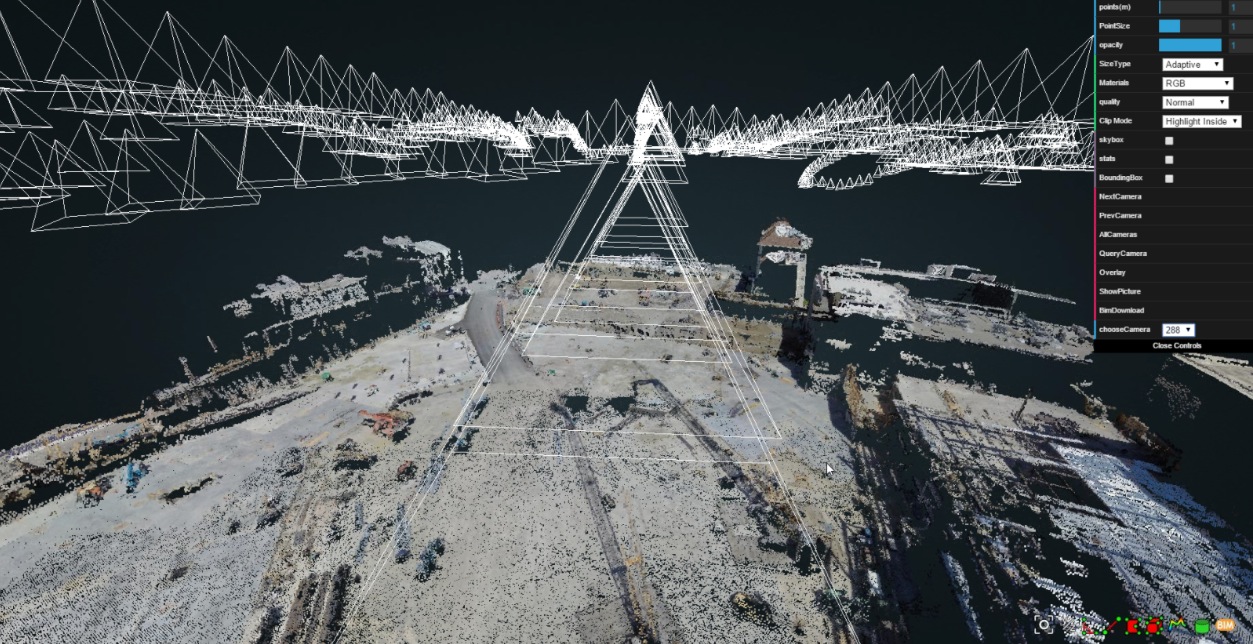

Using proprietary predictive visual data analytics software developed by Golparvar-Fard, the Building Team for the Golden 1 Center project is conducting near-real-time construction progress monitoring using high-resolution photos and video. The initial phase involves reality capture with an aerial drone. As the arena structure goes up, the team will also rely on a camera-equipped land rover (which will be programmed to navigate the interior spaces) and project engineers, who will use smartphones and tablets to gather photos and video.

Once collected, the visual data is stitched together using the SfM algorithm to form a point cloud. The point cloud is then overlaid atop the project’s 4D BIM model to compare and contrast what is happening in the field versus the intended result in the BIM model. (The point cloud creation and BIM overlay work occurs overnight.)

The resulting report is a color-coded 3D visual production model that provides the Building Team with a snapshot of the construction progress, and, most importantly, the areas of the job site that are at risk of falling behind schedule.

By streamlining construction progress monitoring, and providing timely reporting, Wood says the project team has a much deeper level of transparency and improved communication.

“A really good superintendent can see everything in their head; they don’t need a BIM model—it’s in their brain,” says Wood. “Unfortunately, the whole project team does not have that brain. This is a great way for the entire team to see where we are and show what we need to do in order to get back on track and improve the schedule.”

Based on the results of the job site scan and analysis, custom reports are generated for each member of the project management team, including key subcontractors, for the weekly planning meetings.

“The goal is to do this every day,” says Wood. “With the pilot, we have it down to a week, in time for the weekly work plan. We give this report to the team, showing the problem areas and the top-10 risks to the job site. It allows us to visualize and mitigate potential risks to our schedule before they happen.”

Wood says that the enhanced construction progress data may eventually be used for faster and more accurate subcontractor payments, “by removing a lot of the administrative work that happens by having to go back and forth between the job site and the office.”

It also equips the Building Team and owner with “smarter” and more-comprehensive visual documentation of the construction work, by automatically organizing and cataloging thousands of photos and video clips.

“With most jobs, the project engineers are asked to take a bunch of photographs when they’re out in the field, if they have time after their RFIs and submittals are completed for the day,” says Wood. Those images then must be uploaded to the project server, where they are stored with a random code and remain largely unorganized.

“Because our images are stitched together to create a point cloud, we have a better sense of a record of time,” says Wood.

Related Stories

| Jul 11, 2014

Are these LEGO-like blocks the future of construction?

Kite Bricks proposes a more efficient way of building with its newly developed Smart Bricks system.

| Jul 1, 2014

Hyper-speed rendering: How Gensler turns BIM models into beauty shots in seconds

In search of a fast rendering solution, Gensler looked to the gaming and moviemaking industries for the next breakthrough tool: Octane Render.

| Jul 1, 2014

Sochi's 'kinetic façade' may steal the show at the Winter Olympics

The temporary pavilion for Russian telecom operator MegaFon will be wrapped with a massive digital "pin screen" that will morph into the shape of any face.

| Jul 1, 2014

7 ways to cut waste in BIM implementation

Process mapping, split models, and streamlined coordination meetings are among the timesaving techniques AEC firms are employing to improve BIM/VDC workflows.

| Jun 30, 2014

Autodesk acquires design studio The Living, will create Autodesk Studio

The Living, David Benjamin's design studio, has been acquired by Autodesk. Combined, the two will create the Autodesk Studio, which will "create new types of buildings, public installations, prototypes and architectural environments."

| Jun 30, 2014

Report recommends making infrastructure upgrades a cabinet-level priority

The ASCE estimates that $3.6 trillion must be invested by 2020 to make critically needed upgrades and expansions of national infrastructure—and avoid trillions of dollars in lost business sales, exports, disposable income, and GDP.

| Jun 25, 2014

Taking a page from Lean manufacturing for improved design review processes

SPONSORED CONTENT As more building project teams look for ways to collaborate better, technology continues to provide solutions. Yet, as I learned from the experience of one of my customers, choosing the wrong technology can have an underwhelming effect, causing a team to simply swap out old challenges for new ones.

| Jun 18, 2014

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 10, 2014

Site optimization: Paving the way for smoother land development projects

The biggest cost differential when dealing in site development from one site to another is the earthwork. So, when selecting a site, it is critical to not only take into account the initial purchase price of the property, but also what sort of investment it will take to prep the site for development.

Smart Buildings | Jun 8, 2014

Big Data: How one city took control of its facility assets with data

Over the past few years, Buffalo has developed a cutting-edge facility management program to ensure it's utilizing its facilities and operations as efficiently, effectively, and sustainably as possible.